OPERATION cont.

OPERATION cont.

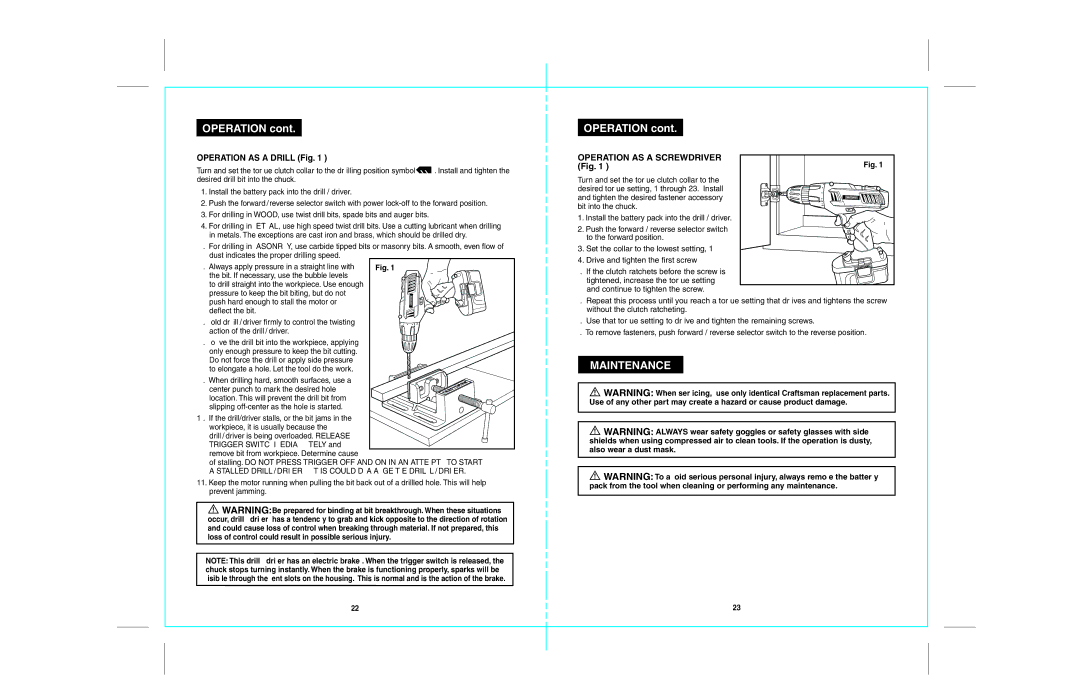

OPERATION AS A DRILL (Fig. 15)

Turn and set the torque clutch collar to the drilling position symbol![]() . Install and tighten the desired drill bit into the chuck.

. Install and tighten the desired drill bit into the chuck.

1.Install the battery pack into the drill / driver.

2.Push the forward/reverse selector switch with power

3.For drilling in WOOD, use twist drill bits, spade bits and auger bits.

4.For drilling in METAL, use high speed twist drill bits. Use a cutting lubricant when drilling in metals. The exceptions are cast iron and brass, which should be drilled dry.

5.For drilling in MASONRY, use carbide tipped bits or masonry bits. A smooth, even flow of dust indicates the proper drilling speed.

6. Always apply pressure in a straight line with | Fig. 15 |

the bit. If necessary, use the bubble levels |

|

to drill straight into the workpiece. Use enough |

|

pressure to keep the bit biting, but do not |

|

OPERATION AS A SCREWDRIVER (Fig. 16)

Turn and set the torque clutch collar to the desired torque setting, 1 through 23. Install and tighten the desired fastener accessory bit into the chuck.

1.Install the battery pack into the drill / driver.

2.Push the forward / reverse selector switch to the forward position.

3.Set the collar to the lowest setting, “1”

4.Drive and tighten the first screw

5.If the clutch ratchets before the screw is tightened, increase the torque setting and continue to tighten the screw.

Fig. 16 |

9 |

7 |

5 |

3 |

1 |

push hard enough to stall the motor or |

|

|

|

|

|

deflect the bit. |

|

|

|

|

|

7. Hold drill /driver firmly to control the twisting | 9 | 7 | 5 | 3 | 1 |

action of the drill/ driver. |

|

|

|

|

|

8.Move the drill bit into the workpiece, applying ![]() only enough pressure to keep the bit cutting.

only enough pressure to keep the bit cutting.

Do not force the drill or apply side pressure![]() to elongate a hole. Let the tool do the work.

to elongate a hole. Let the tool do the work.![]()

![]()

9.When drilling hard, smooth surfaces, use a ![]()

![]()

![]()

![]()

![]()

![]() center punch to mark the desired hole

center punch to mark the desired hole![]()

![]()

![]()

![]()

![]()

![]()

![]() location. This will prevent the drill bit from

location. This will prevent the drill bit from![]()

![]()

![]()

![]()

![]() slipping

slipping ![]()

![]()

![]()

![]()

![]()

10.If the drill/driver stalls, or the bit jams in the![]() workpiece, it is usually because the

workpiece, it is usually because the![]()

drill /driver is being overloaded. RELEASE![]() TRIGGER SWITCH IMMEDIATELY and

TRIGGER SWITCH IMMEDIATELY and![]()

remove bit from workpiece. Determine cause

of stalling. DO NOT PRESS TRIGGER OFF AND ON IN AN ATTEMPT TO START A STALLED DRILL /DRIVER – THIS COULD DAMAGE THE DRILL /DRIVER.

11.Keep the motor running when pulling the bit back out of a drillled hole. This will help prevent jamming.

!WARNING:Be prepared for binding at bit breakthrough. When these situations occur, drill / driver has a tendency to grab and kick opposite to the direction of rotation and could cause loss of control when breaking through material. If not prepared, this loss of control could result in possible serious injury.

NOTE: This drill / driver has an electric brake. When the trigger switch is released, the chuck stops turning instantly. When the brake is functioning properly, sparks will be visible through the vent slots on the housing. This is normal and is the action of the brake.

6.Repeat this process until you reach a torque setting that drives and tightens the screw without the clutch ratcheting.

7.Use that torque setting to drive and tighten the remaining screws.

8.To remove fasteners, push forward / reverse selector switch to the reverse position.

MAINTENANCE

!WARNING: When servicing, use only identical Craftsman replacement parts. Use of any other part may create a hazard or cause product damage.

!WARNING: ALWAYS wear safety goggles or safety glasses with side shields when using compressed air to clean tools. If the operation is dusty, also wear a dust mask.

!WARNING: To avoid serious personal injury, always remove the battery pack from the tool when cleaning or performing any maintenance.

22 | 23 |