9.To determine the proper Acetylene Regulator (parts

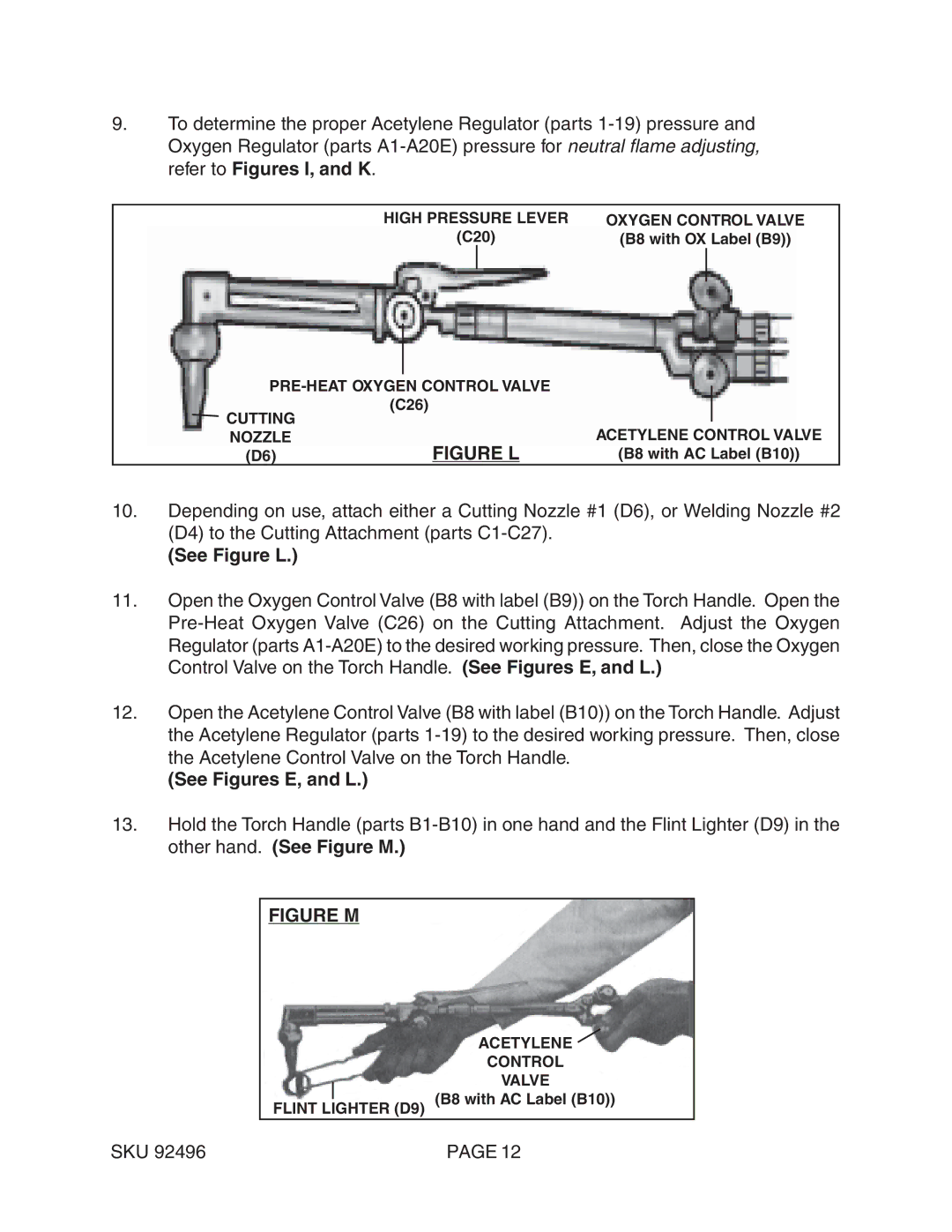

HIGH PRESSURE LEVER | OXYGEN CONTROL VALVE |

(C20) | (B8 with OX Label (B9)) |

| ||

CUTTING | (C26) |

|

| ACETYLENE CONTROL VALVE | |

NOZZLE | FIGURE L | |

(D6) | (B8 with AC Label (B10)) | |

10.Depending on use, attach either a Cutting Nozzle #1 (D6), or Welding Nozzle #2 (D4) to the Cutting Attachment (parts

(See Figure L.)

11.Open the Oxygen Control Valve (B8 with label (B9)) on the Torch Handle. Open the

12.Open the Acetylene Control Valve (B8 with label (B10)) on the Torch Handle. Adjust the Acetylene Regulator (parts

(See Figures E, and L.)

13.Hold the Torch Handle (parts

FIGURE M

FLINT LIGHTER (D9)

ACETYLENE ![]() CONTROL

CONTROL

VALVE

(B8 with AC Label (B10))

SKU 92496 | PAGE 12 |