Selection procedure (with example)

I Determine cooling requirements at design conditions.

Given:

Gross Cooling Capacity

Required (TC) . . . . . . . . . . . . . . . . . .39,000 Btuh Sensible Heat Capacity (SHC) . . . . . .30,500 Btuh Temperature of Air Entering Condenser . . . . .95 F Temperature of Air Entering

Evaporator . . . . . . . . . . . . . . . 80 F edb/67 F ewb Evaporator Air Quantity. . . . . . . . . . . . 1,200 cfm

External Static Pressure:

Condenser . . . . . . . . . . . . . . . . . . .0.50 in. wg Evaporator (includes static pressure

drop of

of 0.06 in. wg) . . . . . . . . . . . . . . .0.20 in. wg

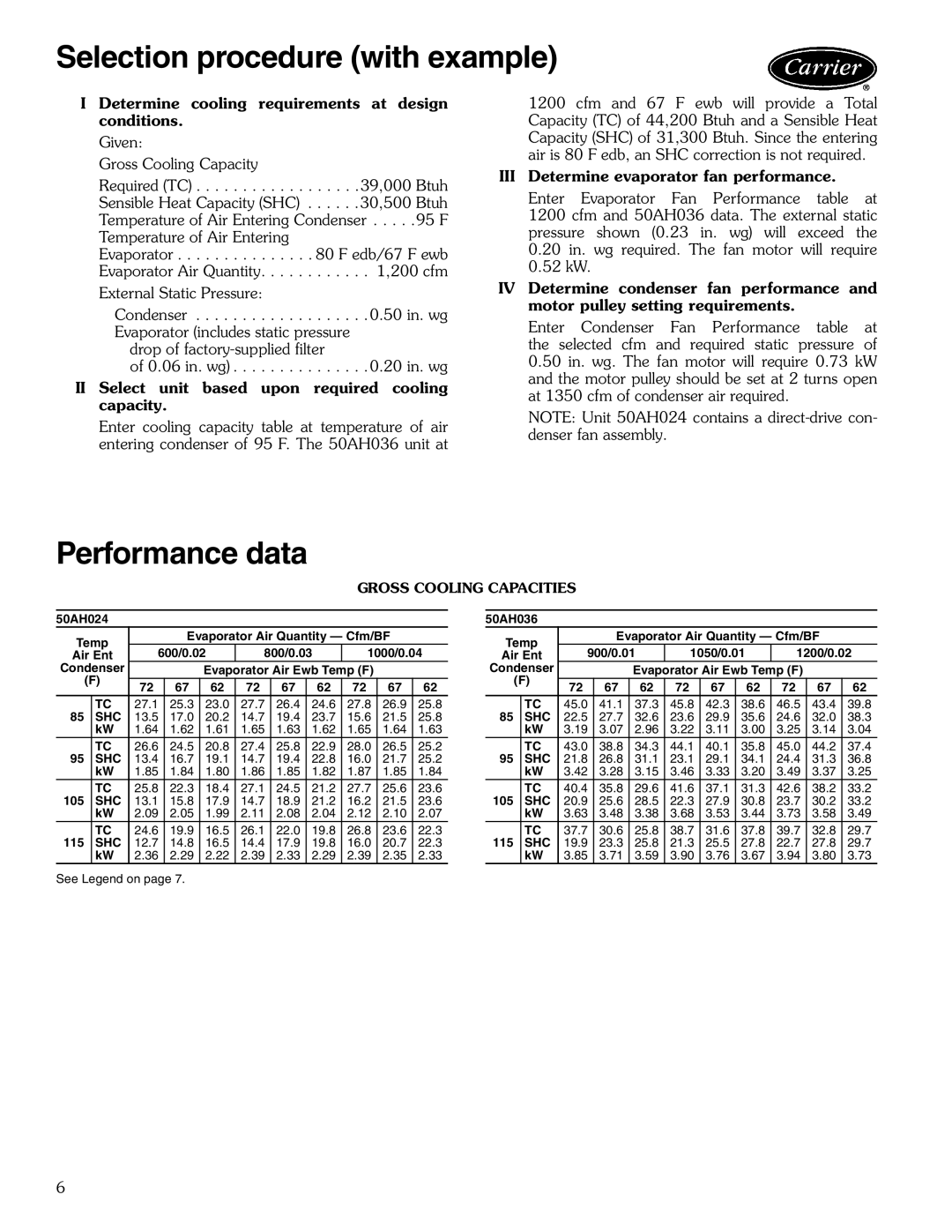

IISelect unit based upon required cooling capacity.

Enter cooling capacity table at temperature of air entering condenser of 95 F. The 50AH036 unit at

1200 cfm and 67 F ewb will provide a Total Capacity (TC) of 44,200 Btuh and a Sensible Heat Capacity (SHC) of 31,300 Btuh. Since the entering air is 80 F edb, an SHC correction is not required.

IIIDetermine evaporator fan performance.

Enter Evaporator Fan Performance table at 1200 cfm and 50AH036 data. The external static pressure shown (0.23 in. wg) will exceed the

0.20in. wg required. The fan motor will require

0.52kW.

IV Determine condenser fan performance and motor pulley setting requirements.

Enter Condenser | Fan Performance table | at |

the selected cfm | and required static pressure | of |

0.50in. wg. The fan motor will require 0.73 kW and the motor pulley should be set at 2 turns open at 1350 cfm of condenser air required.

NOTE: Unit 50AH024 contains a

Performance data

GROSS COOLING CAPACITIES

50AH024

Temp |

| Evaporator Air Quantity — Cfm/BF |

| ||||||||

Air Ent | 600/0.02 | 800/0.03 | 1000/0.04 | ||||||||

Condenser |

|

| Evaporator Air Ewb Temp (F) |

|

| ||||||

| (F) |

|

|

|

|

|

|

|

|

| |

| 72 | 67 | 62 | 72 | 67 | 62 | 72 | 67 | 62 | ||

|

|

| |||||||||

|

| TC | 27.1 | 25.3 | 23.0 | 27.7 | 26.4 | 24.6 | 27.8 | 26.9 | 25.8 |

85 |

| SHC | 13.5 | 17.0 | 20.2 | 14.7 | 19.4 | 23.7 | 15.6 | 21.5 | 25.8 |

|

| kW | 1.64 | 1.62 | 1.61 | 1.65 | 1.63 | 1.62 | 1.65 | 1.64 | 1.63 |

|

| TC | 26.6 | 24.5 | 20.8 | 27.4 | 25.8 | 22.9 | 28.0 | 26.5 | 25.2 |

95 |

| SHC | 13.4 | 16.7 | 19.1 | 14.7 | 19.4 | 22.8 | 16.0 | 21.7 | 25.2 |

|

| kW | 1.85 | 1.84 | 1.80 | 1.86 | 1.85 | 1.82 | 1.87 | 1.85 | 1.84 |

|

| TC | 25.8 | 22.3 | 18.4 | 27.1 | 24.5 | 21.2 | 27.7 | 25.6 | 23.6 |

105 |

| SHC | 13.1 | 15.8 | 17.9 | 14.7 | 18.9 | 21.2 | 16.2 | 21.5 | 23.6 |

|

| kW | 2.09 | 2.05 | 1.99 | 2.11 | 2.08 | 2.04 | 2.12 | 2.10 | 2.07 |

|

| TC | 24.6 | 19.9 | 16.5 | 26.1 | 22.0 | 19.8 | 26.8 | 23.6 | 22.3 |

115 |

| SHC | 12.7 | 14.8 | 16.5 | 14.4 | 17.9 | 19.8 | 16.0 | 20.7 | 22.3 |

|

| kW | 2.36 | 2.29 | 2.22 | 2.39 | 2.33 | 2.29 | 2.39 | 2.35 | 2.33 |

See Legend on page 7.

50AH036

Temp |

| Evaporator Air Quantity — Cfm/BF |

| ||||||||

Air Ent | 900/0.01 | 1050/0.01 | 1200/0.02 | ||||||||

Condenser |

|

| Evaporator Air Ewb Temp (F) |

|

| ||||||

| (F) |

|

|

|

|

|

|

|

|

| |

| 72 | 67 | 62 | 72 | 67 | 62 | 72 | 67 | 62 | ||

|

|

| |||||||||

|

| TC | 45.0 | 41.1 | 37.3 | 45.8 | 42.3 | 38.6 | 46.5 | 43.4 | 39.8 |

85 |

| SHC | 22.5 | 27.7 | 32.6 | 23.6 | 29.9 | 35.6 | 24.6 | 32.0 | 38.3 |

|

| kW | 3.19 | 3.07 | 2.96 | 3.22 | 3.11 | 3.00 | 3.25 | 3.14 | 3.04 |

|

| TC | 43.0 | 38.8 | 34.3 | 44.1 | 40.1 | 35.8 | 45.0 | 44.2 | 37.4 |

95 |

| SHC | 21.8 | 26.8 | 31.1 | 23.1 | 29.1 | 34.1 | 24.4 | 31.3 | 36.8 |

|

| kW | 3.42 | 3.28 | 3.15 | 3.46 | 3.33 | 3.20 | 3.49 | 3.37 | 3.25 |

|

| TC | 40.4 | 35.8 | 29.6 | 41.6 | 37.1 | 31.3 | 42.6 | 38.2 | 33.2 |

105 |

| SHC | 20.9 | 25.6 | 28.5 | 22.3 | 27.9 | 30.8 | 23.7 | 30.2 | 33.2 |

|

| kW | 3.63 | 3.48 | 3.38 | 3.68 | 3.53 | 3.44 | 3.73 | 3.58 | 3.49 |

|

| TC | 37.7 | 30.6 | 25.8 | 38.7 | 31.6 | 37.8 | 39.7 | 32.8 | 29.7 |

115 |

| SHC | 19.9 | 23.3 | 25.8 | 21.3 | 25.5 | 27.8 | 22.7 | 27.8 | 29.7 |

|

| kW | 3.85 | 3.71 | 3.59 | 3.90 | 3.76 | 3.67 | 3.94 | 3.80 | 3.73 |

6