•Coat terminals with grease or petroleum jelly.

•Reinstall battery (See =CONNECT BAT-

TERY" in the Assembly section of this

manual).

V-BELTS

Check

TRANSAXLE COOLING

Keep transaxle free from

and chaff which can restrict cooling.

ENGINE LUBRICATION

Only use high quality detergent oil rated with API service classification SF, SG, or SH. Select the oil'sSAE viscosity grade according to your expected operating tem- perature.

Change the oil alter every 50 hours of operation or at least once a year if the tractor is not used for 50 hours in one

year.

Check the crankcase oil level before start- ing the engine and after each eight (8) hours of operation. Tighten oil fill cap/dip- stick securely each time you check the oil level.

SAE VISCOSITY GRADES

T()_HANGE _N_'E O_

Determinetemperaturerangeexpected beforeoilchange. All oilmustmeet API serviceclassificationSF, SG, or SH.

•Be sure tractoris on level surface.

•Oil willdrain morefreely when warm.

•Catch oilin a suitablecontainer.

•Remove oilfillcap/dipstick.Be careful not to allowdirtto enter the engine when changingoil

•Remove drainplug.

•After oil has drainedcompletely,replace oil drain plugand tightensecurely.

•Refillenginewith o=3throughoilfill dip- sticktube. Pourslowly. Do not overfill. For approximatecapacitysee =PROD-

UCT SPECIFICATIONS"on page 3 of this.ro,_, al..;... _

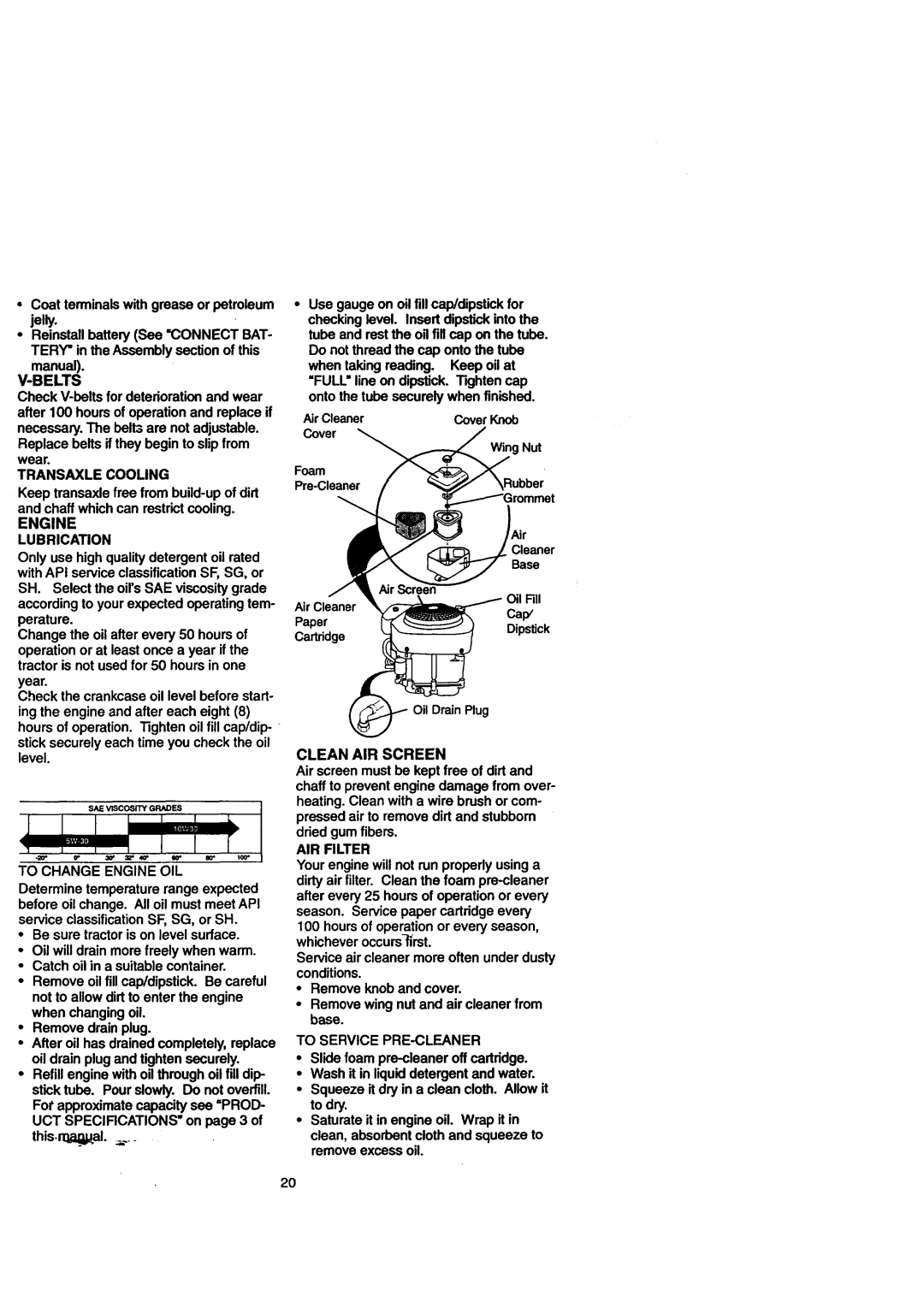

•Use gauge on oil till cap/dipstick for checking level. Insert dipstick into the tube and rest the oUfill cap on the tube. Do not thread the cap onto the tube

when taking reading. Keep oil at =FULL= line on dipstick. Tighten cap onto the tube securely when finished.

Air Cleaner | CoverKnob |

Cover |

|

| Wing Nut |

Foam |

|

| |

| Air |

| Cleaner |

| Base |

| Oil Fill |

Air Cleaner | Cap/ |

Paper | Dipstick |

Cartridge |

|

Oil Drain Plug

CLEAN AIR SCREEN

Air screen must be kept free of dirt and chaff to prevent engine damage from over- heating. Clean with a wire brush or com- pressed air to remove dirt and stubborn dried gum fibers.

AIR FILTER

Your engine will not run properly using a dirty air filter. Clean the foam

100hours of operation or every season, whichever

Service air cleaner more often under dusty conditions.

•Remove knob and cover.

•Remove wing nut and air cleaner from base.

TO SERVICE PRE-CLEANER

•Slidefoam pre_leaner offcartridge.

•Wash it in liquiddetergentand water.

•Squeeze itdry in a cleancloth. Allow it to dry.

•Saturateit in engineoil. Wrap itin clean,absorbentclothand squeezeto removeexcessoil.

2O