6.

7.Assemble table insert (C) Fig. 9, in table as shown. NOTE: Opening in table insert (C) should be positioned toward the front for normal work with the table in the level position and should be positioned toward the right when tilting the table.

FASTENING SCROLL SAW TO SUPPORTING SURFACE

C

Fig. 9

This scroll saw MUST be securely fastened to a stand or workbench using the three holes, two of which are shown at (A) Fig. 10. The third hole is at the rear of the machine.

An alternate method of securing the scroll saw to a sup- porting surface is to fasten the scroll saw to a mounting board. Then securely clamp the mounting board to a stand or workbench using two or more

A

Fig. 10

OPERATING CONTROLS AND ADJUSTMENTS

ON-OFF SWITCH

The

LOCKING SWITCH IN THE “OFF” POSITION

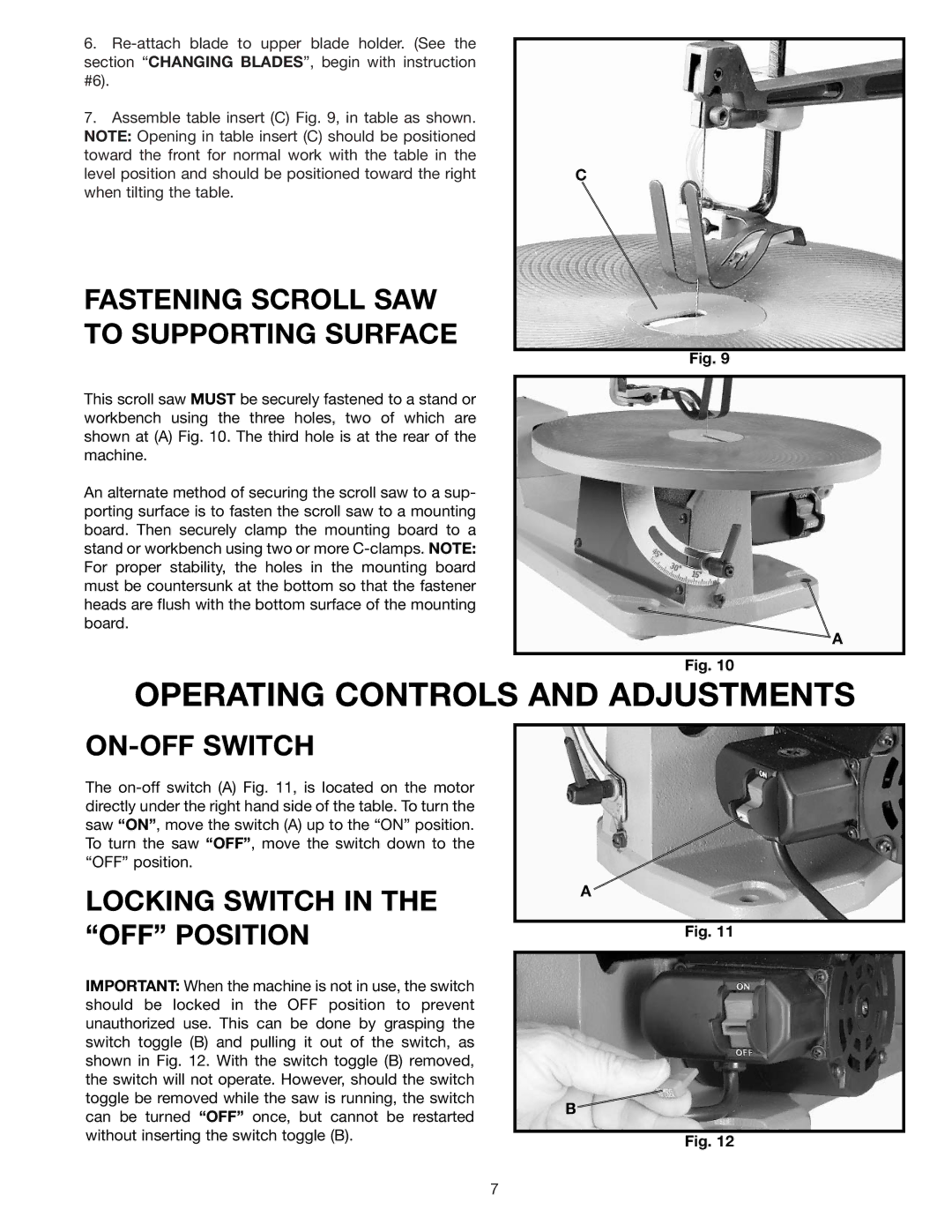

IMPORTANT: When the machine is not in use, the switch should be locked in the OFF position to prevent unauthorized use. This can be done by grasping the switch toggle (B) and pulling it out of the switch, as shown in Fig. 12. With the switch toggle (B) removed, the switch will not operate. However, should the switch toggle be removed while the saw is running, the switch can be turned “OFF” once, but cannot be restarted without inserting the switch toggle (B).

A

Fig. 11

B

Fig. 12

7