DRILLING

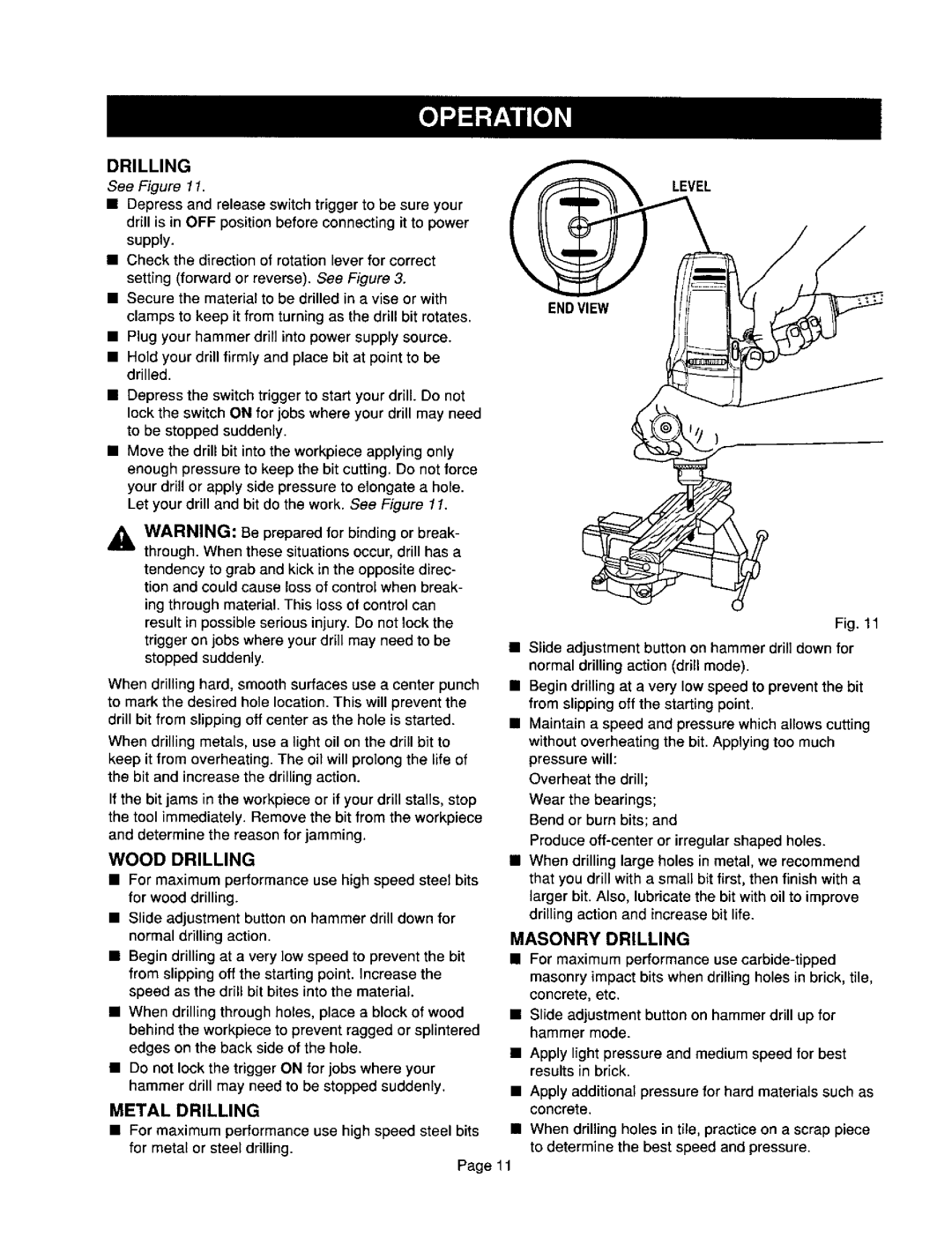

See Figure 11.

•Depress and release switch trigger to be sure your

drill is in OFF position before connecting it to power supply.

•Check the direction of rotation lever for correct setting (forward or reverse). See Figure 3.

•Secure the material to be drilled in a vise or with clamps to keep it from turning as the drill bit rotates.

•Plug your hammer drill into power supply source.

•Hold your drill firmly and place bit at point to be drilled.

•Depress the switch trigger to start your drill. Do not lock the switch ON for jobs where your drill may need to be stopped suddenly.

•Move the drill bit into the workpiece applying only enough pressure to keep the bit cutting. Do not force your drill or apply side pressure to elongate a hole. Let your drill and bit do the work. See Figure 11.

,_ WARNING: Be prepared for binding or break- through. When these situations occur, drill has a

tendency to grab and kick in the opposite direc- tion and could cause loss of control when break-

ing through material. This loss of control can result in possible serious injury. Do not lock the trigger on jobs where your drill may need to be stopped suddenly.

When drilling hard, smooth surfaces use a center punch

to mark the desired hole location. This will prevent the drill bit from slipping off center as the hole is started.

When drilling metals, use a light oil on the drill bit to keep it from overheating. The oil will prolong the life of the bit and increase the drilling action.

If the bit jams in the workpiece or if your drill stalls, stop the tool immediately. Remove the bit from the workpiece and determine the reason for jamming.

WOOD DRILLING

•For maximum performance use high speed steel bits for wood drilling.

•Slide adjustment button on hammer drill down for normal drilling action.

•Begin drilling at a very low speed to prevent the bit from slipping off the starting point. Increase the speed as the drill bit bites into the material.

•When drilling through holes, place a block of wood behind the workpiece to prevent ragged or splintered edges on the back side of the hole.

•Do not lock the trigger ON for jobs where your hammer drill may need to be stopped suddenly.

METAL DRILLING

•For maximum performance use high speed steel bits for metal or steel drilling.

LEVEL

ENDVIEW

Fig. 11

•Slide adjustment button on hammer drill down for normal drilling action (drill mode).

•Begin drilling at a very low speed to prevent the bit from slipping off the starting point.

•Maintain a speed and pressure which allows cutting without overheating the bit. Applying too much pressure will:

Overheat the drill; Wear the bearings; Bend or burn bits; and

Produce

•When drilling large holes in metal, we recommend that you drill with a small bit first, then finish with a larger bit. Also, lubricate the bit with oil to improve drilling action and increase bit life.

MASONRY DRILLING

•For maximum performance use

•Slide adjustment button on hammer drill up for hammer mode.

•Apply light pressure and medium speed for best results in brick.

•Apply additional pressure for hard materials such as concrete.

•When drilling holes in tile, practice on a scrap piece to determine the best speed and pressure.

Page 11