![]() 1/2 ″ STEEL STRAP

1/2 ″ STEEL STRAP

FLEXIBLE | ZONE |

DUCT | DAMPER |

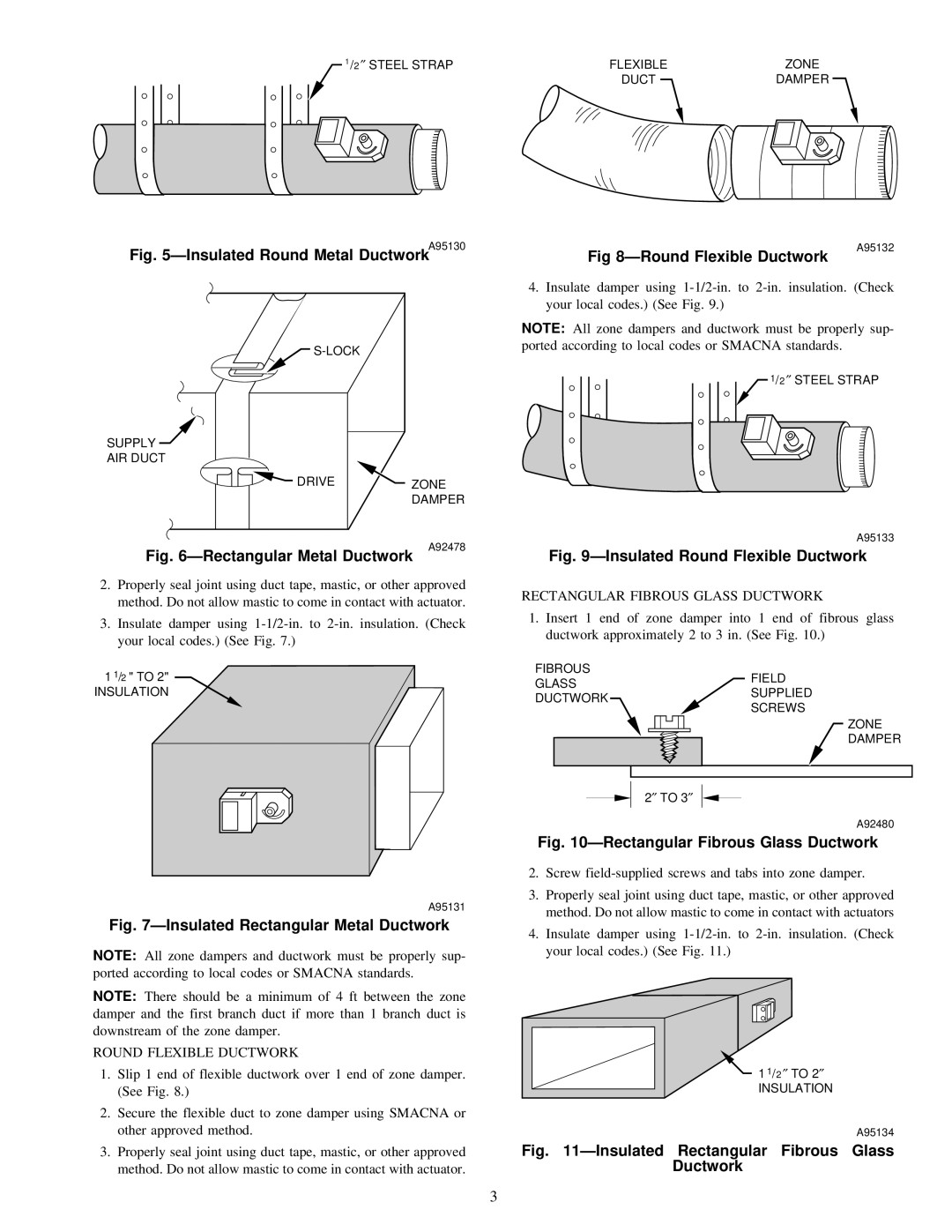

Fig. 5ÐInsulated Round Metal DuctworkA95130

Fig 8ÐRound Flexible Ductwork

A95132

![]() S-LOCK

S-LOCK

SUPPLY![]()

AIR DUCT

![]()

![]()

![]() DRIVE

DRIVE ![]() ZONE

ZONE

DAMPER

4.Insulate damper using

NOTE: All zone dampers and ductwork must be properly sup- ported according to local codes or SMACNA standards.

![]() 1/2 ″ STEEL STRAP

1/2 ″ STEEL STRAP

A95133

Fig. 6ÐRectangular Metal Ductwork

A92478

Fig. 9ÐInsulated Round Flexible Ductwork

2. Properly seal joint using duct tape, mastic, or other approved method. Do not allow mastic to come in contact with actuator.

3. Insulate damper using

1 1/2 " TO 2"

INSULATION

A95131

Fig. 7ÐInsulated Rectangular Metal Ductwork

NOTE: All zone dampers and ductwork must be properly sup- ported according to local codes or SMACNA standards.

NOTE: There should be a minimum of 4 ft between the zone damper and the first branch duct if more than 1 branch duct is downstream of the zone damper.

ROUND FLEXIBLE DUCTWORK

1.Slip 1 end of flexible ductwork over 1 end of zone damper. (See Fig. 8.)

2.Secure the flexible duct to zone damper using SMACNA or other approved method.

3.Properly seal joint using duct tape, mastic, or other approved method. Do not allow mastic to come in contact with actuator.

RECTANGULAR FIBROUS GLASS DUCTWORK

1.Insert 1 end of zone damper into 1 end of fibrous glass ductwork approximately 2 to 3 in. (See Fig. 10.)

FIBROUS

GLASS | FIELD | |

SUPPLIED | ||

DUCTWORK | ||

SCREWS | ||

| ||

| ZONE | |

| DAMPER |

2″ TO 3″

A92480

Fig. 10ÐRectangular Fibrous Glass Ductwork

2.Screw

3.Properly seal joint using duct tape, mastic, or other approved method. Do not allow mastic to come in contact with actuators

4.Insulate damper using

![]() 1 1/2 ″ TO 2″

1 1/2 ″ TO 2″

INSULATION

A95134

Fig. 11ÐInsulated Rectangular Fibrous Glass

Ductwork

3