•Form a loop by forcing end with round holes through slotted hole opposite end.

•Place the loop over the cord and pull it tight.

•Mount the chuck key by inserting the geared end through the hole in the holder. Large keys in the larger hole, smaller keys in the small hole.

VARIABLE SPEED

See Figure 5.

Your hammer drill has a variable speed control switch that delivers higher speed with increased trigger pres- sure. Speed is controlled by the amount of switch trigger depression.

Avoid running your hammer drill at low speeds for extended periods of time. Running at low speeds under constant usage may cause your drill to become over- heated. If this occurs, cool your drill by running it without a load and at full speed.

The following guidelines may be used in determining correct speed for various applications:

•Low speed is ideal when minimum speed and power is required. For example: starting holes without center punching, driving screws, mixing paint, and drilling in ceramics.

•Medium speed is suitable for drilling hard metals, plastics, and laminates.

•High speed produces best results when maximum power is required. For example: drilling in wood, soft metals such as aluminum, brass, and copper, and when using driving accessories.

_ WARNING: Your hammer drill should never be connected to power supply when you are assem- bling parts, making adjustments, installing or removing drill bits, or when not in use. Discon- necting your drill will prevent accidental starting that could cause serious injury.

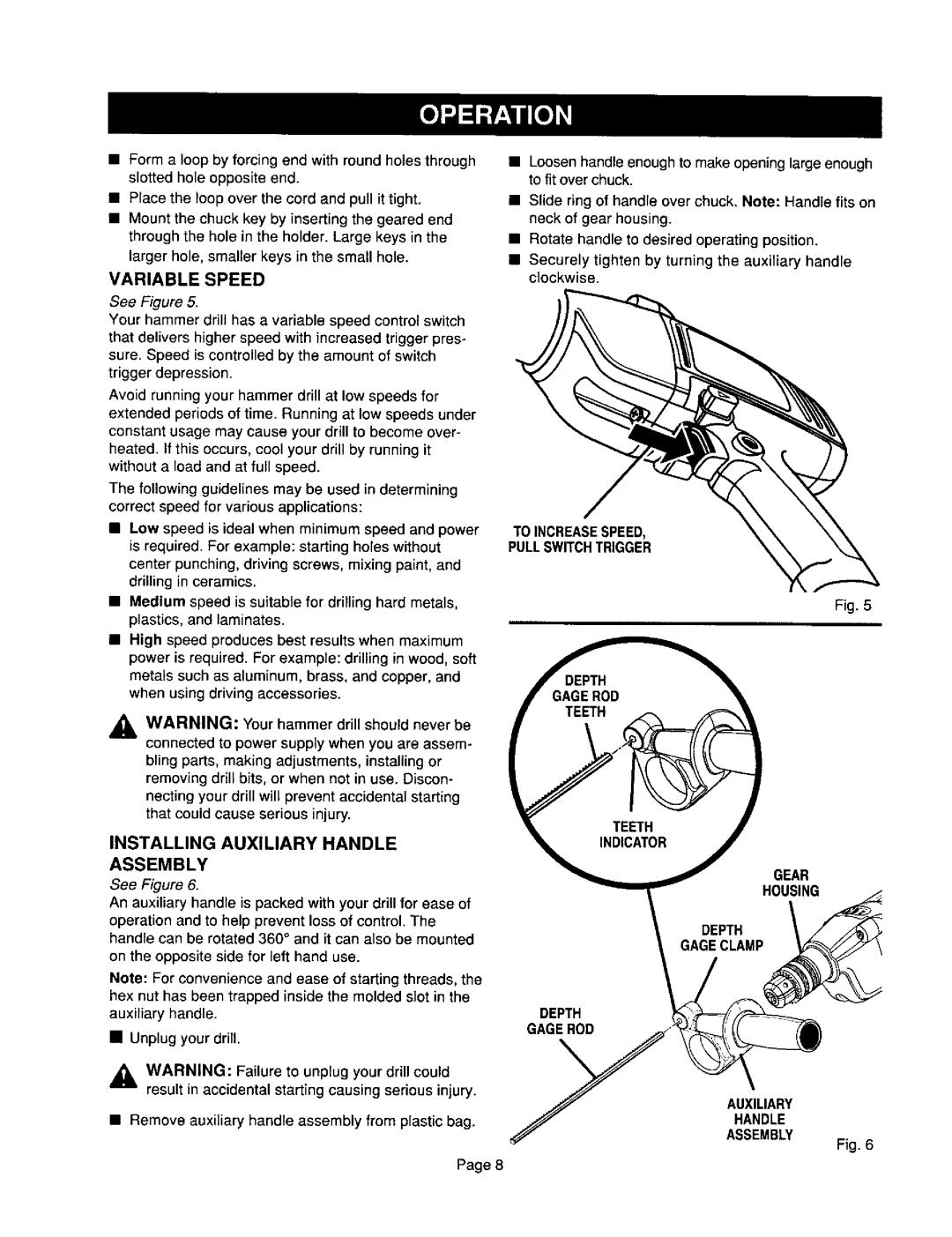

INSTALLING AUXILIARY HANDLE

ASSEMBLY

See Figure 6.

An auxiliary handle is packed with your drillfor ease of operation and to help prevent loss of control, The handle can be rotated 360 ° and it can also be mounted

on the opposite side for left hand use.

Note: For convenience and ease of starting threads, the hex nut has been trapped inside the molded slot in the

auxiliary handle.

•Unplug your drill.

,_ WARNING: Failure to unplug your drill could result in accidental starting causing serious injury.

•Remove auxiliary handle assembly from plastic bag.

•Loosen handle enough to make opening large enough to fit over chuck.

•Slide ring of handle over chuck. Note: Handle fits on neck of gear housing.

•Rotate handle to desired operating position.

•Securely tighten by turning the auxiliary handle clockwise.

TO INCREASE SPEED,

PULL SWITCH TRIGGER

Fig. 5

GAGE ROD

TEETH

TEETH

INDICATOR

GEAR

HOUSING

DEPTH

GAGECLAMP

DEPTH

GAGEROD

AUXILIARY

HANDLE

ASSEMBLY

Fig. 6

Page 8