Check track for tension (Pull up g | ,at center) |

LUBRICATION - EVERY 25 HOURS

•Lubricate Disc Drive Plate every 25 hours and at the end of the season and/or before

storage.

To Lubricate:

•Remove bottom panel. See second figure on page 20.

•Position speed selector lever in first gear.

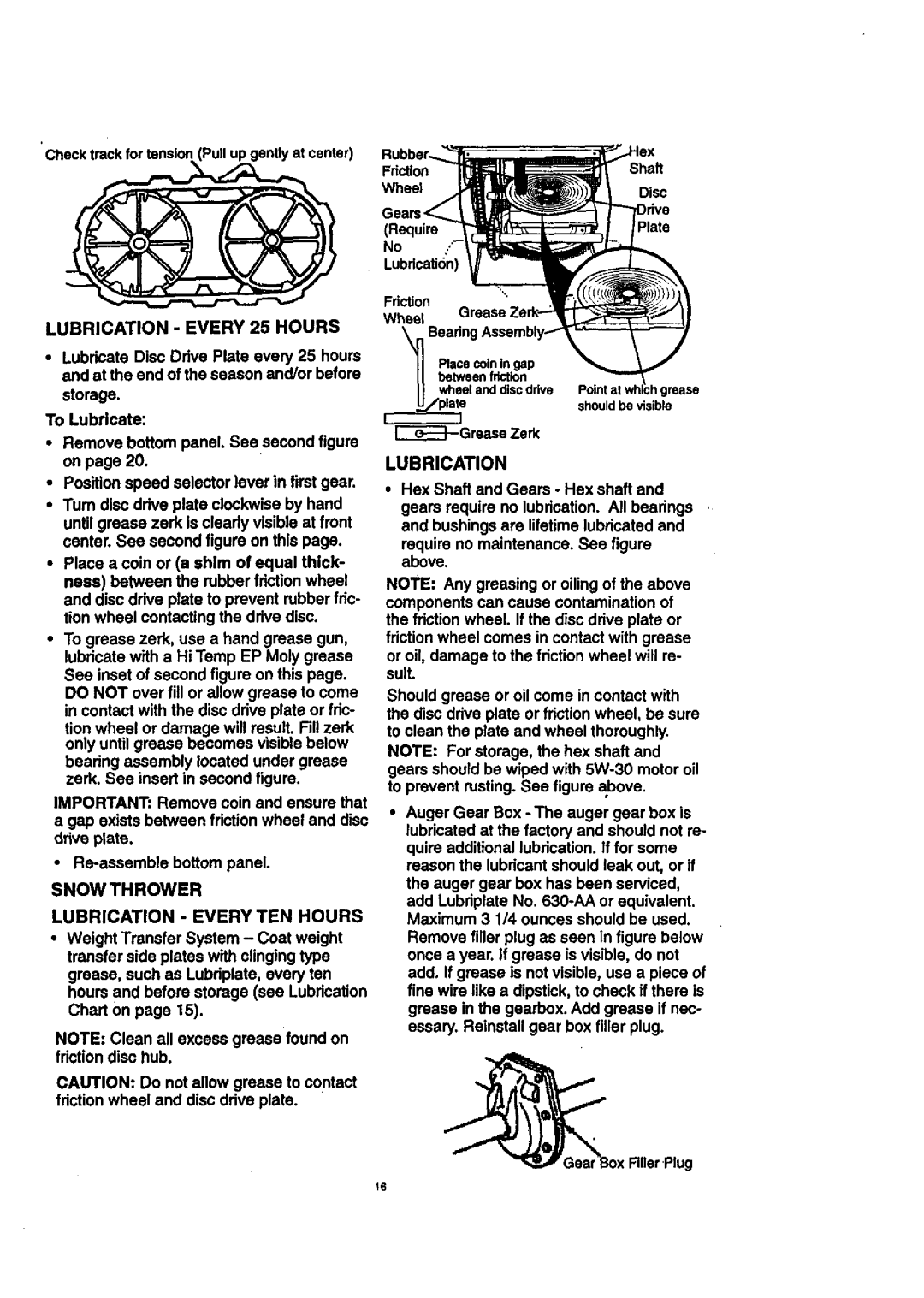

•Turn disc drive plate clockwise by hand until grease zerk is clearly visible at front center. See second figure on this page.

•Place a coin or (a shim of equal thick- ness) between the rubber friction wheel and disc drive plate to prevent rubber fric- tion wheel contacting the drive disc.

•To grease zerk, use a hand grease gun, lubricate with a Hi Temp EP Moly grease See inset of second figure on this page.

DO NOT over fill or allow grease to come in contact with the disc drive plate or fric- tion wheel or damage will result. Fill zerk only until grease becomes visible below bearing assembly located under grease zerk. See insert in second figure.

IMPORTANT: Remove coin and ensure that

a gap exists between friction wheel and disc drive plate.

•

SNOW THROWER

LUBRICATION - EVERY TEN HOURS

•Weight Transfer System - Coat weight transfer side plates with clinging type grease, such as Lubriplate, every ten hours and before storage (see Lubrication Chart on page 15).

NOTE: Clean all excess grease found on friction disc hub.

CAUTION: Do not allow grease to contact friction wheel and disc drive plate.

Fdctlon |

|

| Shaft |

Wheel |

|

| Disc |

|

|

| |

(Require |

| Plate | |

|

| ||

No |

|

|

|

Lubdcation) |

|

| |

Friction |

|

|

|

Wheel |

|

|

|

Beadng |

|

| |

| Placecoiningap |

| |

| betweenfriction |

| |

| wheelanddiscddve | grease | |

[ | plate |

| shouldbe visible |

I | Zerk |

| |

| |||

LUBRICATION

•Hex Shaft and Gears - Hex shaft and

gears require no lubrication. All bearings and bushings are lifetime lubricated and

require no maintenance. See figure above.

NOTE: Any greasing or oiling of the above components can cause contamination of the friction wheel. If the disc drive plate or friction wheel comes in contact with grease or oil, damage to the friction wheel will re- suit.

Should grease or oil come in contact with the disc drive plate or friction wheel, be sure to clean the plate and wheel thoroughly. NOTE: For storage, the hex shaft and gears should be wiped with

•Auger Gear Box - The auger gear box is lubricated at the factory and should not re- quire additional lubrication. If for some reason the lubricant should leak out, or if the auger gear box has been serviced, add Lubriplate No.

Remove filler plug as seen in figure below once a year. If grease is visible, do not add. If grease is not visible, use a piece of fine wire like a dipstick, to check if there is grease in the gearbox. Add grease if nec- essary. Reinstall gear box filler plug.

g

16