OWNER’S MANUAL

INSTALLATION

Continued

![]() CAUTION: Use only new, black iron or steel pipe. Inter-

CAUTION: Use only new, black iron or steel pipe. Inter-

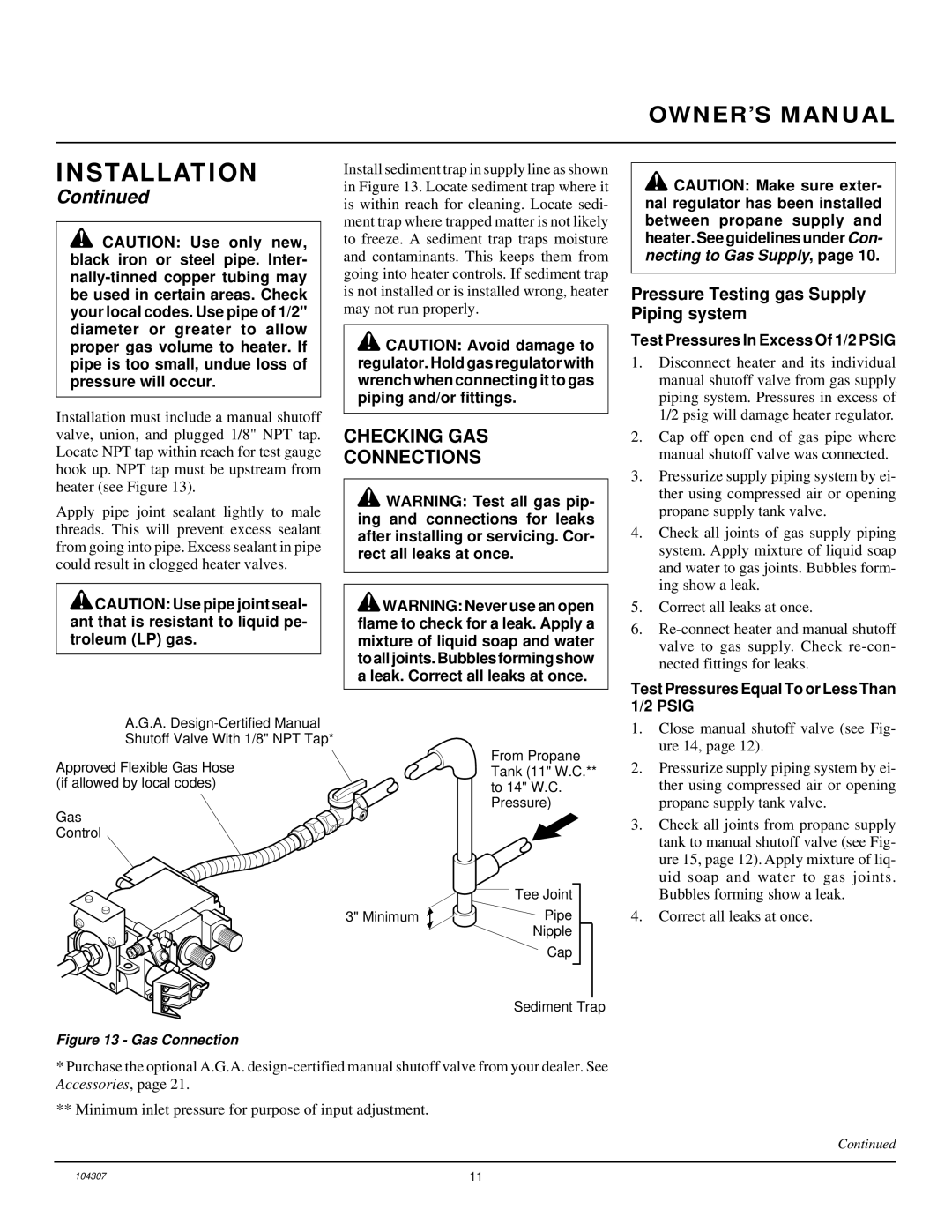

Installation must include a manual shutoff valve, union, and plugged 1/8" NPT tap. Locate NPT tap within reach for test gauge hook up. NPT tap must be upstream from heater (see Figure 13).

Apply pipe joint sealant lightly to male threads. This will prevent excess sealant from going into pipe. Excess sealant in pipe could result in clogged heater valves.

![]() CAUTION: Use pipe joint seal- ant that is resistant to liquid pe- troleum (LP) gas.

CAUTION: Use pipe joint seal- ant that is resistant to liquid pe- troleum (LP) gas.

Install sediment trap in supply line as shown in Figure 13. Locate sediment trap where it is within reach for cleaning. Locate sedi- ment trap where trapped matter is not likely to freeze. A sediment trap traps moisture and contaminants. This keeps them from going into heater controls. If sediment trap is not installed or is installed wrong, heater may not run properly.

![]() CAUTION: Avoid damage to regulator. Hold gas regulator with wrench when connecting it to gas piping and/or fittings.

CAUTION: Avoid damage to regulator. Hold gas regulator with wrench when connecting it to gas piping and/or fittings.

CHECKING GAS

CONNECTIONS

![]() WARNING: Test all gas pip- ing and connections for leaks after installing or servicing. Cor- rect all leaks at once.

WARNING: Test all gas pip- ing and connections for leaks after installing or servicing. Cor- rect all leaks at once.

![]() WARNING: Never use an open flame to check for a leak. Apply a mixture of liquid soap and water to all joints. Bubbles forming show a leak. Correct all leaks at once.

WARNING: Never use an open flame to check for a leak. Apply a mixture of liquid soap and water to all joints. Bubbles forming show a leak. Correct all leaks at once.

![]() CAUTION: Make sure exter- nal regulator has been installed between propane supply and heater. See guidelines under Con- necting to Gas Supply, page 10.

CAUTION: Make sure exter- nal regulator has been installed between propane supply and heater. See guidelines under Con- necting to Gas Supply, page 10.

Pressure Testing gas Supply Piping system

Test Pressures In Excess Of 1/2 PSIG

1.Disconnect heater and its individual manual shutoff valve from gas supply piping system. Pressures in excess of 1/2 psig will damage heater regulator.

2.Cap off open end of gas pipe where manual shutoff valve was connected.

3.Pressurize supply piping system by ei- ther using compressed air or opening propane supply tank valve.

4.Check all joints of gas supply piping system. Apply mixture of liquid soap and water to gas joints. Bubbles form- ing show a leak.

5.Correct all leaks at once.

6.

Test Pressures Equal To or Less Than 1/2 PSIG

A.G.A.

Shutoff Valve With 1/8" NPT Tap*

From Propane

Approved Flexible Gas Hose | Tank (11" W.C.** | |

(if allowed by local codes) | ||

to 14" W.C. | ||

| ||

Gas | Pressure) | |

| ||

Control |

| |

| Tee Joint | |

3" Minimum | Pipe | |

| Nipple | |

| Cap | |

| Sediment Trap |

Figure 13 - Gas Connection

*Purchase the optional A.G.A.

**Minimum inlet pressure for purpose of input adjustment.

1.Close manual shutoff valve (see Fig- ure 14, page 12).

2.Pressurize supply piping system by ei- ther using compressed air or opening propane supply tank valve.

3.Check all joints from propane supply tank to manual shutoff valve (see Fig- ure 15, page 12). Apply mixture of liq- uid soap and water to gas joints. Bubbles forming show a leak.

4.Correct all leaks at once.

Continued

104307 | 11 |