CUTTING ALUMINUM

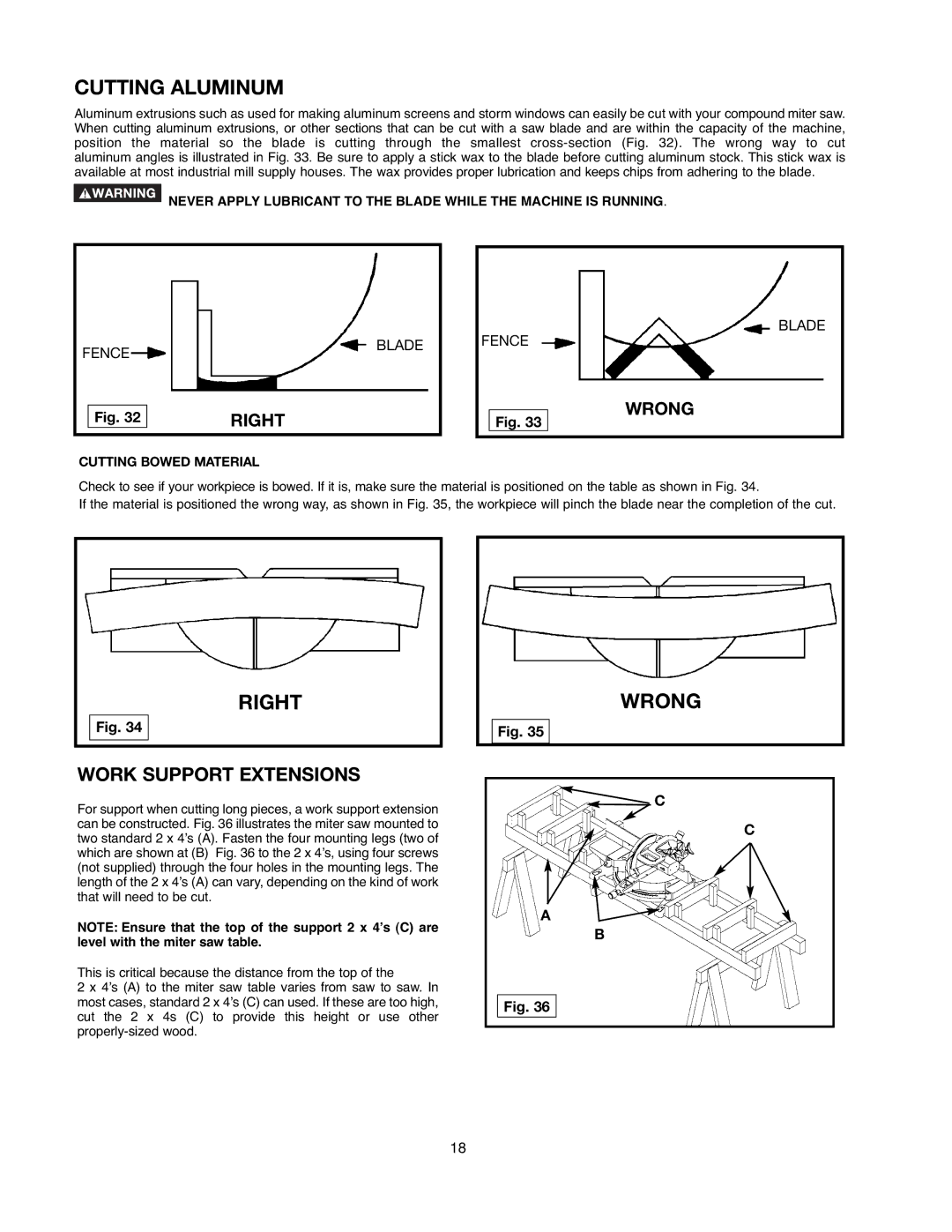

Aluminum extrusions such as used for making aluminum screens and storm windows can easily be cut with your compound miter saw. When cutting aluminum extrusions, or other sections that can be cut with a saw blade and are within the capacity of the machine, position the material so the blade is cutting through the smallest

![]() NEVER APPLY LUBRICANT TO THE BLADE WHILE THE MACHINE IS RUNNING.

NEVER APPLY LUBRICANT TO THE BLADE WHILE THE MACHINE IS RUNNING.

FENCE

Fig. 32

BLADE

RIGHT

FENCE

Fig. 33

BLADE

WRONG

CUTTING BOWED MATERIAL

Check to see if your workpiece is bowed. If it is, make sure the material is positioned on the table as shown in Fig. 34.

If the material is positioned the wrong way, as shown in Fig. 35, the workpiece will pinch the blade near the completion of the cut.

RIGHT

Fig. 34

WORK SUPPORT EXTENSIONS

For support when cutting long pieces, a work support extension can be constructed. Fig. 36 illustrates the miter saw mounted to two standard 2 x 4’s (A). Fasten the four mounting legs (two of which are shown at (B) Fig. 36 to the 2 x 4’s, using four screws (not supplied) through the four holes in the mounting legs. The length of the 2 x 4’s (A) can vary, depending on the kind of work that will need to be cut.

NOTE: Ensure that the top of the support 2 x 4’s (C) are level with the miter saw table.

This is critical because the distance from the top of the

2 x 4’s (A) to the miter saw table varies from saw to saw. In most cases, standard 2 x 4’s (C) can used. If these are too high, cut the 2 x 4s (C) to provide this height or use other

WRONG

Fig. 35

![]() C

C

C

A![]()

B

Fig. 36

18