Support bearing (FIG. S)

6.Loosen the bearing hex socket screw (7) with the hex wrench.

7.Move the blade support bearing shaft (8) in or out until the support bearing (9) is 1/64" behind the saw blade.

8.Tighten the bearing hex socket screw.

FIG. S

9

8

BASIC SAW OPERATIONS

ON / OFF SWITCH (FIG. U)

The keyed switch is intended to prevent unauthorized use of the band saw.

1.To turn the band saw ON insert the yellow key (1) into the key slot (2) in the center of the switch.

2.Push the key firmly into the slot, then push switch to the ON position to start the band saw.

3.To turn the band saw OFF push the switch to the down position.

4.Remove the yellow switch key, when the saw has come to a complete stop, by gently pulling it outward.

Remove the switch key whenever the saw is not in use. Place it in a safe place and out of reach of children.

To avoid twisting the blade, do not turn sharp corners, saw around corners.

A band saw is basically a

capable of doing intricate inside cutting as can be done with a scroll saw.

It is also used for straight line operations such as crosscutting, ripping, mitering, beveling, compound cutting, and resawing.

To avoid blade breakage, fire or other damage or injury, NEVER use this band saw to cut ferrous metals.

CUTTING CURVES

When cutting curves, carefully turn the workpiece so the blade follows without twisting. If the curve is so sharp that you repeatedly back up and cut new kerr, use a narrower blade, or a blade with more set (teeth further apart). When a blade has more set, the workpiece turns easier but the cut is rougher.

When changing a cut, do not withdraw the workpiece from the blade. The blade may get drawn off the wheels. To

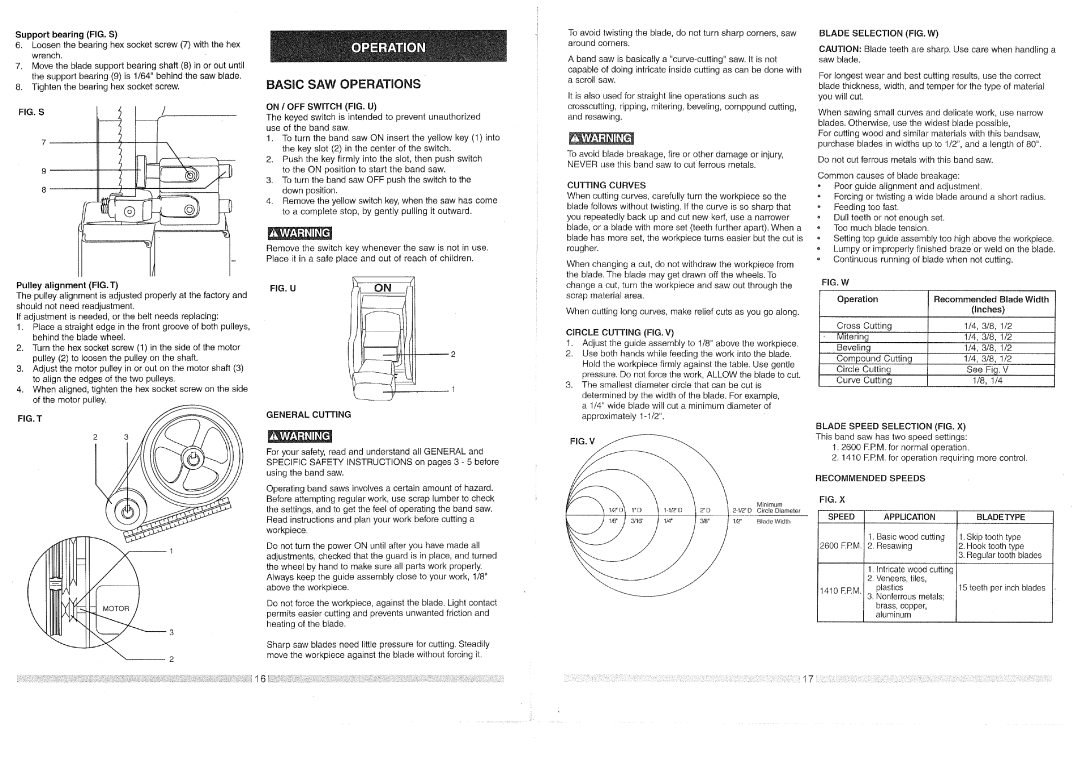

BLADE SELECTION (FIG. W)

CAUTION: Blade teeth are sharp. Use care when handling a saw blade.

For longest wear and best cutting results, use the correct blade thickness, width, and temper for the type of material you will cut.

When sawing small curves and delicate work, use narrow blades. Otherwise, use the widest blade possible,

For cutting wood and similar materials with this bandsaw, purchase blades in widths up to 1/2", and a length of 80".

Do not cut ferrous metals with this band saw.

Common causes of blade breakage:

•Poor guide alignment and adjustment.

oForcing or twisting a wide blade around a short radius.

• Feeding too fast.

Dull teeth or not enough set.

Too much blade tension.

oSetting top guide assembly too high .above the workpiece. - Lumpy or improperly finished braze or weld on the blade.

Continuous running of blade when not cutting.

Pulley alignment (FIG.T)

The pulley alignment is adjusted properly at the factory and should not need readjustment.

If adjustment is needed, or the belt needs replacing:

1.Place a straight edge in the front groove of both pulleys, behind the blade wheel

2.Turn the hex socket screw (1) in the side of the motor pulley (2) to loosen the pulley on the shaft.

3.Adjust the motor pulley in or out on the motor shaft (3) to align the edges of the two pulleys.

4.When aligned, tighten the hex socket screw on the side of the motor pulley.

FIG. T

FIG. U

l ON

GENERAL CUTTING

For your safety, read and understand all GENERAL and SPECIFIC SAFETY INSTRUCTIONS on pages 3 - 5 before

change a cut, turn the workpiece and saw out through the scrap material area.

When cutting long curves, make relief cuts as you go along.

CIRCLE CUTTING (FIG. V)

1.Adjust the guide assembly to 1/8" above the workpiece.

2.Use both hands while feeding the work into the blade. Hold the workpiece firmly against the table. Use gentle pressure. Do not force the work, ALLOW the blade to cut.

3.The smallest diameter circle that can be cut is

determined by the width of the blade. For example, a 1/4" wide blade will cut a minimum diameter of

approximately

FIG. V

FIG. W |

|

|

|

|

Operation | Recommended | Blade Width | ||

|

| (Inches) | ||

Cross | Cutting | 1/4, 3/8, | 1/2 | |

Mitering | 1/4, | 3/8, | 1/2 | |

Beveling | 1/4, | 3/8, | 1/2 | |

Compound Cutting | 1/4, 3/8, | 1/2 | ||

Circle | Cutting | See | Fig. V | |

Curve | Cutting | 1/8, 1/4 | ||

BLADE SPEED SELECTION (FIG. X)

This band saw has two speed settings:

1.2600 RRM. for normal operation.

2.1410 RRM. for operation requiring more control.

using the band saw.

Operating band saws involves a certain amount of hazard. Before attempting regular work, use scrap lumber to check the settings, and to get the feel of operating the band saw.

RECOMMENDED SPEEDS

FIG. X

Minimum

Read instructions and plan your work before cutting a workpiece.

1/2" Blade Width

SPEED APPLICATION BLADETYPE

1. Basic wood cutting 1.Skip tooth type

Do not turn the power ON until after you have made all adjustments, checked that the guard is in place, and turned the wheel by hand to make sure all parts work properly. Always keep the guide assembly close to your work, 1/8" above the workpiece.

Do not force the workpiece, against the blade. Light contact permits easier cutting and prevents unwanted friction and heating of the blade.

Sharp saw biades need little pressure for cutting. Steadily move the workpiece against the blade without forcing it.

2600 KRM. 2. Resawing2. Hook tooth type

3. Regular tooth blades

1.Intricatewood cutting

2.Veneers, tiles,

1410 RRM. plastics15 teeth per inch blades

3. Nonferrous metals;

brass, copper, aluminum

16 | : | 17 |