8.Fig. 69 illustrates the rough cutting of the inside of a bowl.

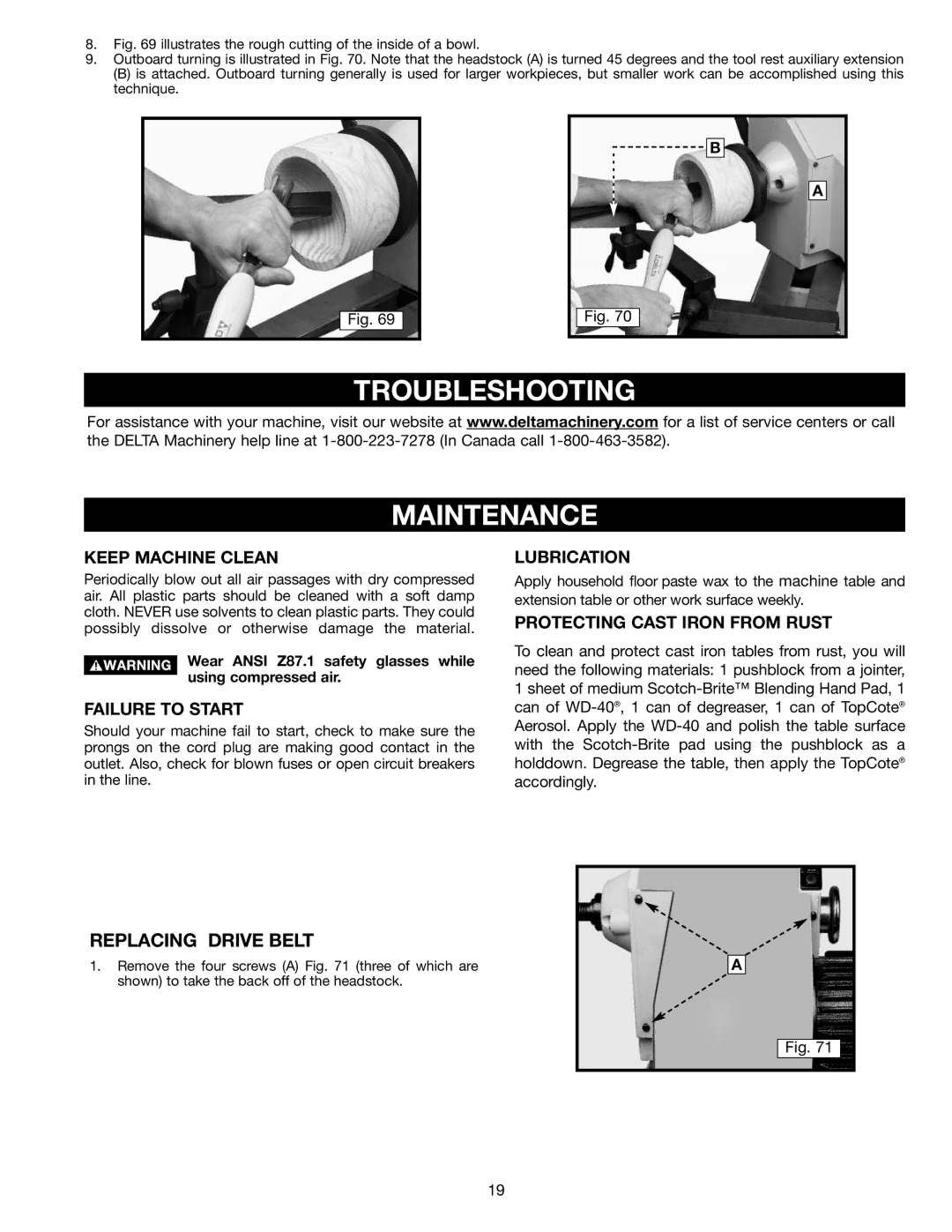

9.Outboard turning is illustrated in Fig. 70. Note that the headstock (A) is turned 45 degrees and the tool rest auxiliary extension

(B)is attached. Outboard turning generally is used for larger workpieces, but smaller work can be accomplished using this technique.

![]()

![]() B

B

A

Fig. 69

Fig. 70

TROUBLESHOOTING

For assistance with your machine, visit our website at www.deltamachinery.com for a list of service centers or call the DELTA Machinery help line at

MAINTENANCE

KEEP MACHINE CLEAN

Periodically blow out all air passages with dry compressed air. All plastic parts should be cleaned with a soft damp cloth. NEVER use solvents to clean plastic parts. They could possibly dissolve or otherwise damage the material.

Wear ANSI Z87.1 safety glasses while using compressed air.

FAILURE TO START

Should your machine fail to start, check to make sure the prongs on the cord plug are making good contact in the outlet. Also, check for blown fuses or open circuit breakers in the line.

LUBRICATION

Apply household floor paste wax to the machine table and extension table or other work surface weekly.

PROTECTING CAST IRON FROM RUST

To clean and protect cast iron tables from rust, you will need the following materials: 1 pushblock from a jointer, 1 sheet of medium

REPLACING DRIVE BELT

1.Remove the four screws (A) Fig. 71 (three of which are shown) to take the back off of the headstock.

A

Fig. 71

19