INSTALLATION

INSPECTION

Before unpacking visually inspect the unit for evidence of damage during shipping.

If damage is noticed, do not unpack the unit, follow shipping damage instructions.

SHIPPING DAMAGE

INSTRUCTIONS

If shipping damage to the unit is discovered or suspected, observe the following guidelines in preparing a shipping damage claim.

1.Write down a description of the damage or the reason for suspecting damage as soon as it is discovered. This will help in filling out the claim forms later.

2.As soon as damage is discovered or suspected, notify the carrier that delivered the shipment.

3.Arrange for the carrier's representative to examine the damage.

4.Fill out all carrier claims forms and have the examining carrier sign and date each form.

GENERAL

Installation of the kettle must be accomplished by qualified installation personnel working to all applicable local and national codes. Improper installation of product could cause injury or damage.

This equipment is built to comply with applicable standards for manufacturers. Included among those approval agencies are: UL, A.G.A., NSF, ASME/N.Bd., CSA, CGA, ETL, and others. Many local codes exist, and it is the responsibility of the owner/installer to comply with these codes.

Observe all clearance requirements to provide proper

Dimensions and clearance specifications are shown on the specification sheet and in the Clearance Requirements section.

CLEARANCE REQUIREMENTS

CLEARANCE REQUIREMENTS TO COMBUSTIBLE AND NONCOMBUSTIBLE SURFACES.

Model # | Back | Left Side | Right Side |

|

|

|

|

4” | 0 | 0 | |

4” | 0 | 0 | |

|

|

|

|

NOTE: To prevent removal of unit for servicing, allow sufficient room on right hand side for servicing.

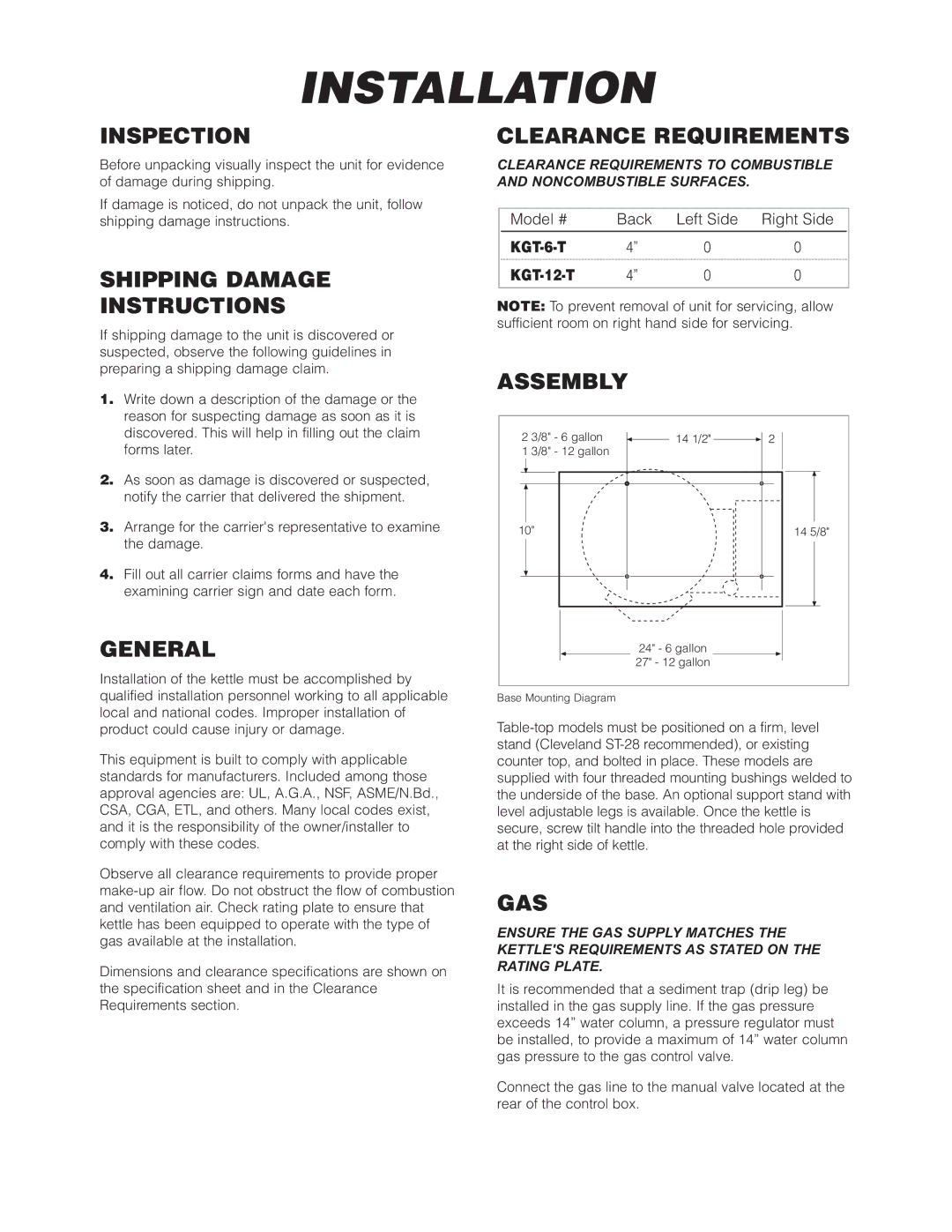

ASSEMBLY |

|

| |

2 | 3/8" - 6 gallon | 14 1/2" | 2 |

1 | 3/8" - 12 gallon |

|

|

10" |

| 14 5/8" | |

|

| 24" - 6 gallon |

|

|

| 27" - 12 gallon |

|

Base Mounting Diagram

GAS

ENSURE THE GAS SUPPLY MATCHES THE KETTLE'S REQUIREMENTS AS STATED ON THE RATING PLATE.

It is recommended that a sediment trap (drip leg) be installed in the gas supply line. If the gas pressure exceeds 14” water column, a pressure regulator must be installed, to provide a maximum of 14” water column gas pressure to the gas control valve.

Connect the gas line to the manual valve located at the rear of the control box.