KETTLE VENTING

INSTRUCTIONS

|

| 150 | 200 |

| Pressure |

| 100 | 250 |

| ||

|

| 20 |

| Gauge | |

50 | 30 |

| |||

10 | 40 | 300 |

| ||

|

|

| |||

|

|

| Pressure | ||

0 | I |

| 50 |

| |

0 |

|

|

|

| |

| R |

|

| 350 | Relief |

| A |

|

| ||

| E |

|

|

| |

| T |

|

|

|

|

| N |

| 60 |

| Valve |

| V |

| 400 | ||

|

| psi | |||

kPa

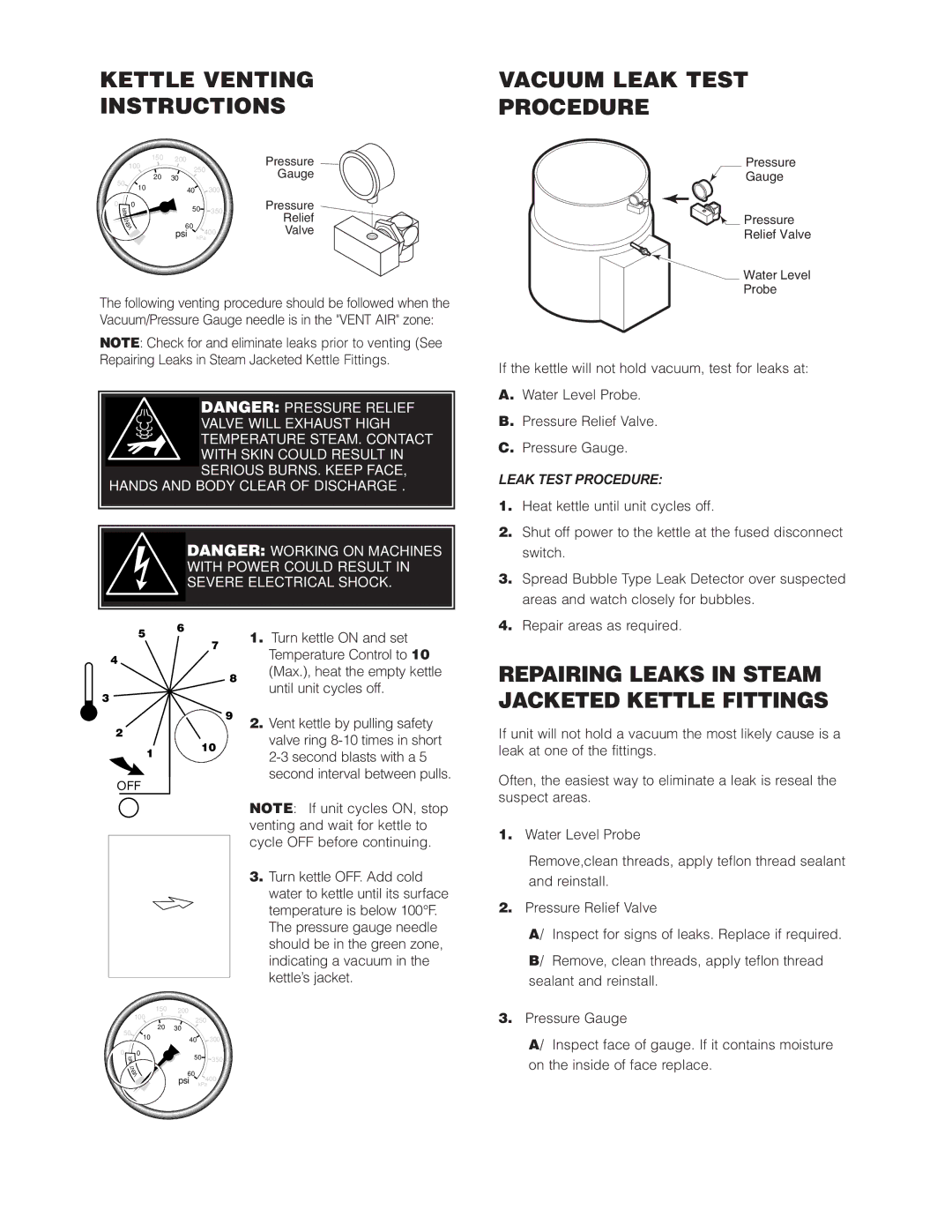

The following venting procedure should be followed when the Vacuum/Pressure Gauge needle is in the "VENT AIR" zone:

NOTE: Check for and eliminate leaks prior to venting (See Repairing Leaks in Steam Jacketed Kettle Fittings.

DANGER: PRESSURE RELIEF VALVE WILL EXHAUST HIGH TEMPERATURE STEAM. CONTACT WITH SKIN COULD RESULT IN SERIOUS BURNS. KEEP FACE,

HANDS AND BODY CLEAR OF DISCHARGE.

DANGER: WORKING ON MACHINES

WITH POWER COULD RESULT IN

SEVERE ELECTRICAL SHOCK.

VACUUM LEAK TEST

PROCEDURE

Pressure

![]() Gauge

Gauge

Pressure |

Relief Valve |

![]() Water Level

Water Level

Probe

If the kettle will not hold vacuum, test for leaks at:

A.Water Level Probe.

B.Pressure Relief Valve.

C.Pressure Gauge.

LEAK TEST PROCEDURE:

1. | Heat kettle until unit cycles off. |

2. | Shut off power to the kettle at the fused disconnect |

| switch. |

3. | Spread Bubble Type Leak Detector over suspected |

| areas and watch closely for bubbles. |

5 6

7

4

8

3 |

|

| 9 |

2 |

|

1 | 10 |

| |

OFF |

|

1.Turn kettle ON and set Temperature Control to 10 (Max.), heat the empty kettle until unit cycles off.

2.Vent kettle by pulling safety valve ring

4. Repair areas as required. |

REPAIRING LEAKS IN STEAM JACKETED KETTLE FITTINGS

If unit will not hold a vacuum the most likely cause is a leak at one of the fittings.

Often, the easiest way to eliminate a leak is reseal the suspect areas.

NOTE: If unit cycles ON, stop venting and wait for kettle to cycle OFF before continuing.

3.Turn kettle OFF. Add cold water to kettle until its surface temperature is below 100°F. The pressure gauge needle should be in the green zone, indicating a vacuum in the kettle’s jacket.

| 150 | 200 |

| |

100 | 250 |

| ||

| 20 |

| ||

50 | 30 |

| ||

10 | 40 | 300 | ||

| ||||

|

| |||

0 |

| 50 |

| |

I |

|

| ||

R |

|

| 350 | |

A |

|

| ||

T |

|

|

| |

N |

| 60 |

| |

E |

|

|

| |

V |

|

|

| |

1.Water Level Probe

Remove,clean threads, apply teflon thread sealant

and reinstall.

2.Pressure Relief Valve

A/ Inspect for signs of leaks. Replace if required.

B/ Remove, clean threads, apply teflon thread

sealant and reinstall.

3.Pressure Gauge

A/ Inspect face of gauge. If it contains moisture

on the inside of face replace.

psi 400

kPa