OPERATION

! WARNING: A |

larger than |

OPERATION cont.

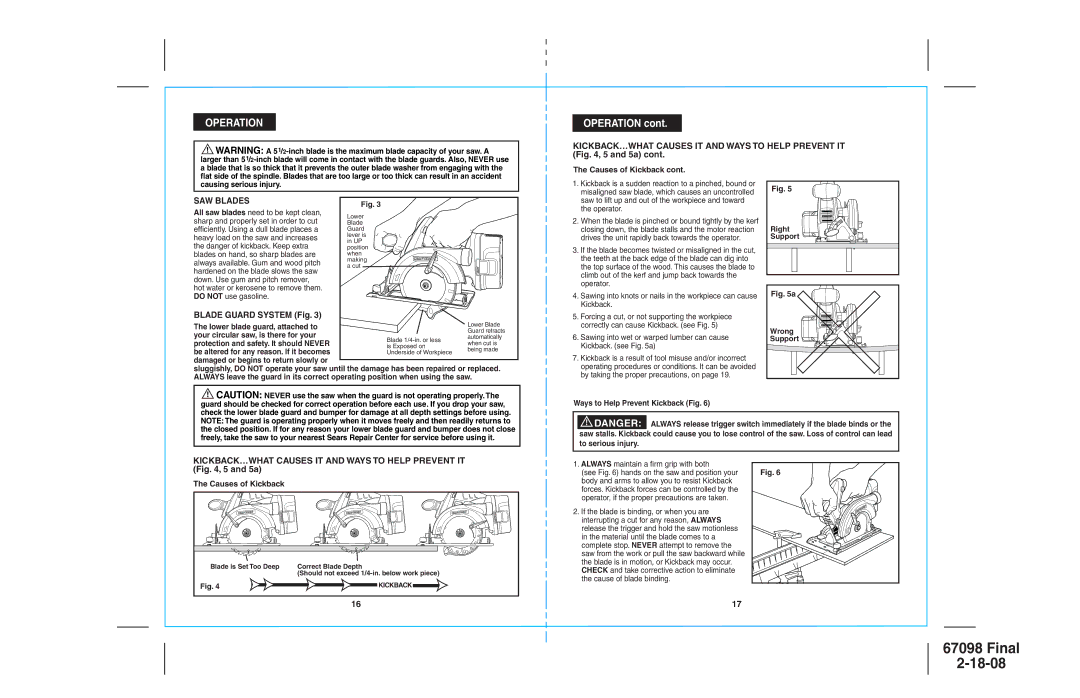

KICKBACK…WHAT CAUSES IT AND WAYS TO HELP PREVENT IT (Fig. 4, 5 and 5a) cont.

a blade that is so thick that it prevents the outer blade washer from engaging with the |

flat side of the spindle. Blades that are too large or too thick can result in an accident |

causing serious injury. |

SAW BLADES

All saw blades need to be kept clean, sharp and properly set in order to cut efficiently. Using a dull blade places a heavy load on the saw and increases the danger of kickback. Keep extra blades on hand, so sharp blades are always available. Gum and wood pitch hardened on the blade slows the saw down. Use gum and pitch remover, hot water or kerosene to remove them. DO NOT use gasoline.

BLADE GUARD SYSTEM (Fig. 3) |

|

|

| |

The lower blade guard, attached to |

|

| Lower Blade | |

|

| |||

your circular saw, is there for your |

|

| Guard retracts | |

Blade | automatically | |||

protection and safety. It should NEVER | when cut is | |||

is Exposed on | ||||

be altered for any reason. If it becomes | Underside of Workpiece | being made | ||

damaged or begins to return slowly or |

|

|

| |

|

|

| ||

sluggishly, DO NOT operate your saw until the damage has been repaired or replaced. ALWAYS leave the guard in its correct operating position when using the saw.

The Causes of Kickback cont.

1.Kickback is a sudden reaction to a pinched, bound or misaligned saw blade, which causes an uncontrolled saw to lift up and out of the workpiece and toward the operator.

2.When the blade is pinched or bound tightly by the kerf closing down, the blade stalls and the motor reaction drives the unit rapidly back towards the operator.

3.If the blade becomes twisted or misaligned in the cut, the teeth at the back edge of the blade can dig into the top surface of the wood. This causes the blade to climb out of the kerf and jump back towards the operator.

4.Sawing into knots or nails in the workpiece can cause Kickback.

5.Forcing a cut, or not supporting the workpiece correctly can cause Kickback. (see Fig. 5)

6.Sawing into wet or warped lumber can cause Kickback. (see Fig. 5a)

7.Kickback is a result of tool misuse and/or incorrect operating procedures or conditions. It can be avoided by taking the proper precautions, on page 19.

Fig. 5

Right Support

Fig. 5a

Wrong Support

![]() 50

50 ![]() 40

40 ![]()

![]()

30 22 20

![]() 0

0

![]() 50

50 ![]() 40

40 ![]()

![]()

30 22 20

![]() 0

0

!CAUTION: NEVER use the saw when the guard is not operating properly. The guard should be checked for correct operation before each use. If you drop your saw, check the lower blade guard and bumper for damage at all depth settings before using. NOTE: The guard is operating properly when it moves freely and then readily returns to the closed position. If for any reason your lower blade guard and bumper does not close freely, take the saw to your nearest Sears Repair Center for service before using it.

Ways to Help Prevent Kickback (Fig. 6)

!DANGER: ALWAYS release trigger switch immediately if the blade binds or the saw stalls. Kickback could cause you to lose control of the saw. Loss of control can lead to serious injury.

KICKBACK…WHAT CAUSES IT AND WAYS TO HELP PREVENT IT (Fig. 4, 5 and 5a)

The Causes of Kickback

Blade is Set Too Deep | Correct Blade Depth |

| (Should not exceed |

Fig. 4 | KICKBACK |

1.ALWAYS maintain a firm grip with both

(see Fig. 6) hands on the saw and position your body and arms to allow you to resist Kickback forces. Kickback forces can be controlled by the operator, if the proper precautions are taken.

2.If the blade is binding, or when you are interrupting a cut for any reason, ALWAYS release the trigger and hold the saw motionless in the material until the blade comes to a complete stop. NEVER attempt to remove the saw from the work or pull the saw backward while the blade is in motion, or Kickback may occur. CHECK and take corrective action to eliminate the cause of blade binding.

Fig. 6 |

16 |

17