6)Permitted Terminals for Vertical Venting -

•Vent Option 5 - A straight termination is installed in the end of the vent pipe. Vent manufacturer part numbers for these screens are shown in Table 7.5. The air inlet terminal consists of a 180 degree elbow (or two 90 degree elbows) with a rodent screen as shown in Figure 7.10.

•Vent Option 6 - Use Crown PN 230532 with the appropriate flashing (Table 7.4b)

7)Vertical Vent Terminal Locations (Vent Options 5,6) - Observe the following limitations on the location of all vertical vent terminals (see Figures 7.10, 7.11):

•The top of the vent pipe must be at least 2 feet above any object located within 10 feet.

•For Vent Option #5, the vertical distance between top of the vent and air inlet terminal openings must be at least 12”.

•The bottom of the air inlet terminal must be at least 12” above the normal snow accumulation that can be expected on the roof. The terminal used in Vent Option #6 has a fixed distance above the storm collar of 19”. If a greater distance is needed to provide the clearance above the snow line, build a chase on the roof and mount the vertical terminal on top of the chase.

•For Vent Option #5, the air intake terminal must be located on the roof and must be no further than 24” horizontally from the exhaust pipe.

8)Wall thimbles – Wall thimbles are required where single wall vent pipe passes through combustible walls with less than the required clearance shown in Table 4.2 or as required by local codes. Stainless vent manufacturer’s wall thimble part numbers are shown in Table 7.5. Note that concentric vent has a “zero” clearance to combustibles and therefore does not require the use of wall thimbles.

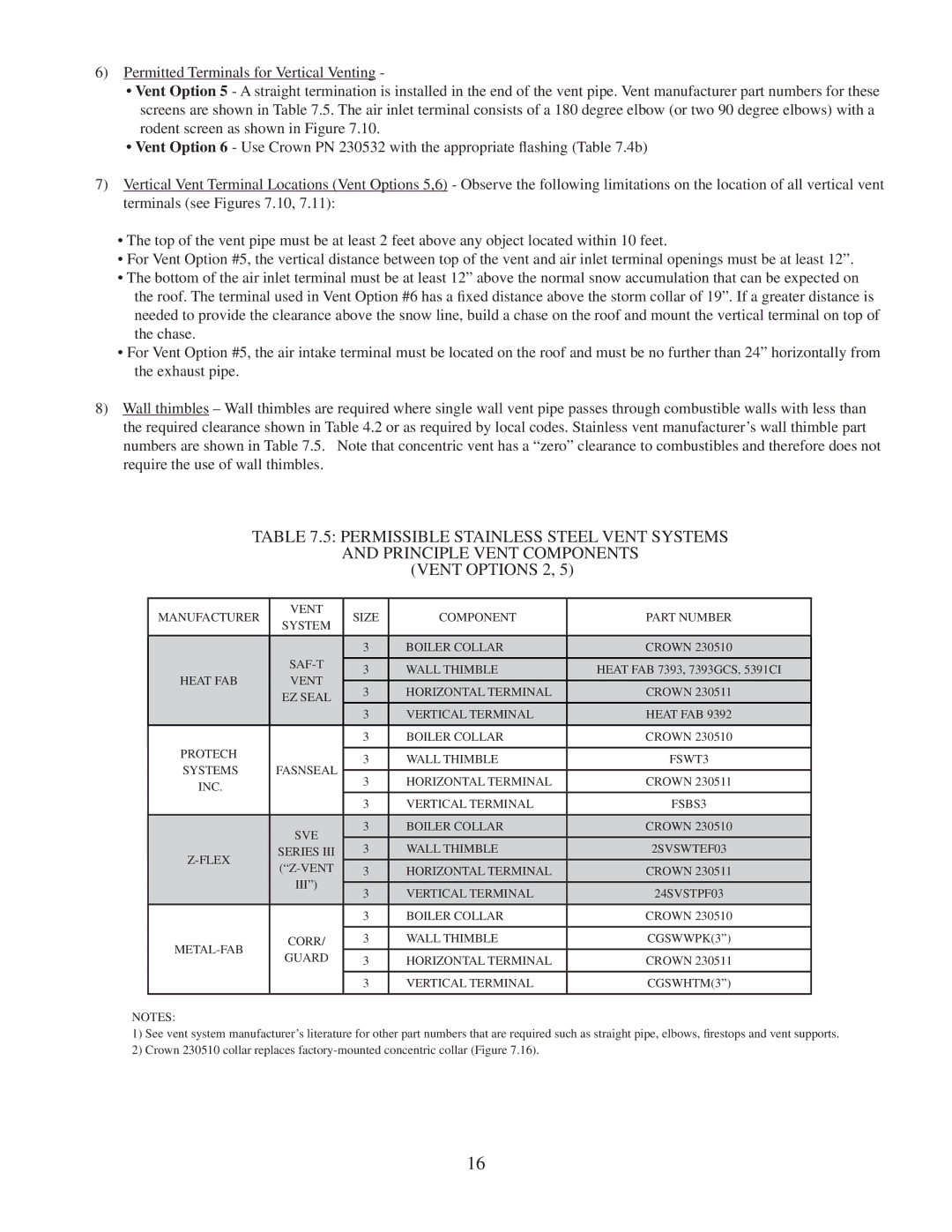

TABLE 7.5: PERMISSIBLE STAINLESS STEEL VENT SYSTEMS

AND PRINCIPLE VENT COMPONENTS

(VENT OPTIONS 2, 5)

MANUFACTURER | VENT | SIZE | COMPONENT | PART NUMBER | |

SYSTEM | |||||

|

|

|

| ||

|

| 3 | BOILER COLLAR | CROWN 230510 | |

|

|

|

| ||

| 3 | WALL THIMBLE | HEAT FAB 7393, 7393GCS, 5391CI | ||

HEAT FAB | VENT | ||||

|

|

| |||

3 | HORIZONTAL TERMINAL | CROWN 230511 | |||

| EZ SEAL | ||||

|

|

|

| ||

|

| 3 | VERTICAL TERMINAL | HEAT FAB 9392 | |

|

|

|

|

| |

|

| 3 | BOILER COLLAR | CROWN 230510 | |

PROTECH |

|

|

|

| |

| 3 | WALL THIMBLE | FSWT3 | ||

SYSTEMS | FASNSEAL | ||||

|

|

| |||

3 | HORIZONTAL TERMINAL | CROWN 230511 | |||

INC. |

| ||||

|

|

|

| ||

|

| 3 | VERTICAL TERMINAL | FSBS3 | |

|

|

|

|

| |

| SVE | 3 | BOILER COLLAR | CROWN 230510 | |

|

|

|

| ||

| 3 | WALL THIMBLE | 2SVSWTEF03 | ||

SERIES III | |||||

3 | HORIZONTAL TERMINAL | CROWN 230511 | |||

| |||||

| III”) |

|

|

| |

| 3 | VERTICAL TERMINAL | 24SVSTPF03 | ||

|

| ||||

|

|

|

|

| |

|

| 3 | BOILER COLLAR | CROWN 230510 | |

|

|

|

|

| |

CORR/ | 3 | WALL THIMBLE | CGSWWPK(3”) | ||

GUARD | 3 | HORIZONTAL TERMINAL | CROWN 230511 | ||

| |||||

|

|

|

|

| |

|

| 3 | VERTICAL TERMINAL | CGSWHTM(3”) | |

|

|

|

|

|

NOTES:

1)See vent system manufacturer’s literature for other part numbers that are required such as straight pipe, elbows, firestops and vent supports.

2)Crown 230510 collar replaces

16