ADJUSTING

HOLDDOWN

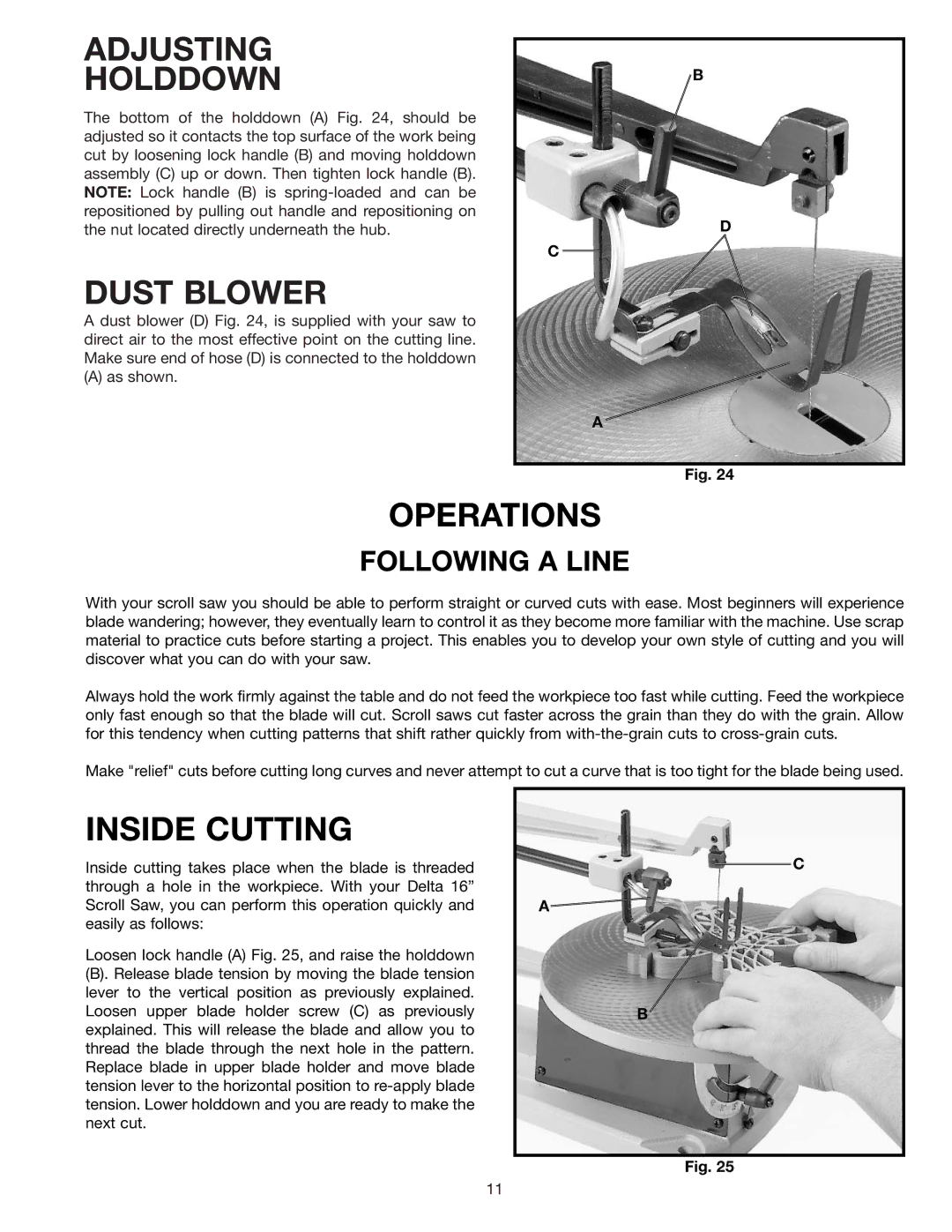

The bottom of the holddown (A) Fig. 24, should be adjusted so it contacts the top surface of the work being cut by loosening lock handle (B) and moving holddown assembly (C) up or down. Then tighten lock handle (B). NOTE: Lock handle (B) is

DUST BLOWER

A dust blower (D) Fig. 24, is supplied with your saw to direct air to the most effective point on the cutting line. Make sure end of hose (D) is connected to the holddown

(A) as shown.

B

D

C

A

Fig. 24

OPERATIONS

FOLLOWING A LINE

With your scroll saw you should be able to perform straight or curved cuts with ease. Most beginners will experience blade wandering; however, they eventually learn to control it as they become more familiar with the machine. Use scrap material to practice cuts before starting a project. This enables you to develop your own style of cutting and you will discover what you can do with your saw.

Always hold the work firmly against the table and do not feed the workpiece too fast while cutting. Feed the workpiece only fast enough so that the blade will cut. Scroll saws cut faster across the grain than they do with the grain. Allow for this tendency when cutting patterns that shift rather quickly from

Make "relief" cuts before cutting long curves and never attempt to cut a curve that is too tight for the blade being used.

INSIDE CUTTING

Inside cutting takes place when the blade is threaded through a hole in the workpiece. With your Delta 16” Scroll Saw, you can perform this operation quickly and easily as follows:

Loosen lock handle (A) Fig. 25, and raise the holddown

(B). Release blade tension by moving the blade tension lever to the vertical position as previously explained. Loosen upper blade holder screw (C) as previously explained. This will release the blade and allow you to thread the blade through the next hole in the pattern. Replace blade in upper blade holder and move blade tension lever to the horizontal position to

C

A![]()

B

Fig. 25

11