ACTIVATING THE SPINDLE

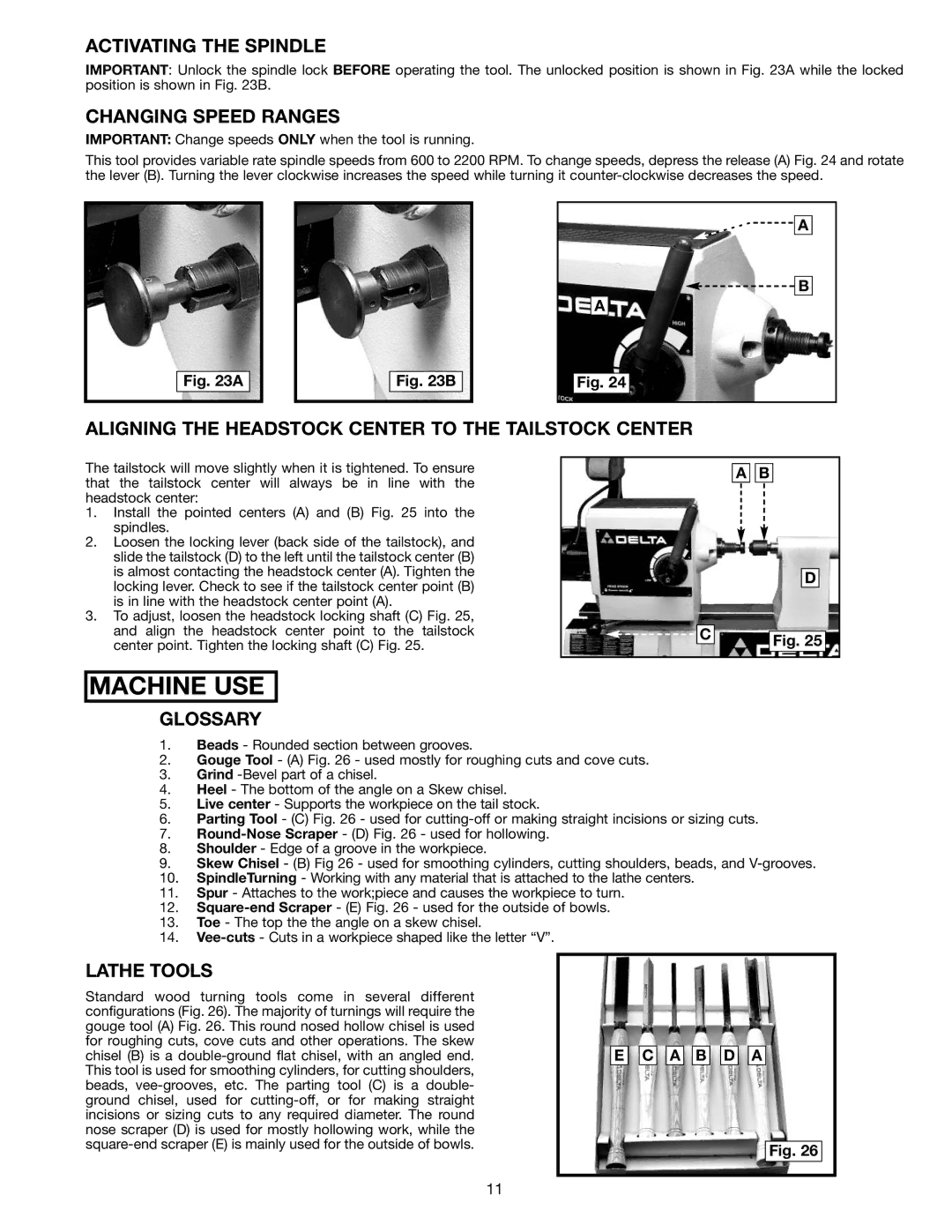

IMPORTANT: Unlock the spindle lock BEFORE operating the tool. The unlocked position is shown in Fig. 23A while the locked position is shown in Fig. 23B.

CHANGING SPEED RANGES

IMPORTANT: Change speeds ONLY when the tool is running.

This tool provides variable rate spindle speeds from 600 to 2200 RPM. To change speeds, depress the release (A) Fig. 24 and rotate the lever (B). Turning the lever clockwise increases the speed while turning it

Fig. 23A

Fig. 23B

![]()

![]()

![]() A

A

![]()

![]()

![]() B

B

A

Fig. 24

ALIGNING THE HEADSTOCK CENTER TO THE TAILSTOCK CENTER

The tailstock will move slightly when it is tightened. To ensure that the tailstock center will always be in line with the headstock center:

1.Install the pointed centers (A) and (B) Fig. 25 into the spindles.

2.Loosen the locking lever (back side of the tailstock), and slide the tailstock (D) to the left until the tailstock center (B) is almost contacting the headstock center (A). Tighten the locking lever. Check to see if the tailstock center point (B) is in line with the headstock center point (A).

3.To adjust, loosen the headstock locking shaft (C) Fig. 25, and align the headstock center point to the tailstock center point. Tighten the locking shaft (C) Fig. 25.

![]()

![]()

![]() C

C

A ![]()

![]() B

B

D

Fig. 25

MACHINE USE

GLOSSARY

1.Beads - Rounded section between grooves.

2.Gouge Tool - (A) Fig. 26 - used mostly for roughing cuts and cove cuts.

3.Grind

4.Heel - The bottom of the angle on a Skew chisel.

5.Live center - Supports the workpiece on the tail stock.

6.Parting Tool - (C) Fig. 26 - used for

7.

8.Shoulder - Edge of a groove in the workpiece.

9.Skew Chisel - (B) Fig 26 - used for smoothing cylinders, cutting shoulders, beads, and

10.SpindleTurning - Working with any material that is attached to the lathe centers.

11.Spur - Attaches to the work;piece and causes the workpiece to turn.

12.

13.Toe - The top the the angle on a skew chisel.

14.

LATHE TOOLS

Standard wood turning tools come in several different configurations (Fig. 26). The majority of turnings will require the gouge tool (A) Fig. 26. This round nosed hollow chisel is used for roughing cuts, cove cuts and other operations. The skew chisel (B) is a

E ![]()

![]() C

C ![]()

![]() A

A ![]()

![]() B

B ![]()

![]() D

D ![]()

![]() A

A

Fig. 26

11