917.254611 specifications

The Craftsman 917.254611 is a highly regarded lawn tractor that offers homeowners an efficient and reliable solution for maintaining their lawns. With a user-friendly design and robust features, it stands out as a practical choice for both novice and seasoned garden enthusiasts.One of the main features of the Craftsman 917.254611 is its powerful engine. The tractor is equipped with a 17.5 HP Briggs & Stratton engine, providing ample power for tackling various yard tasks. This engine is not only strong but also designed for reliability, ensuring that users can depend on it to start easily and perform consistently over time.

The cutting deck is another significant aspect of the Craftsman 917.254611. It boasts a 42-inch deck, which is ideal for maneuvering around obstacles and achieving clean cuts over medium to large-sized lawns. The deck height can be easily adjusted, allowing for six different cutting heights ranging from 1.5 to 4 inches. This flexibility ensures that users can adapt to different grass types and preferences.

In terms of technology and ease of use, the Craftsman 917.254611 incorporates an automatic transmission system. This feature simplifies the driving experience, allowing users to enjoy smooth and seamless operation without the hassle of manual shifting. The comfortable seat and ergonomically designed controls enhance user comfort and reduce fatigue during extended mowing sessions.

Another noteworthy characteristic is the tractor's maneuverability. With a tight turning radius, the Craftsman 917.254611 allows users to navigate around trees, flower beds, and other obstacles effortlessly. This capability is particularly valuable for homeowners with intricate landscaping or tight spaces in their yards.

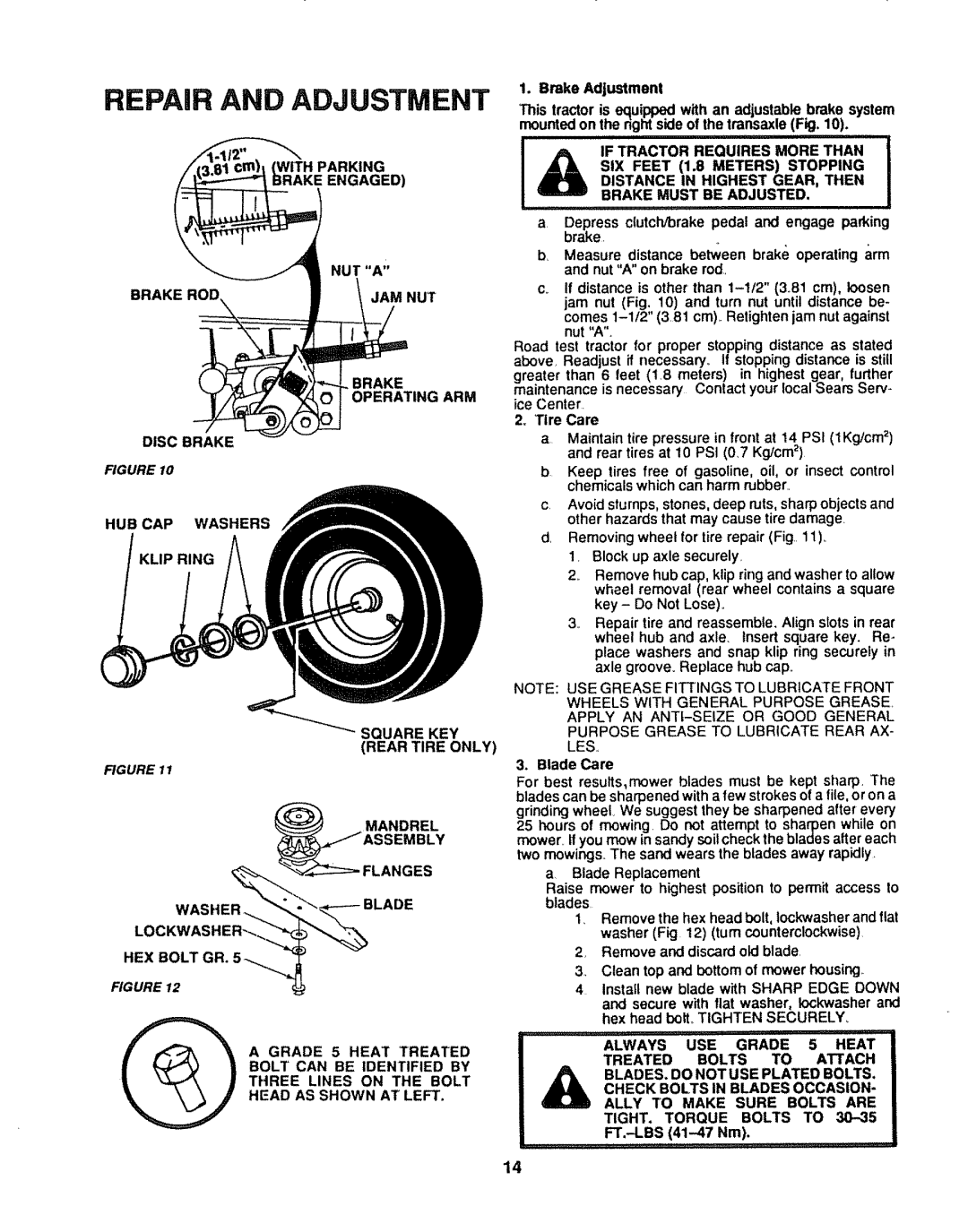

Maintenance considerations are also addressed with this model. The Craftsman 917.254611 features easy-access components, making routine checks and servicing straightforward for users. The removable deck further aids in cleaning and maintenance tasks, ensuring that the tractor remains in peak condition over its lifespan.

In conclusion, the Craftsman 917.254611 combines power, versatility, and ease of use, making it an exceptional lawn tractor for homeowners. Its strong engine, adjustable cutting deck, and user-friendly features position it as a reliable choice for those seeking an efficient way to maintain their outdoor spaces, providing a tidy and well-kept lawn with minimal effort.