917.28947, 917.289470 specifications

The Craftsman 917.28947 and 917.289470 are robust lawn tractors designed for homeowners seeking durability, performance, and comfort in their yard care equipment. These models stand out in the Craftsman line due to their exceptional features, advanced technologies, and user-friendly characteristics.At the core of both models is a powerful engine, typically a 19 HP or higher, ready to tackle various mowing conditions. The engine is combined with a smooth-running automatic transmission that facilitates easy operation, allowing the driver to focus on the task without worrying about shifting gears. This feature makes mowing large lawns or navigating through obstacles much simpler.

One of the most notable characteristics of the Craftsman 917.28947 and 917.289470 is their 42-inch cutting deck. This size is ideal for providing a quick yet efficient cut, capable of maneuvering in tighter spaces while still covering more ground than smaller decks. The cutting height can be easily adjusted to meet the needs of different types of grass and preferred lawn styles. This adaptability is part of what makes these models particularly appealing to a diverse range of users.

Incorporating advanced technologies, these lawn tractors often feature an ergonomic design, including a plush seat with back support that provides comfort during prolonged use. The easy-to-read dashboard displays critical information such as fuel level, speed, and battery status, allowing users to monitor their operation effectively.

Additionally, both models come equipped with essential safety features such as a safety switch that prevents the engine from starting when the operator is not seated. This attention to safety ensures peace of mind during operation, especially for those who may have children or pets around while mowing.

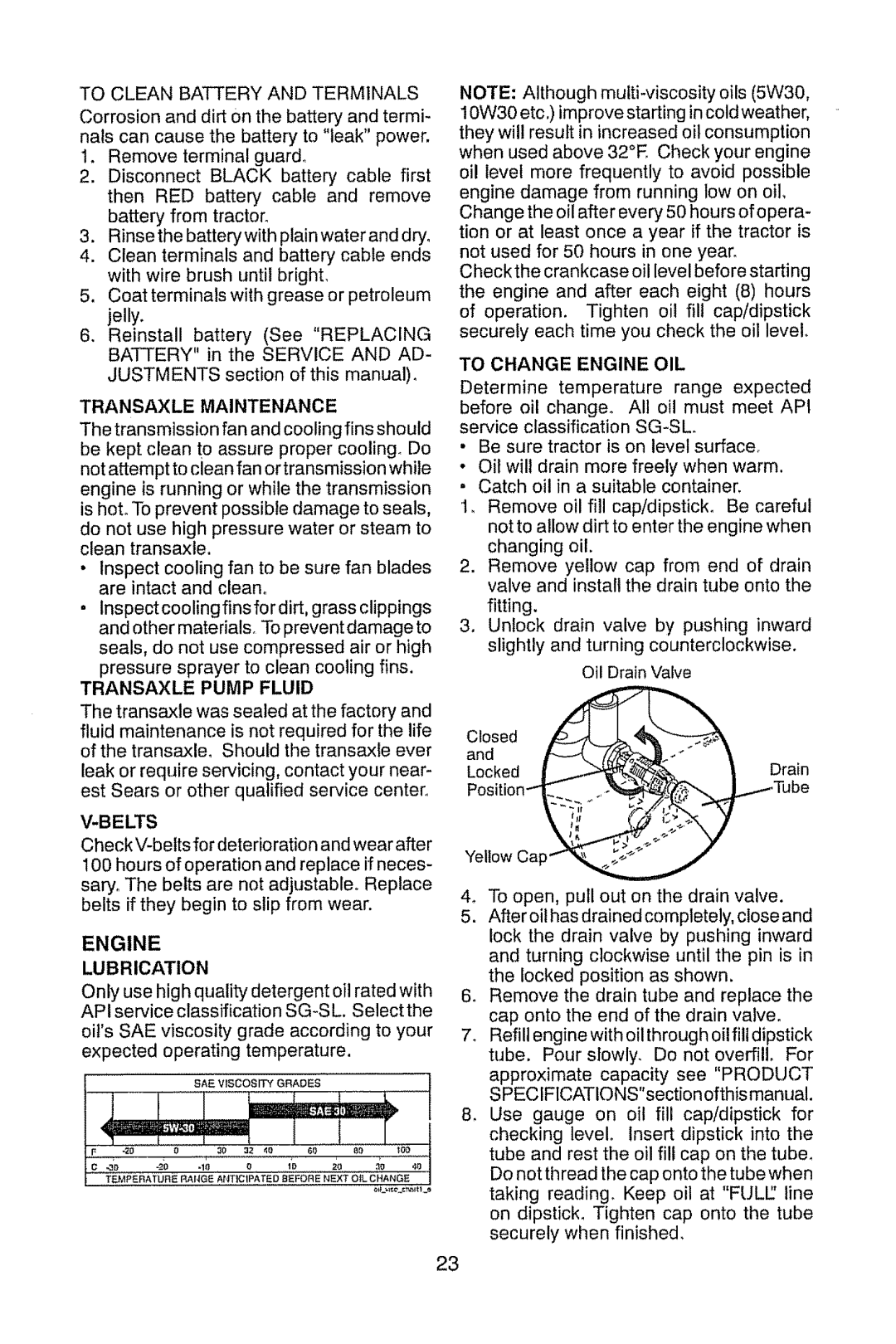

In terms of maintenance, the Craftsman 917.28947 and 917.289470 include features designed to make care manageable. The accessible design allows for easy cleaning and part replacement when necessary, ensuring that the tractors remain in top condition throughout their lifespan.

Overall, the Craftsman 917.28947 and 917.289470 represent a great combination of power, efficiency, and comfort, making them excellent choices for homeowners looking to maintain their lawns with ease and reliability. Whether tackling a small yard or a larger landscape, these lawn tractors are equipped to deliver effective performance season after season.