SPRAYER CALIBRATION PROCEDURES

NOTE: To avoid wind drift, use lower pressure and higher spray volume.

Guidelines For Sprayer Calibration

Before calibrating your sprayer, first determine whether each nozzle is delivering at a uniform rate. Place quart jars under all nozzles and watch as they fill up. The level should rise uniformly and take the same time (within 10%) for all nozzles to fill the jars. Replace any nozzle showing a discharge rate different from the others.

Calibrating the Sprayer

1.Mark off 660 feet (1/8 mile).

2.Fill the tank with water.

3.Set the sprayer to your desired operating pressure.

4.Turn the sprayer on and drive at the constant speed you will be spraying. Calibration on a road or unplowed field will give different results than on soft cultivated ground. Note tachometer reading so same speed can be main- tained later.

5.Measure the amount of water it takes to refill the tank completely.

6.Calculate the amount applied:

Number of gallons used x 66 (factor) | =Gallons applied |

Spray Swath in Feet | per acre |

Example: If 10 gallons are used in 660 feet and the spray swath is 40 feet, spraying rate is 16.5 gallons per acre.

10 x 66 | = | 660 | or 16.5 gallons per acre |

40 | 40 |

|

7. To calculate the amount of chemical to put in the tank:

Sprayer Tank Size | = | Acres |

| then; | |

Desired GPA | Covered |

| |||

|

| ||||

Recommended amount | x | Acres | = | Amount of | |

chemical per | |||||

of chemical per acre |

| Covered |

| tankful | |

|

|

|

|

| |

Example: If a 500 gallon tank is used and 16.5 gallons per acre are applied, one tank will cover 30.3 acres. If three pounds of chemical are required per acre, then 90 pounds of chemical is required per tankful.

500 | = 30.3 acres covered then; |

16.5 |

|

3 lbs. (gal.) x 30.3 = 90 lbs. (gal.) per tankful

To determine GPA at other nominal speed.

Tractor | Multiply by |

Speed | Speed Factor |

4 mph | 1.25 |

5 mph | 1.00 |

6 mph | .83 |

7.5 mph | .67 |

10 mph | .50 |

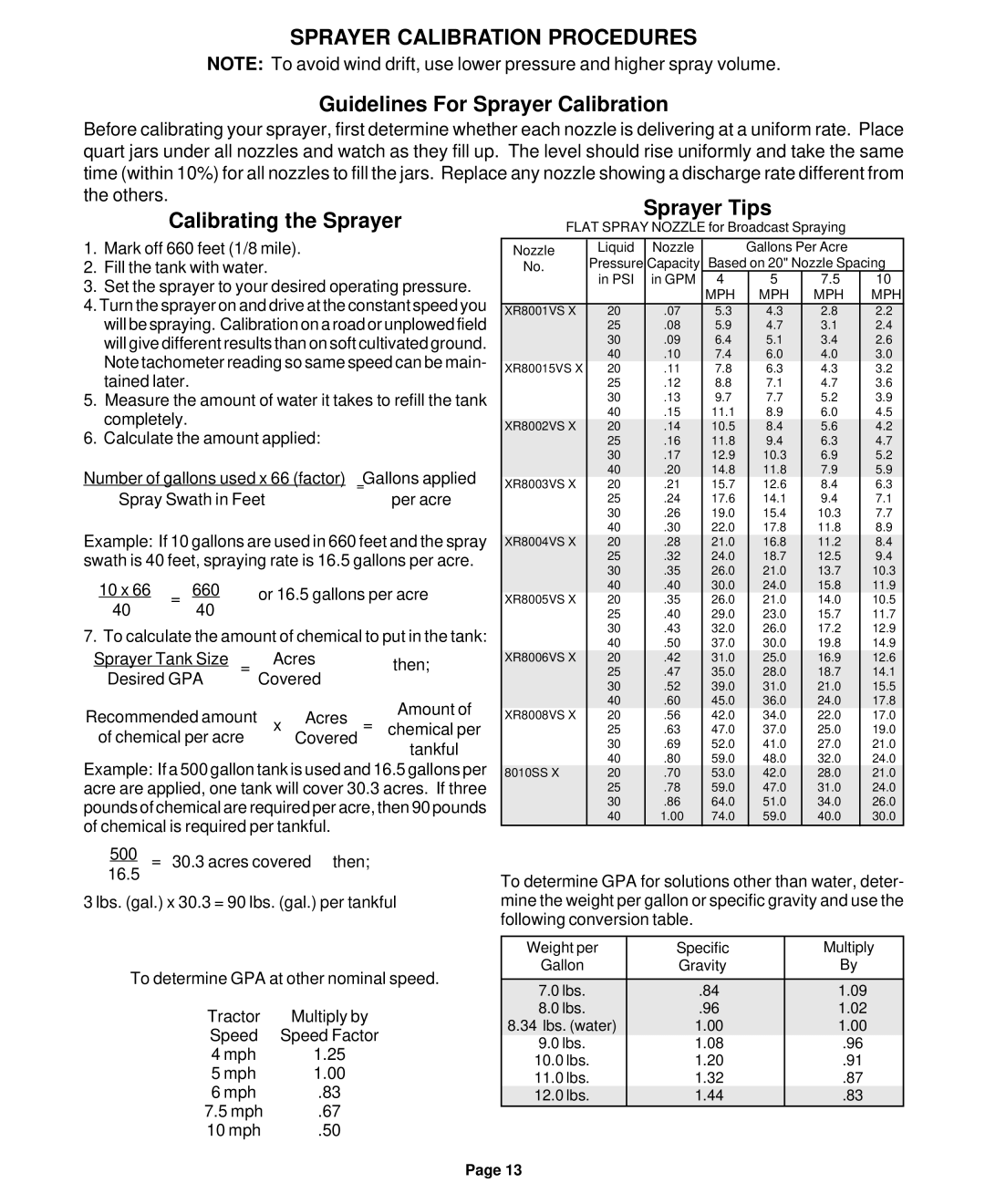

Nozzle | Liquid | Nozzle |

| Gallons Per Acre |

| |

No. | Pressure | Capacity | Based on 20" Nozzle Spacing | |||

| in PSI | in GPM | 4 | 5 | 7.5 | 10 |

|

|

| MPH | MPH | MPH | MPH |

XR8001VS X | 20 | .07 | 5.3 | 4.3 | 2.8 | 2.2 |

| 25 | .08 | 5.9 | 4.7 | 3.1 | 2.4 |

| 30 | .09 | 6.4 | 5.1 | 3.4 | 2.6 |

| 40 | .10 | 7.4 | 6.0 | 4.0 | 3.0 |

XR80015VS X | 20 | .11 | 7.8 | 6.3 | 4.3 | 3.2 |

| 25 | .12 | 8.8 | 7.1 | 4.7 | 3.6 |

| 30 | .13 | 9.7 | 7.7 | 5.2 | 3.9 |

| 40 | .15 | 11.1 | 8.9 | 6.0 | 4.5 |

XR8002VS X | 20 | .14 | 10.5 | 8.4 | 5.6 | 4.2 |

| 25 | .16 | 11.8 | 9.4 | 6.3 | 4.7 |

| 30 | .17 | 12.9 | 10.3 | 6.9 | 5.2 |

| 40 | .20 | 14.8 | 11.8 | 7.9 | 5.9 |

XR8003VS X | 20 | .21 | 15.7 | 12.6 | 8.4 | 6.3 |

| 25 | .24 | 17.6 | 14.1 | 9.4 | 7.1 |

| 30 | .26 | 19.0 | 15.4 | 10.3 | 7.7 |

| 40 | .30 | 22.0 | 17.8 | 11.8 | 8.9 |

XR8004VS X | 20 | .28 | 21.0 | 16.8 | 11.2 | 8.4 |

| 25 | .32 | 24.0 | 18.7 | 12.5 | 9.4 |

| 30 | .35 | 26.0 | 21.0 | 13.7 | 10.3 |

| 40 | .40 | 30.0 | 24.0 | 15.8 | 11.9 |

XR8005VS X | 20 | .35 | 26.0 | 21.0 | 14.0 | 10.5 |

| 25 | .40 | 29.0 | 23.0 | 15.7 | 11.7 |

| 30 | .43 | 32.0 | 26.0 | 17.2 | 12.9 |

| 40 | .50 | 37.0 | 30.0 | 19.8 | 14.9 |

XR8006VS X | 20 | .42 | 31.0 | 25.0 | 16.9 | 12.6 |

| 25 | .47 | 35.0 | 28.0 | 18.7 | 14.1 |

| 30 | .52 | 39.0 | 31.0 | 21.0 | 15.5 |

| 40 | .60 | 45.0 | 36.0 | 24.0 | 17.8 |

XR8008VS X | 20 | .56 | 42.0 | 34.0 | 22.0 | 17.0 |

| 25 | .63 | 47.0 | 37.0 | 25.0 | 19.0 |

| 30 | .69 | 52.0 | 41.0 | 27.0 | 21.0 |

| 40 | .80 | 59.0 | 48.0 | 32.0 | 24.0 |

8010SS X | 20 | .70 | 53.0 | 42.0 | 28.0 | 21.0 |

| 25 | .78 | 59.0 | 47.0 | 31.0 | 24.0 |

| 30 | .86 | 64.0 | 51.0 | 34.0 | 26.0 |

| 40 | 1.00 | 74.0 | 59.0 | 40.0 | 30.0 |

To determine GPA for solutions other than water, deter- mine the weight per gallon or specific gravity and use the following conversion table.

Weight per | Specific | Multiply |

Gallon | Gravity | By |

|

|

|

7.0 lbs. | .84 | 1.09 |

8.0 lbs. | .96 | 1.02 |

8.34 lbs. (water) | 1.00 | 1.00 |

9.0 lbs. | 1.08 | .96 |

10.0 lbs. | 1.20 | .91 |

11.0 lbs. | 1.32 | .87 |

12.0 lbs. | 1.44 | .83 |

|

|

|

Page 13