INSTALLATION

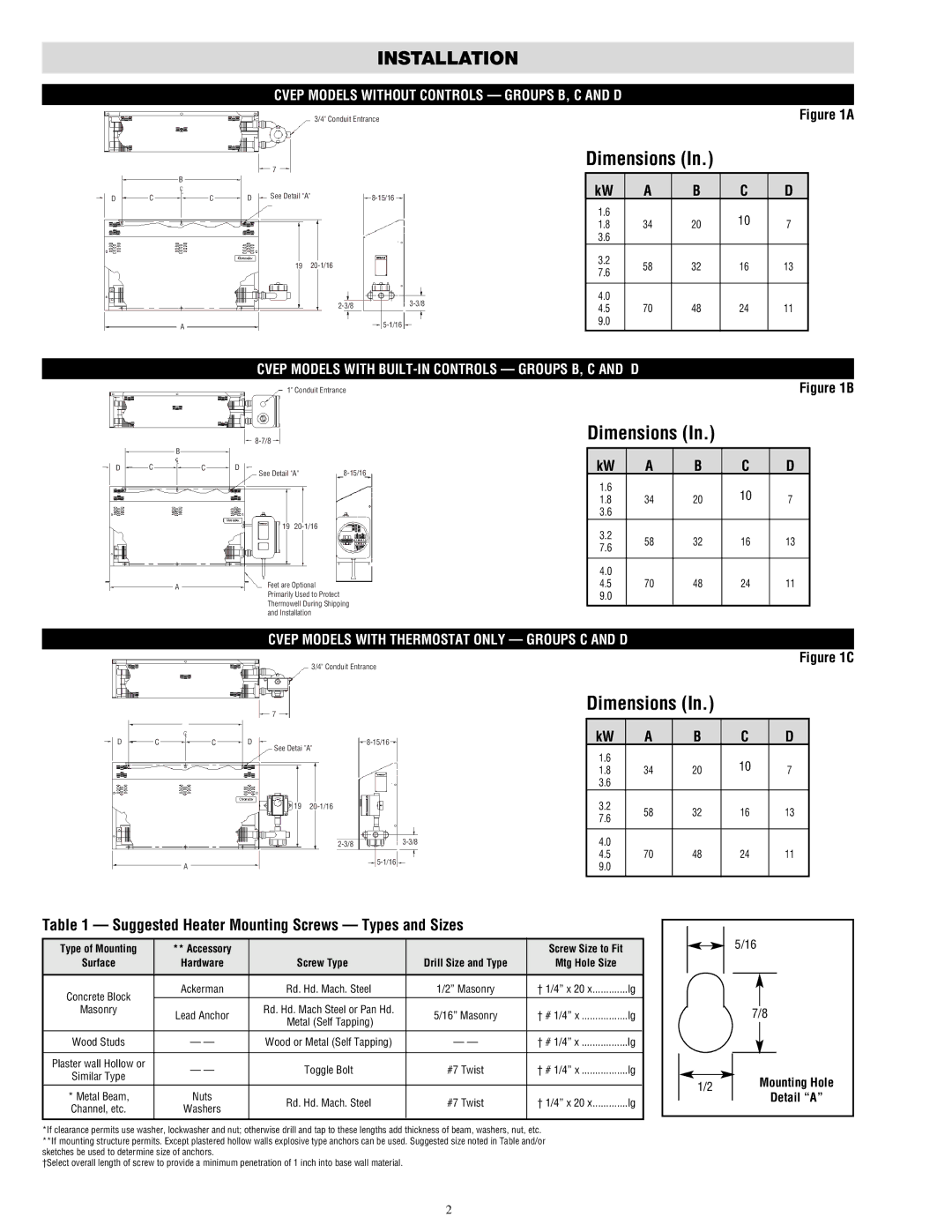

CVEP MODELS WITHOUT CONTROLS — GROUPS B, C AND D

3/4" Conduit Entrance

7

B

D | C | C | D | See Detail "A" |

19

A |

Figure 1A

Dimensions (In.)

kW | A | B | C | D | |

1.6 |

|

| 10 |

| |

1.8 | 34 | 20 | 7 | ||

3.6 |

|

|

|

| |

3.2 | 58 | 32 | 16 | 13 | |

7.6 | |||||

|

|

|

| ||

|

|

|

|

| |

4.0 |

|

|

|

| |

4.5 | 70 | 48 | 24 | 11 | |

9.0 |

|

|

|

|

CVEP MODELS WITH BUILT-IN CONTROLS — GROUPS B, C AND D

|

|

|

| 1" Conduit Entrance | |

|

|

|

|

| |

|

| B |

|

| |

D | C |

| C | D | |

|

|

|

| See Detail "A" | |

|

|

|

| 19 |

|

|

|

|

| Feet are Optional |

|

|

| A |

| ||

|

|

|

| Primarily Used to Protect |

|

Thermowell During Shipping

and Installation

Figure 1B

Dimensions (In.)

kW | A | B | C | D | |

1.6 |

|

| 10 |

| |

1.8 | 34 | 20 | 7 | ||

3.6 |

|

|

|

| |

3.2 | 58 | 32 | 16 | 13 | |

7.6 | |||||

|

|

|

| ||

|

|

|

|

| |

4.0 |

|

|

|

| |

4.5 | 70 | 48 | 24 | 11 | |

9.0 |

|

|

|

|

CVEP MODELS WITH THERMOSTAT ONLY — GROUPS C AND D

3/4" Conduit Entrance

7

D | C | C | D | |

|

|

|

| See Detai "A" |

19

Figure 1C

Dimensions (In.)

kW | A | B | C | D | |

1.6 |

|

| 10 |

| |

1.8 | 34 | 20 | 7 | ||

3.6 |

|

|

|

| |

3.2 | 58 | 32 | 16 | 13 | |

7.6 | |||||

|

|

|

| ||

|

|

|

|

| |

4.0 |

|

|

|

| |

4.5 | 70 | 48 | 24 | 11 |

A

9.0 |

Table 1 — Suggested Heater Mounting Screws — Types and Sizes

Type of Mounting | ** Accessory |

|

| Screw Size to Fit |

| |

Surface | Hardware | Screw Type | Drill Size and Type | Mtg Hole Size |

| |

|

|

|

|

|

| |

Concrete Block | Ackerman | Rd. Hd. Mach. Steel | 1/2” Masonry | † 1/4” x 20 x | lg | |

|

|

|

|

| ||

|

|

|

|

| ||

Masonry | Lead Anchor | Rd. Hd. Mach Steel or Pan Hd. | 5/16” Masonry | † # 1/4” x | lg | |

| Metal (Self Tapping) | |||||

|

|

|

|

| ||

Wood Studs | — — | Wood or Metal (Self Tapping) | — — | † # 1/4” x | lg | |

|

|

|

|

|

| |

Plaster wall Hollow or | — — | Toggle Bolt | #7 Twist | † # 1/4” x | lg | |

Similar Type | ||||||

|

|

|

|

| ||

|

|

|

|

|

| |

* Metal Beam, | Nuts | Rd. Hd. Mach. Steel | #7 Twist | † 1/4” x 20 x | lg | |

Channel, etc. | Washers | |||||

|

|

|

| |||

|

|

|

|

|

|

5/16

7/8

|

|

|

|

|

|

|

|

|

|

1/2 |

|

| Mounting Hole | |

|

| Detail “A” | ||

|

|

| ||

|

| |||

|

|

|

|

|

*If clearance permits use washer, lockwasher and nut; otherwise drill and tap to these lengths add thickness of beam, washers, nut, etc. **If mounting structure permits. Except plastered hollow walls explosive type anchors can be used. Suggested size noted in Table and/or sketches be used to determine size of anchors.

†Select overall length of screw to provide a minimum penetration of 1 inch into base wall material.

2