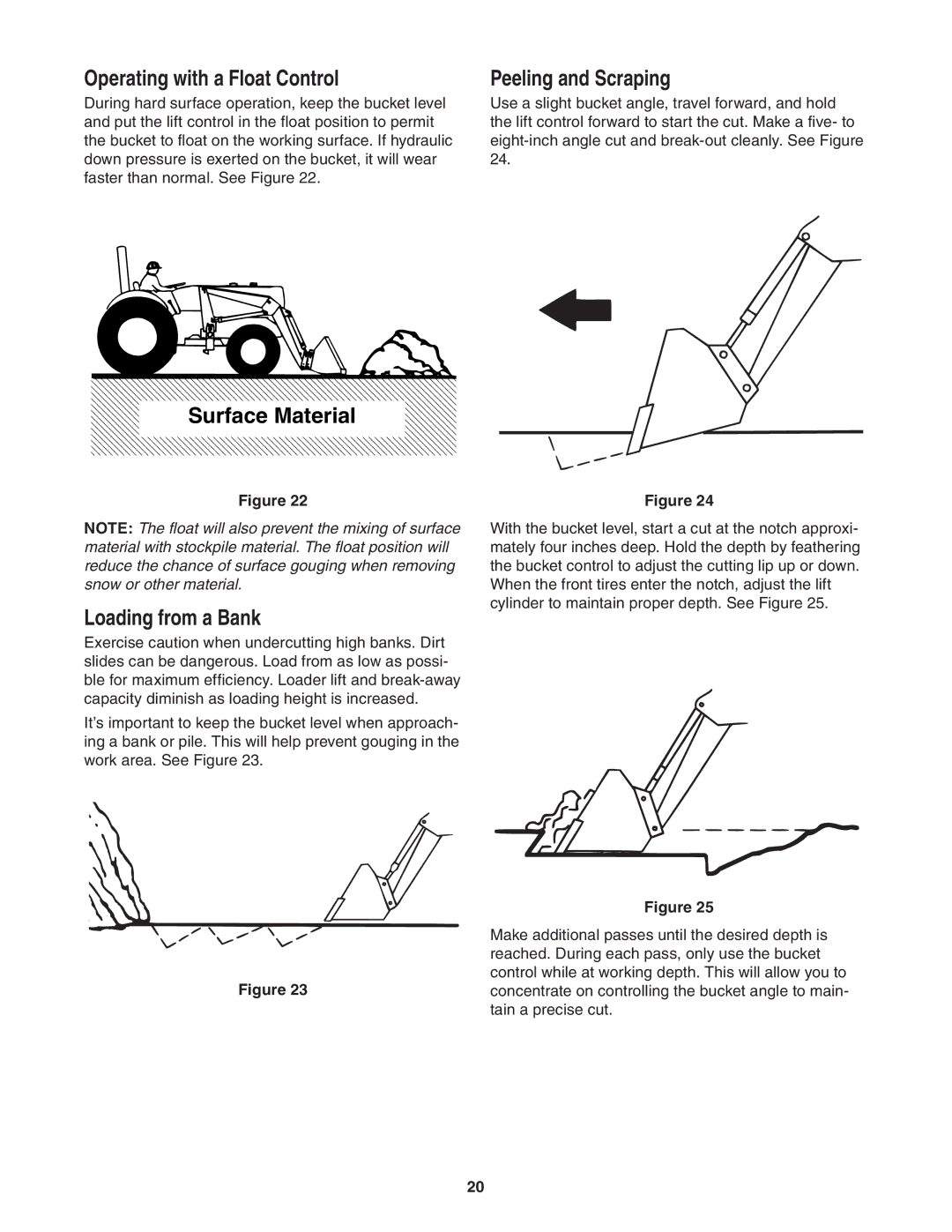

Operating with a Float Control

During hard surface operation, keep the bucket level and put the lift control in the float position to permit the bucket to float on the working surface. If hydraulic down pressure is exerted on the bucket, it will wear faster than normal. See Figure 22.

Surface Material

Peeling and Scraping

Use a slight bucket angle, travel forward, and hold the lift control forward to start the cut. Make a five- to

Figure 22

NOTE: The float will also prevent the mixing of surface material with stockpile material. The float position will reduce the chance of surface gouging when removing snow or other material.

Loading from a Bank

Exercise caution when undercutting high banks. Dirt slides can be dangerous. Load from as low as possi- ble for maximum efficiency. Loader lift and

It’s important to keep the bucket level when approach- ing a bank or pile. This will help prevent gouging in the work area. See Figure 23.

Figure 24

With the bucket level, start a cut at the notch approxi- mately four inches deep. Hold the depth by feathering the bucket control to adjust the cutting lip up or down. When the front tires enter the notch, adjust the lift cylinder to maintain proper depth. See Figure 25.

| Figure 25 |

| Make additional passes until the desired depth is |

| reached. During each pass, only use the bucket |

Figure 23 | control while at working depth. This will allow you to |

concentrate on controlling the bucket angle to main- | |

| tain a precise cut. |

20