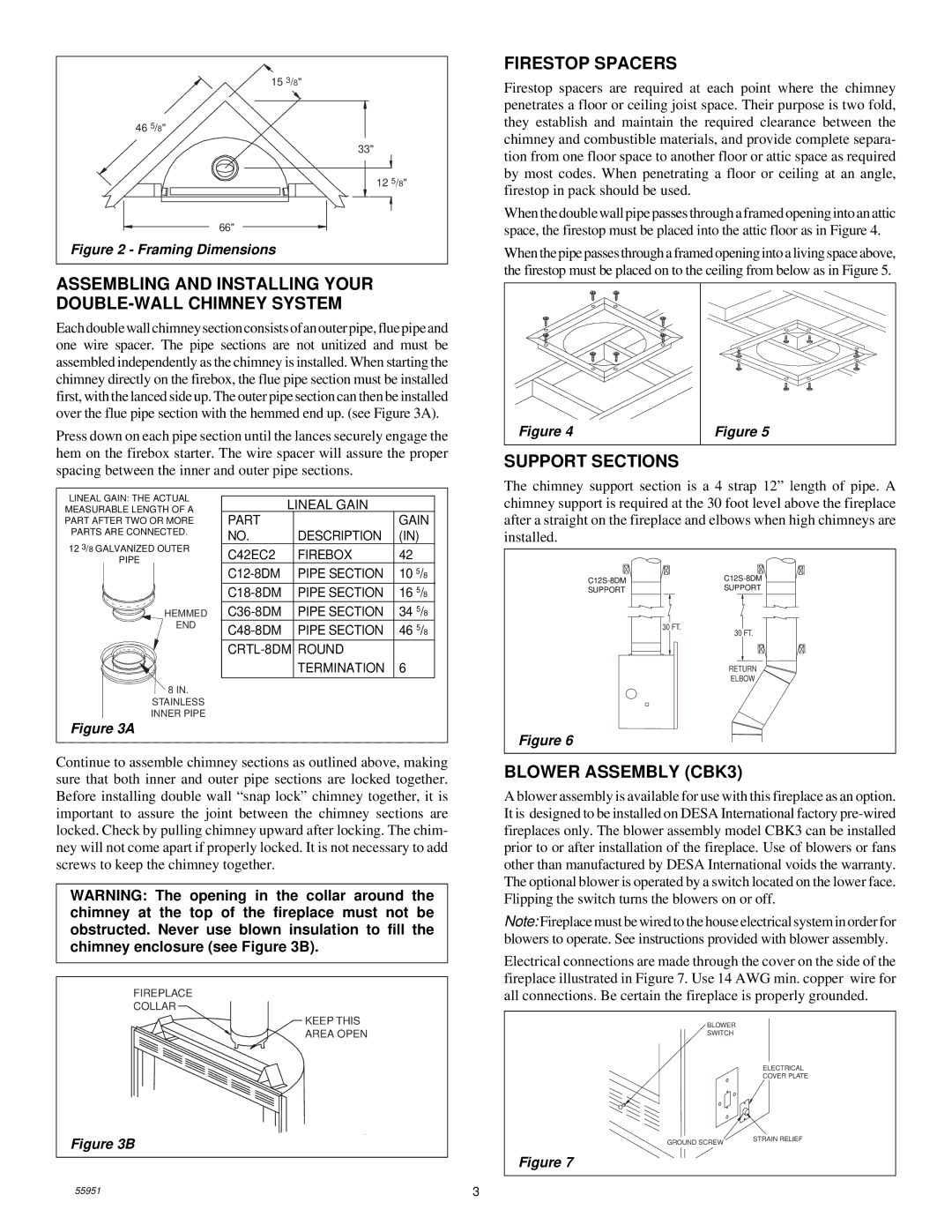

15 3/8" |

46 5/8" |

33" |

12 5/8" |

66" |

Figure 2 - Framing Dimensions |

ASSEMBLING AND INSTALLING YOUR DOUBLE-WALL CHIMNEY SYSTEM

Each double wall chimney section consists of an outer pipe, flue pipe and one wire spacer. The pipe sections are not unitized and must be assembled independently as the chimney is installed. When starting the chimney directly on the firebox, the flue pipe section must be installed first, with the lanced side up. The outer pipe section can then be installed over the flue pipe section with the hemmed end up. (see Figure 3A).

Press down on each pipe section until the lances securely engage the hem on the firebox starter. The wire spacer will assure the proper spacing between the inner and outer pipe sections.

LINEAL GAIN: THE ACTUAL |

| LINEAL GAIN |

| |

MEASURABLE LENGTH OF A | PART | GAIN | ||

PART AFTER TWO OR MORE |

| |||

PARTS ARE CONNECTED. | NO. | DESCRIPTION | (IN) | |

12 3/8 GALVANIZED OUTER | ||||

C42EC2 | FIREBOX | 42 | ||

PIPE | ||||

|

|

| ||

| PIPE SECTION | 10 5/8 | ||

| PIPE SECTION | 16 5/8 | ||

HEMMED | PIPE SECTION | 34 5/8 | ||

END | PIPE SECTION | 46 5/8 | ||

|

| |||

|

| TERMINATION | 6 | |

8IN.

STAINLESS INNER PIPE

Figure 3A

Continue to assemble chimney sections as outlined above, making sure that both inner and outer pipe sections are locked together. Before installing double wall “snap lock” chimney together, it is important to assure the joint between the chimney sections are locked. Check by pulling chimney upward after locking. The chim- ney will not come apart if properly locked. It is not necessary to add screws to keep the chimney together.

WARNING: The opening in the collar around the chimney at the top of the fireplace must not be obstructed. Never use blown insulation to fill the chimney enclosure (see Figure 3B).

FIREPLACE

COLLAR

KEEP THIS

AREA OPEN

Figure 3B

FIRESTOP SPACERS

Firestop spacers are required at each point where the chimney penetrates a floor or ceiling joist space. Their purpose is two fold, they establish and maintain the required clearance between the chimney and combustible materials, and provide complete separa- tion from one floor space to another floor or attic space as required by most codes. When penetrating a floor or ceiling at an angle, firestop in pack should be used.

When the double wall pipe passes through a framed opening into an attic space, the firestop must be placed into the attic floor as in Figure 4.

When the pipe passes through a framed opening into a living space above, the firestop must be placed on to the ceiling from below as in Figure 5.

Figure 4 | Figure 5 |

SUPPORT SECTIONS

The chimney support section is a 4 strap 12” length of pipe. A chimney support is required at the 30 foot level above the fireplace after a straight on the fireplace and elbows when high chimneys are installed.

SUPPORT | SUPPORT |

30 FT.

30 FT.

RETURN

ELBOW

Figure 6

BLOWER ASSEMBLY (CBK3)

A blower assembly is available for use with this fireplace as an option. It is designed to be installed on DESA International factory

Note: Fireplace must be wired to the house electrical system in order for blowers to operate. See instructions provided with blower assembly.

Electrical connections are made through the cover on the side of the fireplace illustrated in Figure 7. Use 14 AWG min. copper wire for all connections. Be certain the fireplace is properly grounded.

BLOWER

SWITCH

ELECTRICAL

COVER PLATE

GROUND SCREW | STRAIN RELIEF |

Figure 7

55951 | 3 |