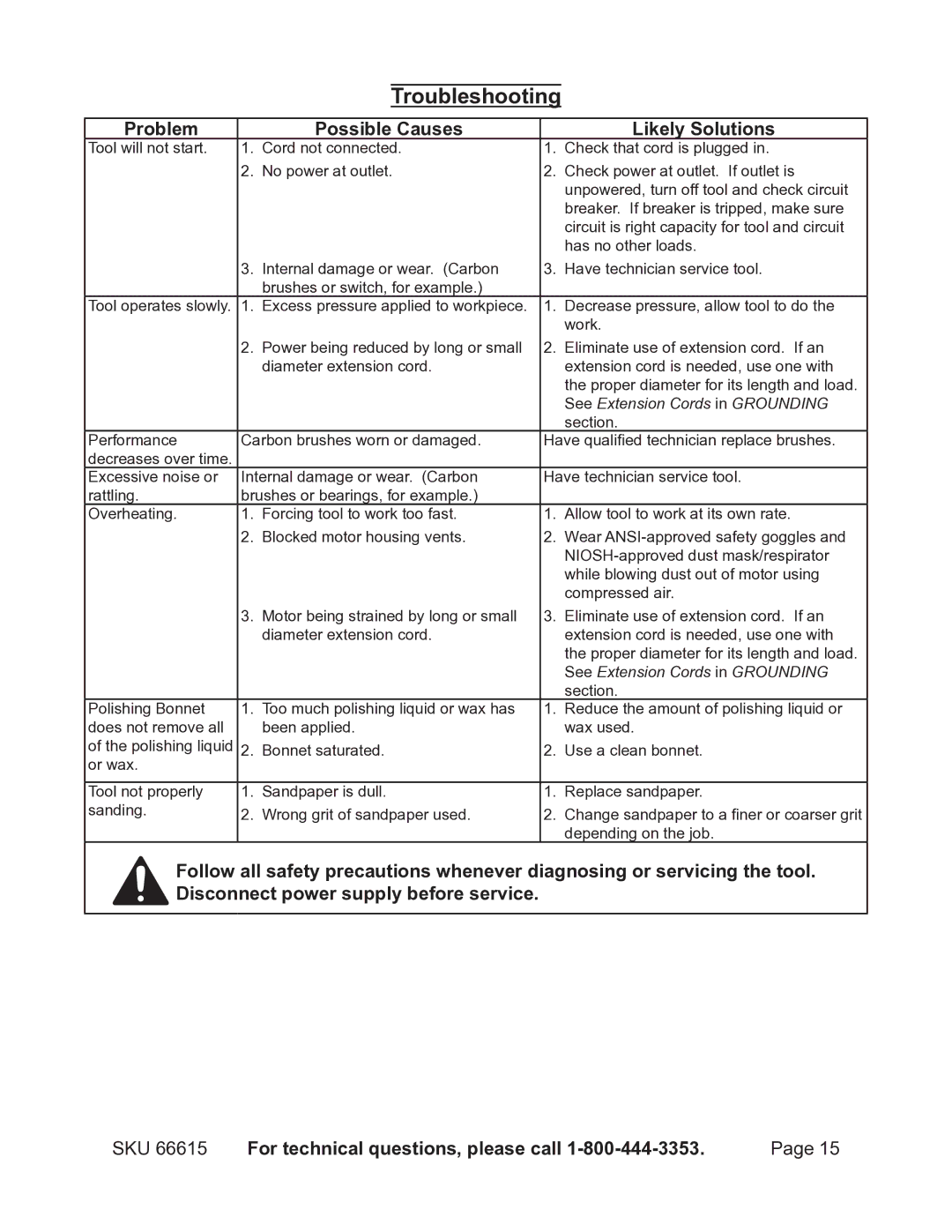

Troubleshooting

Problem |

| Possible Causes |

| Likely Solutions |

Tool will not start. | 1. | Cord not connected. | 1. | Check that cord is plugged in. |

| 2. | No power at outlet. | 2. | Check power at outlet. If outlet is |

|

|

|

| unpowered, turn off tool and check circuit |

|

|

|

| breaker. If breaker is tripped, make sure |

|

|

|

| circuit is right capacity for tool and circuit |

|

|

|

| has no other loads. |

| 3. | Internal damage or wear. (Carbon | 3. | Have technician service tool. |

|

| brushes or switch, for example.) |

|

|

Tool operates slowly. | 1. | Excess pressure applied to workpiece. | 1. Decrease pressure, allow tool to do the | |

|

|

|

| work. |

| 2. | Power being reduced by long or small | 2. | Eliminate use of extension cord. If an |

|

| diameter extension cord. |

| extension cord is needed, use one with |

|

|

|

| the proper diameter for its length and load. |

|

|

|

| See Extension Cords in GROUNDING |

|

|

|

| section. |

Performance | Carbon brushes worn or damaged. | Have qualified technician replace brushes. | ||

decreases over time. |

|

|

|

|

Excessive noise or | Internal damage or wear. (Carbon | Have technician service tool. | ||

rattling. | brushes or bearings, for example.) |

|

| |

Overheating. | 1. | Forcing tool to work too fast. | 1. | Allow tool to work at its own rate. |

| 2. | Blocked motor housing vents. | 2. | Wear |

|

|

|

| |

|

|

|

| while blowing dust out of motor using |

|

|

|

| compressed air. |

| 3. | Motor being strained by long or small | 3. | Eliminate use of extension cord. If an |

|

| diameter extension cord. |

| extension cord is needed, use one with |

|

|

|

| the proper diameter for its length and load. |

|

|

|

| See Extension Cords in GROUNDING |

|

|

|

| section. |

Polishing Bonnet | 1. | Too much polishing liquid or wax has | 1. | Reduce the amount of polishing liquid or |

does not remove all |

| been applied. |

| wax used. |

of the polishing liquid | 2. | Bonnet saturated. | 2. | Use a clean bonnet. |

or wax. |

|

|

|

|

|

|

|

|

|

Tool not properly | 1. | Sandpaper is dull. | 1. | Replace sandpaper. |

sanding. | 2. | Wrong grit of sandpaper used. | 2. | Change sandpaper to a finer or coarser grit |

|

|

|

| depending on the job. |

Follow all safety precautions whenever diagnosing or servicing the tool. Disconnect power supply before service.

SKU 66615 | For technical questions, please call | Page 15 |