FACEPLATE

![]() To reduce the risk of injury, tighten all screws and levers securely when adjusting any part of the lathe.

To reduce the risk of injury, tighten all screws and levers securely when adjusting any part of the lathe.

![]() To reduce the risk of injury, when using the included 3" (76 mm) faceplate (B) Fig. 2, do not mount pieces larger than 6" (152 mm) in diameter and up to 6" (152 mm) in length. For mounting larger pieces, be sure to use an appropriately sized faceplate.

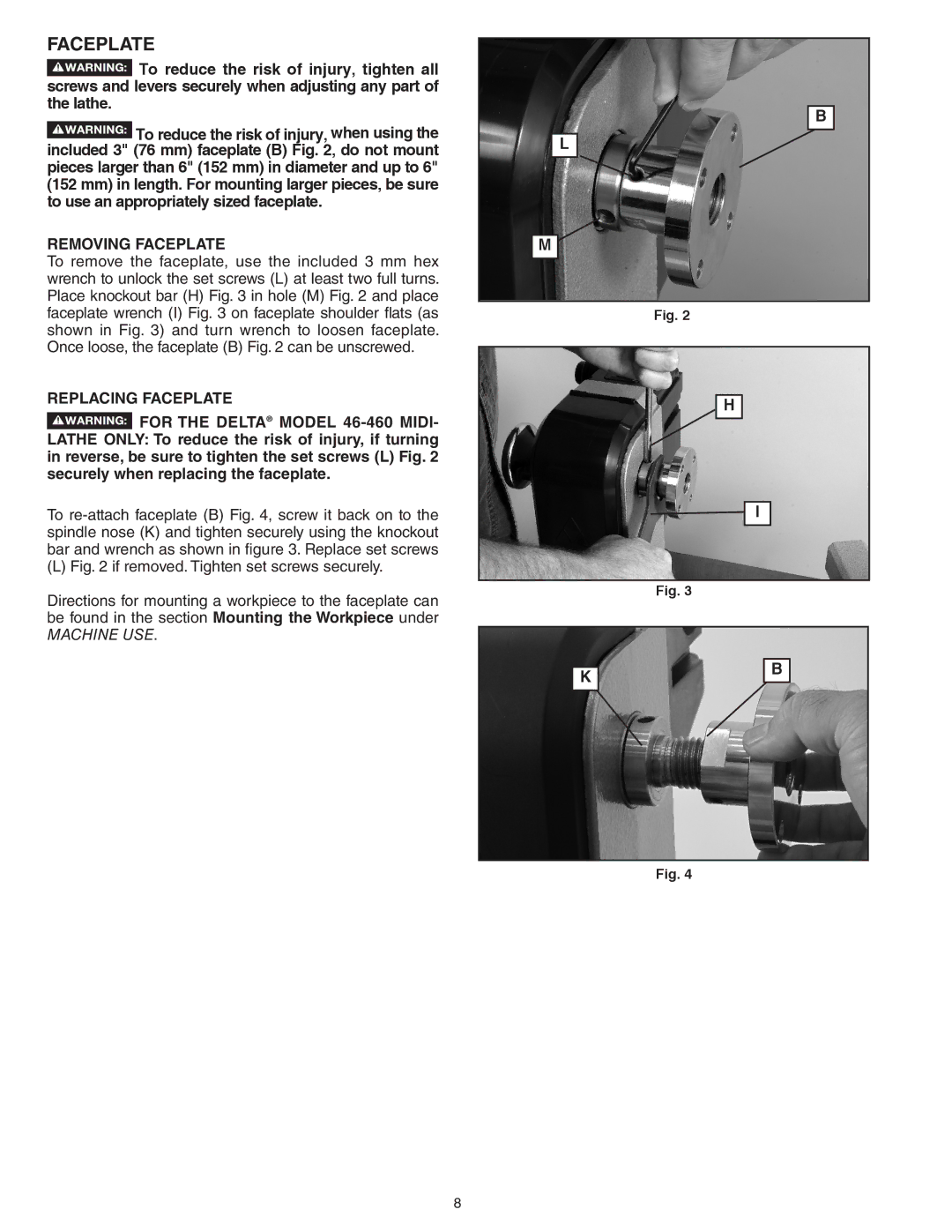

To reduce the risk of injury, when using the included 3" (76 mm) faceplate (B) Fig. 2, do not mount pieces larger than 6" (152 mm) in diameter and up to 6" (152 mm) in length. For mounting larger pieces, be sure to use an appropriately sized faceplate.

REMOVING FACEPLATE

To remove the faceplate, use the included 3 mm hex wrench to unlock the set screws (L) at least two full turns. Place knockout bar (H) Fig. 3 in hole (M) Fig. 2 and place faceplate wrench (I) Fig. 3 on faceplate shoulder flats (as shown in Fig. 3) and turn wrench to loosen faceplate. Once loose, the faceplate (B) Fig. 2 can be unscrewed.

REPLACING FACEPLATE

![]() FOR THE DELTA® MODEL

FOR THE DELTA® MODEL

To

(L) Fig. 2 if removed. Tighten set screws securely.

Directions for mounting a workpiece to the faceplate can be found in the section Mounting the Workpiece under

MACHINE USE.

B

L

M

Fig. 2

H

I

Fig. 3

|

| B |

K |

| |

|

|

|

Fig. 4

8