•Remove the two flange nuts (and hex bolts) which secure the hopper support bracket to the impeller housing. Retain the hardware. See Figure 19.

Support | Flange Nuts | |

Bracket | ||

|

Figure 19

•Pivot the shredder screen upward as instructed under the heading Cleaning the Reduction

Chamber.

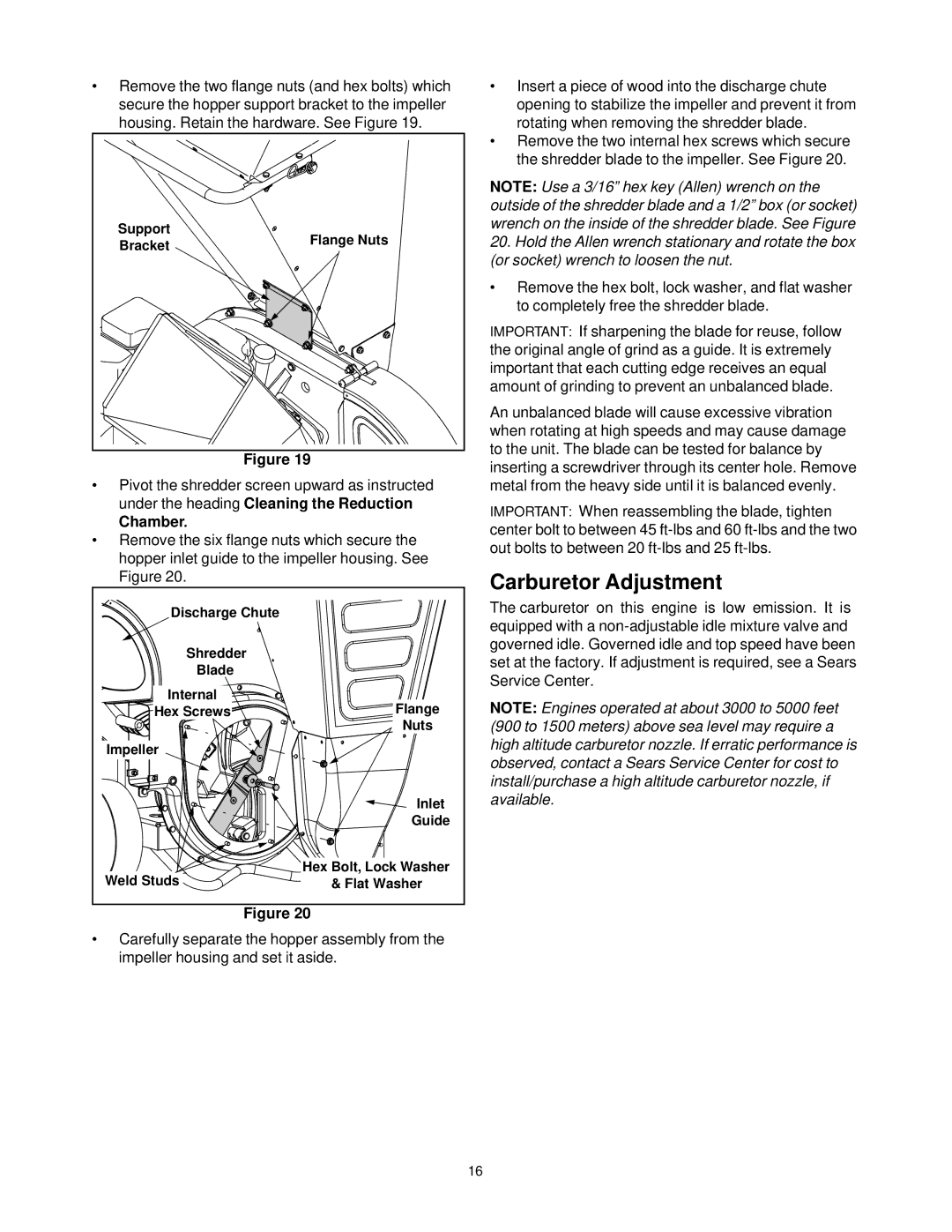

•Remove the six flange nuts which secure the hopper inlet guide to the impeller housing. See Figure 20.

Discharge Chute |

|

Shredder |

|

Blade |

|

Internal | Flange |

Hex Screws | |

| Nuts |

Impeller |

|

| Inlet |

| Guide |

Weld Studs | Hex Bolt, Lock Washer |

& Flat Washer |

Figure 20

•Carefully separate the hopper assembly from the impeller housing and set it aside.

•Insert a piece of wood into the discharge chute opening to stabilize the impeller and prevent it from rotating when removing the shredder blade.

•Remove the two internal hex screws which secure the shredder blade to the impeller. See Figure 20.

NOTE: Use a 3/16” hex key (Allen) wrench on the outside of the shredder blade and a 1/2” box (or socket) wrench on the inside of the shredder blade. See Figure

20.Hold the Allen wrench stationary and rotate the box (or socket) wrench to loosen the nut.

•Remove the hex bolt, lock washer, and flat washer to completely free the shredder blade.

IMPORTANT: If sharpening the blade for reuse, follow the original angle of grind as a guide. It is extremely important that each cutting edge receives an equal amount of grinding to prevent an unbalanced blade.

An unbalanced blade will cause excessive vibration when rotating at high speeds and may cause damage to the unit. The blade can be tested for balance by inserting a screwdriver through its center hole. Remove metal from the heavy side until it is balanced evenly.

IMPORTANT: When reassembling the blade, tighten center bolt to between 45

Carburetor Adjustment

The carburetor on this engine is low emission. It is equipped with a

NOTE: Engines operated at about 3000 to 5000 feet (900 to 1500 meters) above sea level may require a high altitude carburetor nozzle. If erratic performance is observed, contact a Sears Service Center for cost to install/purchase a high altitude carburetor nozzle, if available.

16