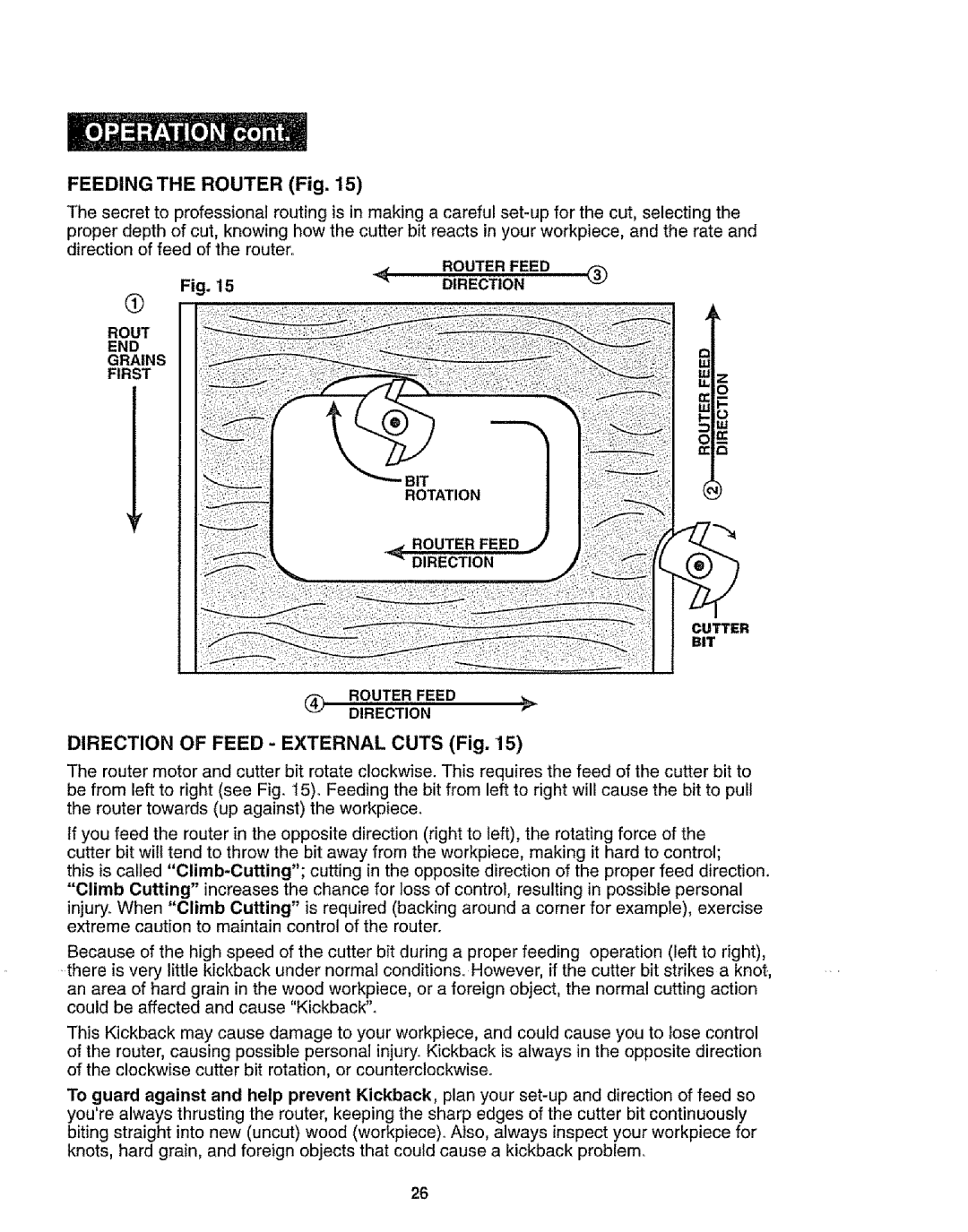

FEEDING THE ROUTER (Fig. 15)

The secret to professional routing is in making a careful

proper depth of cut, knowing how the cutter bit reacts in your workpiece, and the rate and direction of feed of the router°

.< | ROUTEREED ® |

Fig. 15 | DIRECTION |

Q |

|

ROUT |

|

END |

|

GRAINS |

|

FIRST |

|

CUTTER

BIT

(_ ROUT,ER FEED

DIRECTION

DIRECTION OF FEED - EXTERNAL CUTS (Fig. 15)

The router motor and cutter bit rotate clockwise. This requires the feed of the cutter bit to be from left to right (see Fig. 15). Feeding the bit from left to right will cause the bit to pull the router towards (up against) the workpiece.

tf you feed the router in the opposite direction (right to left), the rotating force of the cutter bit will tend to throw the bit away from the workpiece, making it hard to control;

this is called

injury. When "Climb Cutting" is required (backing around a corner for example), exercise extreme caution to maintain control of the router.

Because of the high speed of the cutter bit during a proper feeding operation (left to right), there is very little kickback under normal conditions. However, if the cutter bit strikes a knot,

an area of hard grain in the wood workpiece, or a foreign object, the normal cutting action could be affected and cause "Kickback".

This Kickback may cause damage to your workpiece, and could cause you to lose control of the router, causing possible personal injury. Kickback is always in the opposite direction of the clockwise cutter bit rotation, or counterclockwise.

To guard against and help prevent Kickback, plan your

26