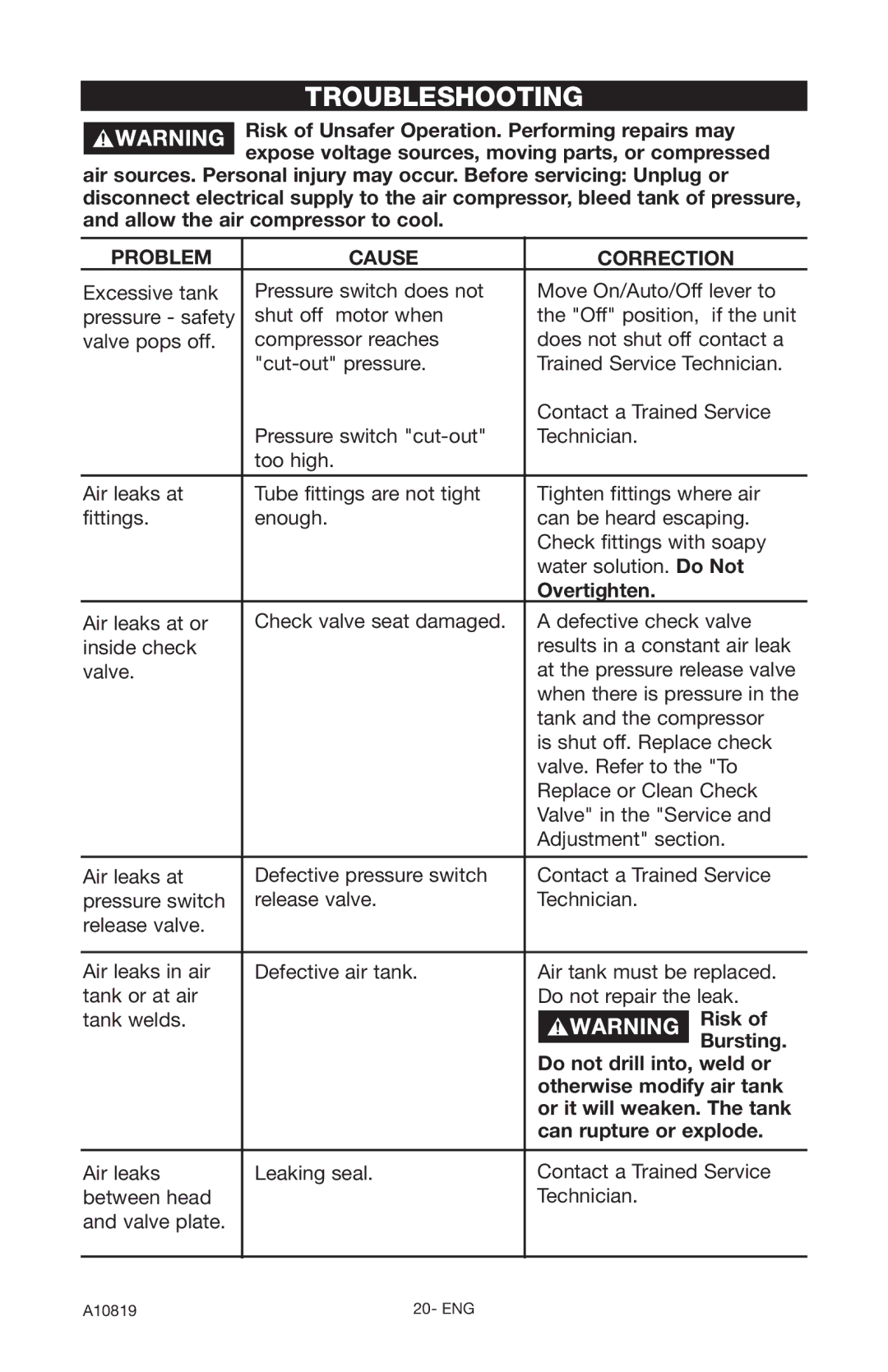

TROUBLESHOOTING

Risk of Unsafer Operation. Performing repairs may expose voltage sources, moving parts, or compressed

air sources. Personal injury may occur. Before servicing: Unplug or disconnect electrical supply to the air compressor, bleed tank of pressure, and allow the air compressor to cool.

PROBLEM | CAUSE | CORRECTION |

Excessive tank | Pressure switch does not | Move On/Auto/Off lever to |

pressure - safety | shut off motor when | the "Off" position, if the unit |

valve pops off. | compressor reaches | does not shut off contact a |

| Trained Service Technician. | |

|

| Contact a Trained Service |

| Pressure switch | Technician. |

| too high. |

|

|

|

|

Air leaks at | Tube fittings are not tight | Tighten fittings where air |

fittings. | enough. | can be heard escaping. |

|

| Check fittings with soapy |

|

| water solution. Do Not |

|

| Overtighten. |

Air leaks at or | Check valve seat damaged. | A defective check valve |

inside check |

| results in a constant air leak |

valve. |

| at the pressure release valve |

|

| when there is pressure in the |

|

| tank and the compressor |

|

| is shut off. Replace check |

|

| valve. Refer to the "To |

|

| Replace or Clean Check |

|

| Valve" in the "Service and |

|

| Adjustment" section. |

|

|

|

Air leaks at | Defective pressure switch | Contact a Trained Service |

pressure switch | release valve. | Technician. |

release valve. |

|

|

Air leaks in air | Defective air tank. | Air tank must be replaced. |

tank or at air |

| Do not repair the leak. |

tank welds. |

| Risk of |

|

| Bursting. |

|

| Do not drill into, weld or |

|

| otherwise modify air tank |

|

| or it will weaken. The tank |

|

| can rupture or explode. |

|

|

|

Air leaks | Leaking seal. | Contact a Trained Service |

between head |

| Technician. |

and valve plate. |

|

|

|

|

|

A10819 | 20- ENG |