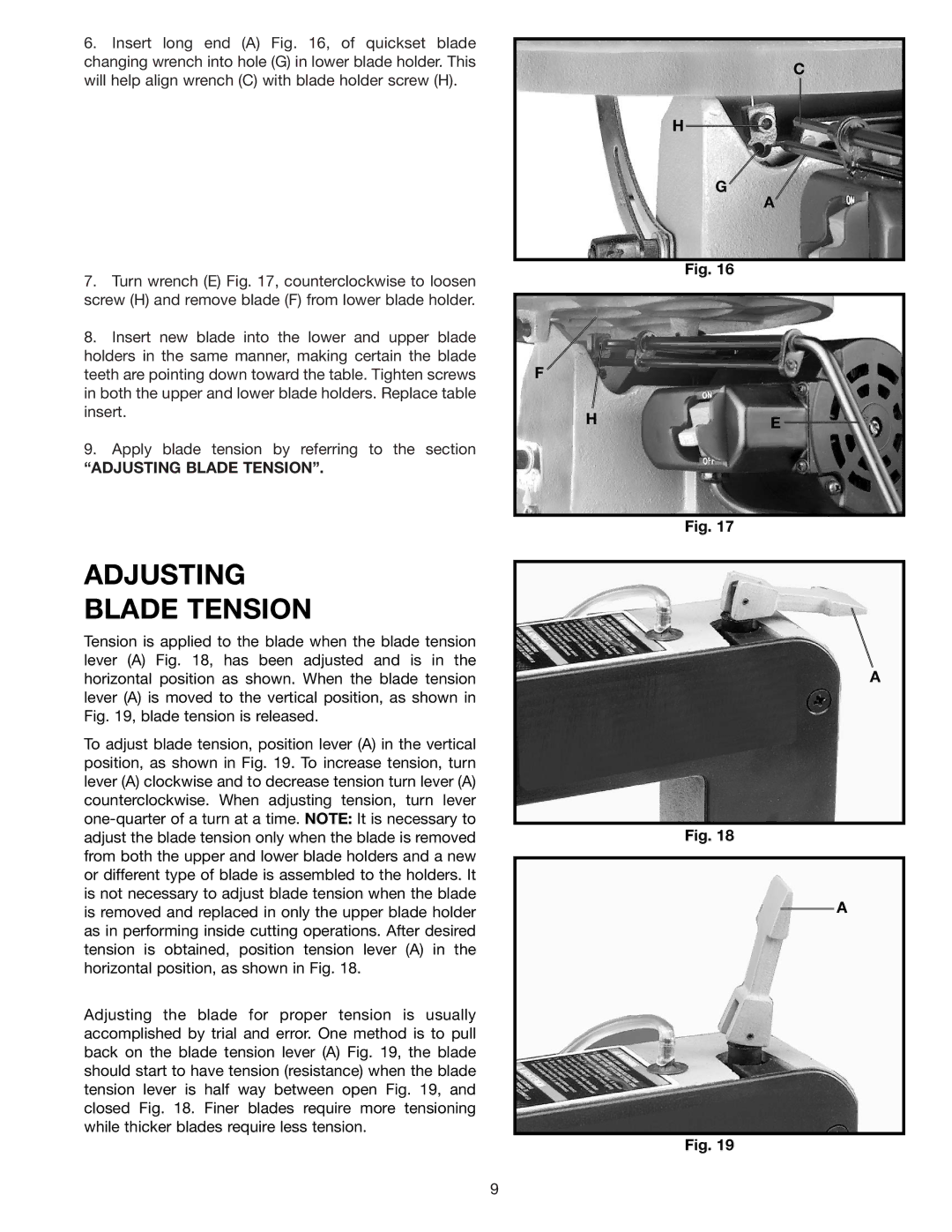

6.Insert long end (A) Fig. 16, of quickset blade changing wrench into hole (G) in lower blade holder. This will help align wrench (C) with blade holder screw (H).

7.Turn wrench (E) Fig. 17, counterclockwise to loosen screw (H) and remove blade (F) from lower blade holder.

8.Insert new blade into the lower and upper blade holders in the same manner, making certain the blade teeth are pointing down toward the table. Tighten screws in both the upper and lower blade holders. Replace table insert.

9.Apply blade tension by referring to the section

“ADJUSTING BLADE TENSION”.

ADJUSTING

BLADE TENSION

Tension is applied to the blade when the blade tension lever (A) Fig. 18, has been adjusted and is in the horizontal position as shown. When the blade tension lever (A) is moved to the vertical position, as shown in Fig. 19, blade tension is released.

To adjust blade tension, position lever (A) in the vertical position, as shown in Fig. 19. To increase tension, turn lever (A) clockwise and to decrease tension turn lever (A) counterclockwise. When adjusting tension, turn lever

Adjusting the blade for proper tension is usually accomplished by trial and error. One method is to pull back on the blade tension lever (A) Fig. 19, the blade should start to have tension (resistance) when the blade tension lever is half way between open Fig. 19, and closed Fig. 18. Finer blades require more tensioning while thicker blades require less tension.

C

H

G

A

Fig. 16

F

HE

Fig. 17

A

Fig. 18

A

Fig. 19

9