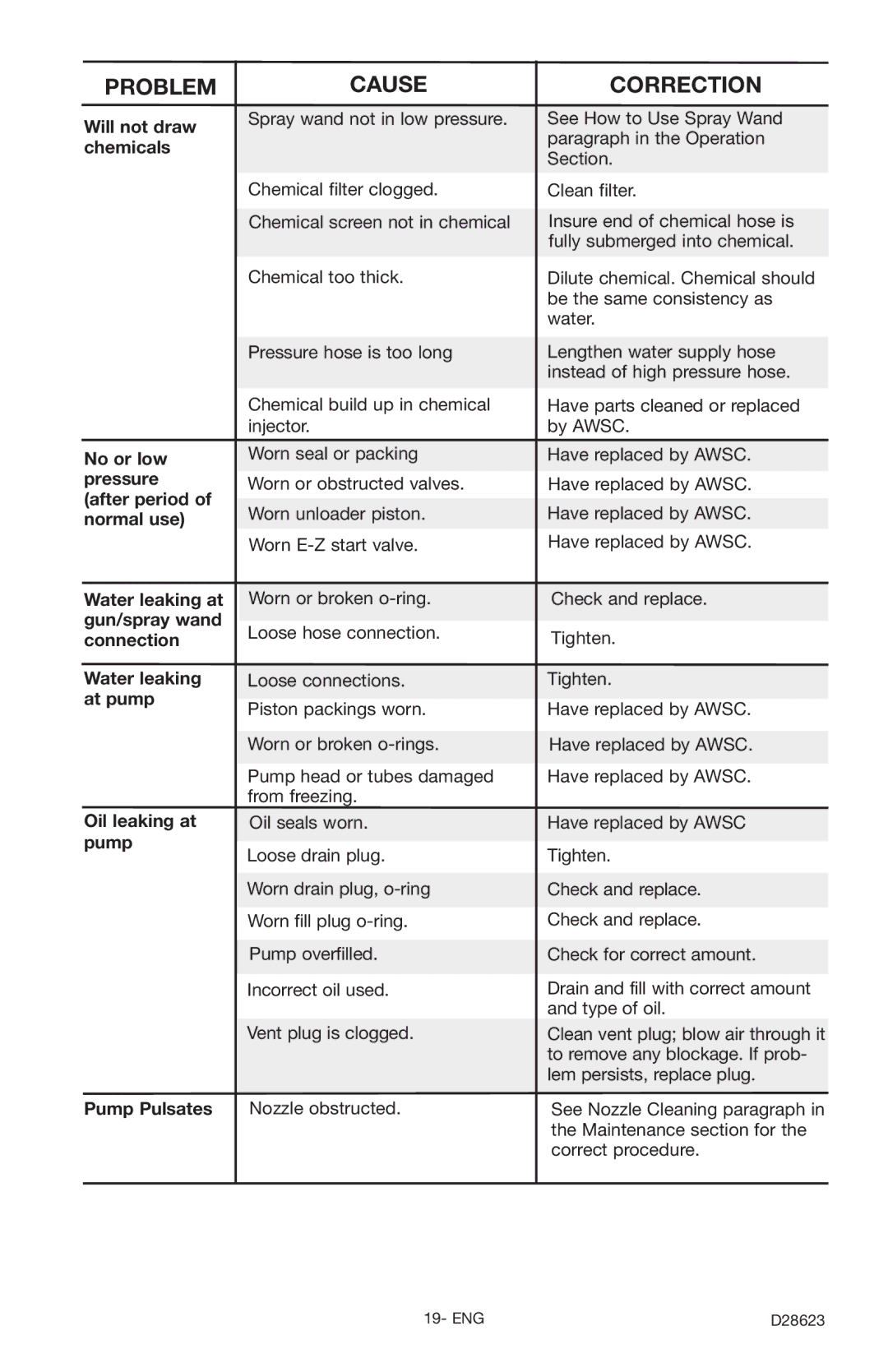

PROBLEM | CAUSE | CORRECTION | |

|

|

| |

Will not draw | Spray wand not in low pressure. | See How to Use Spray Wand | |

| paragraph in the Operation | ||

chemicals |

| ||

| Section. | ||

|

| ||

| Chemical filter clogged. | Clean filter. | |

|

|

| |

| Chemical screen not in chemical | Insure end of chemical hose is | |

|

| fully submerged into chemical. | |

| Chemical too thick. | Dilute chemical. Chemical should | |

|

| be the same consistency as | |

|

| water. | |

|

|

| |

| Pressure hose is too long | Lengthen water supply hose | |

|

| instead of high pressure hose. | |

| Chemical build up in chemical | Have parts cleaned or replaced | |

| injector. | by AWSC. | |

|

|

| |

No or low | Worn seal or packing | Have replaced by AWSC. | |

pressure | Worn or obstructed valves. | Have replaced by AWSC. | |

(after period of |

|

| |

Worn unloader piston. | Have replaced by AWSC. | ||

normal use) | |||

| Worn | Have replaced by AWSC. | |

|

|

| |

Water leaking at | Worn or broken | Check and replace. | |

gun/spray wand |

|

| |

Loose hose connection. | Tighten. | ||

connection | |||

Water leaking |

|

| |

Loose connections. | Tighten. | ||

at pump |

|

| |

Piston packings worn. | Have replaced by AWSC. | ||

| |||

|

|

| |

| Worn or broken | Have replaced by AWSC. | |

|

|

| |

| Pump head or tubes damaged | Have replaced by AWSC. | |

| from freezing. |

| |

Oil leaking at | Oil seals worn. | Have replaced by AWSC | |

pump |

|

| |

Loose drain plug. | Tighten. | ||

| |||

|

|

| |

| Worn drain plug, | Check and replace. | |

|

|

| |

| Worn fill plug | Check and replace. | |

|

|

| |

| Pump overfilled. | Check for correct amount. | |

|

|

| |

| Incorrect oil used. | Drain and fill with correct amount | |

|

| and type of oil. | |

| Vent plug is clogged. | Clean vent plug; blow air through it | |

|

| to remove any blockage. If prob- | |

|

| lem persists, replace plug. | |

|

|

| |

Pump Pulsates | Nozzle obstructed. | See Nozzle Cleaning paragraph in | |

|

| the Maintenance section for the | |

|

| correct procedure. | |

|

|

|

19- ENG | D28623 |