Maintenance

Lubrication

1.All moving parts within the Electric Winch have been lubricated using high temperature lithium grease at the factory. No internal lubrication is required.

2.Lubricate the cable portion of the Cable Assembly (36) periodically using a light penetrat- ing oil.

Cable Assembly Replacement

1.Move Cam Ring (11) to the OUT position.

2.Extend Cable Assembly (36) to its full length.

Note how the existing cable is connected to the inside of the drum.

3.Remove old Cable Assembly and attach new one.

Caution: Do not replace with inferior cable. Always use the approved replace- ment part from Harbor Freight Tools.

4.Retract Cable Assembly onto cable drum being careful not to allow kinking.

5.Cover the Cable Assembly and Electric Winch when not in use.

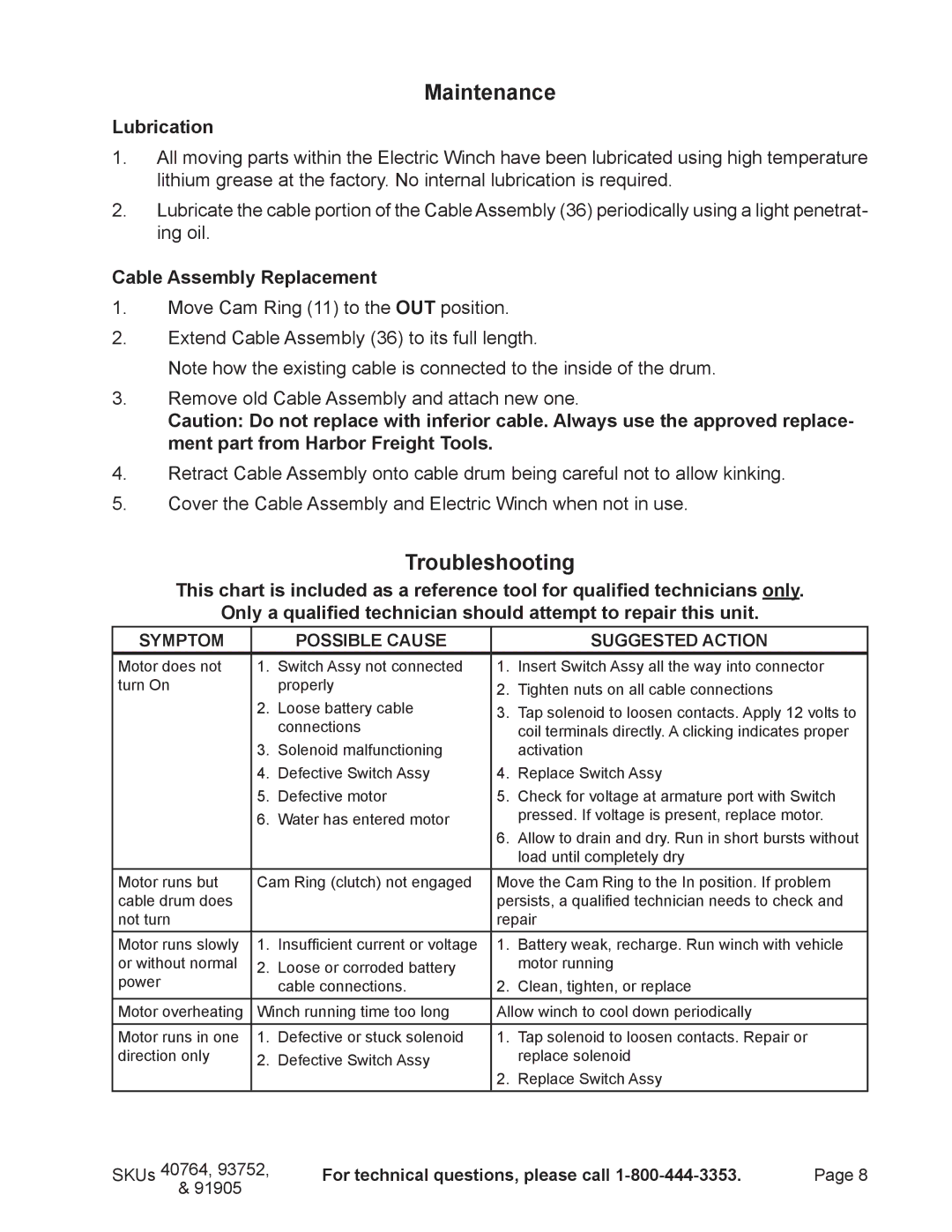

Troubleshooting

This chart is included as a reference tool for qualified technicians only.

Only a qualified technician should attempt to repair this unit.

SYMPTOM |

| POSSIBLE CAUSE |

| SUGGESTED ACTION |

Motor does not | 1. | Switch Assy not connected | 1. | Insert Switch Assy all the way into connector |

turn On |

| properly | 2. | Tighten nuts on all cable connections |

| 2. | Loose battery cable | 3. | Tap solenoid to loosen contacts. Apply 12 volts to |

|

| connections |

| coil terminals directly. A clicking indicates proper |

| 3. | Solenoid malfunctioning |

| activation |

| 4. | Defective Switch Assy | 4. | Replace Switch Assy |

| 5. | Defective motor | 5. | Check for voltage at armature port with Switch |

| 6. | Water has entered motor |

| pressed. If voltage is present, replace motor. |

|

|

| 6. | Allow to drain and dry. Run in short bursts without |

|

|

|

| load until completely dry |

Motor runs but | Cam Ring (clutch) not engaged | Move the Cam Ring to the In position. If problem | ||

cable drum does |

|

| persists, a qualified technician needs to check and | |

not turn |

|

| repair | |

Motor runs slowly | 1. | Insufficient current or voltage | 1. | Battery weak, recharge. Run winch with vehicle |

or without normal | 2. | Loose or corroded battery |

| motor running |

power |

| cable connections. | 2. | Clean, tighten, or replace |

Motor overheating | Winch running time too long | Allow winch to cool down periodically | ||

Motor runs in one | 1. | Defective or stuck solenoid | 1. | Tap solenoid to loosen contacts. Repair or |

direction only | 2. | Defective Switch Assy |

| replace solenoid |

|

|

| 2. | Replace Switch Assy |

SKUs 40764, 93752, | For technical questions, please call | Page 8 |

& 91905 |

|

|