WCF1411-A specifications

The Cornelius WCF1411-A is a high-performance beverage dispensing system designed to meet the demands of both commercial and light industrial applications. This innovative unit serves as an ideal solution for businesses looking to provide a variety of cold beverages efficiently and effectively.One of the standout features of the WCF1411-A is its capacity to dispense multiple beverages from a single unit. With the ability to host numerous flavor options, this system caters to diverse consumer preferences. Operators can select from a range of beverages, including soft drinks, flavored waters, and even iced coffees, making it a versatile addition to any beverage service setup. This capability not only enhances customer satisfaction but also streamlines inventory management.

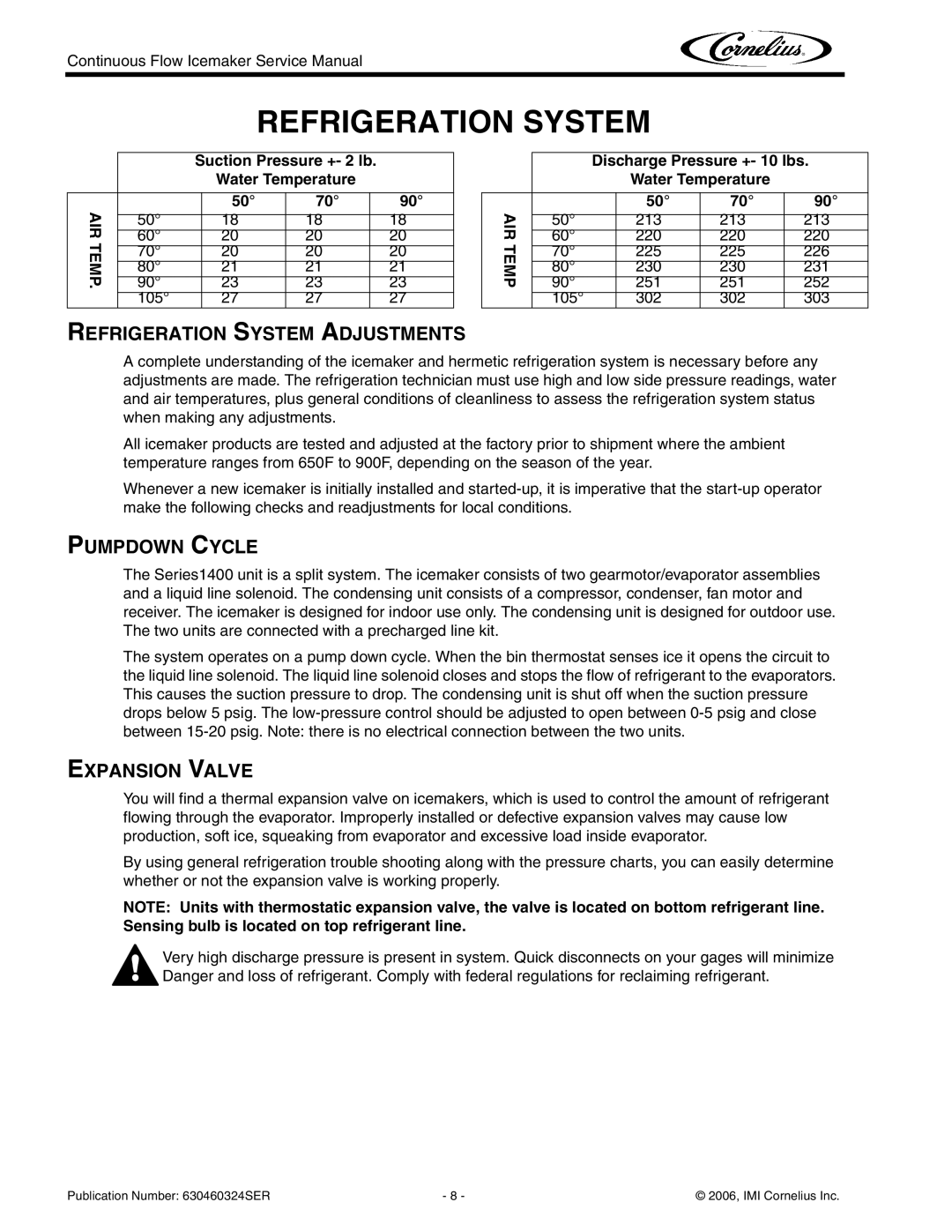

The WCF1411-A utilizes advanced cooling technology, ensuring that drinks are consistently chilled to the perfect serving temperature. This is achieved through its efficient refrigeration system, which minimizes energy consumption while maintaining optimal performance. The dual-cooled setup provides precise temperature control, ensuring that each beverage is served refreshing, enhancing the overall quality and flavor.

Moreover, the Cornelius WCF1411-A is designed with user-friendly features. The intuitive interface simplifies the dispensing process, allowing staff to quickly serve beverages with minimal training. Additionally, the unit is equipped with a durable stainless steel construction, which not only increases its longevity but also makes it easy to clean and maintain. This durability is particularly useful in high-traffic environments, where the system is subjected to regular use.

Another notable characteristic of the WCF1411-A is its compact design. This makes it suitable for spaces with limited room, such as small restaurants, cafes, and convenience stores. Despite its smaller footprint, the system does not compromise on performance, delivering similar capabilities to larger units.

Furthermore, the WCF1411-A is compatible with various beverage mixers, allowing operators to expand their offerings with ease. Its flexible connectivity options enable integration with existing systems, providing seamless operation within various environments.

In conclusion, the Cornelius WCF1411-A stands out as a reliable and efficient beverage dispensing solution. With its multi-beverage capability, advanced cooling technology, user-friendly features, durable construction, and compact design, it addresses the needs of modern beverage service operators, ensuring delightful drink experiences for customers while maximizing operational efficiency.