LFP33PR specifications

Desa LFP33PR is a notable model within the LFP series, renowned for its advanced features and superior technology. Designed primarily for both residential and commercial applications, the LFP33PR combines efficiency with user-friendly functionality.One of the standout features of the Desa LFP33PR is its robust energy performance. It is equipped with an advanced heating element that maximizes energy output while minimizing consumption. This energy-efficient design not only reduces utility costs but also aligns with contemporary sustainability goals, making it an environmentally friendly choice for users.

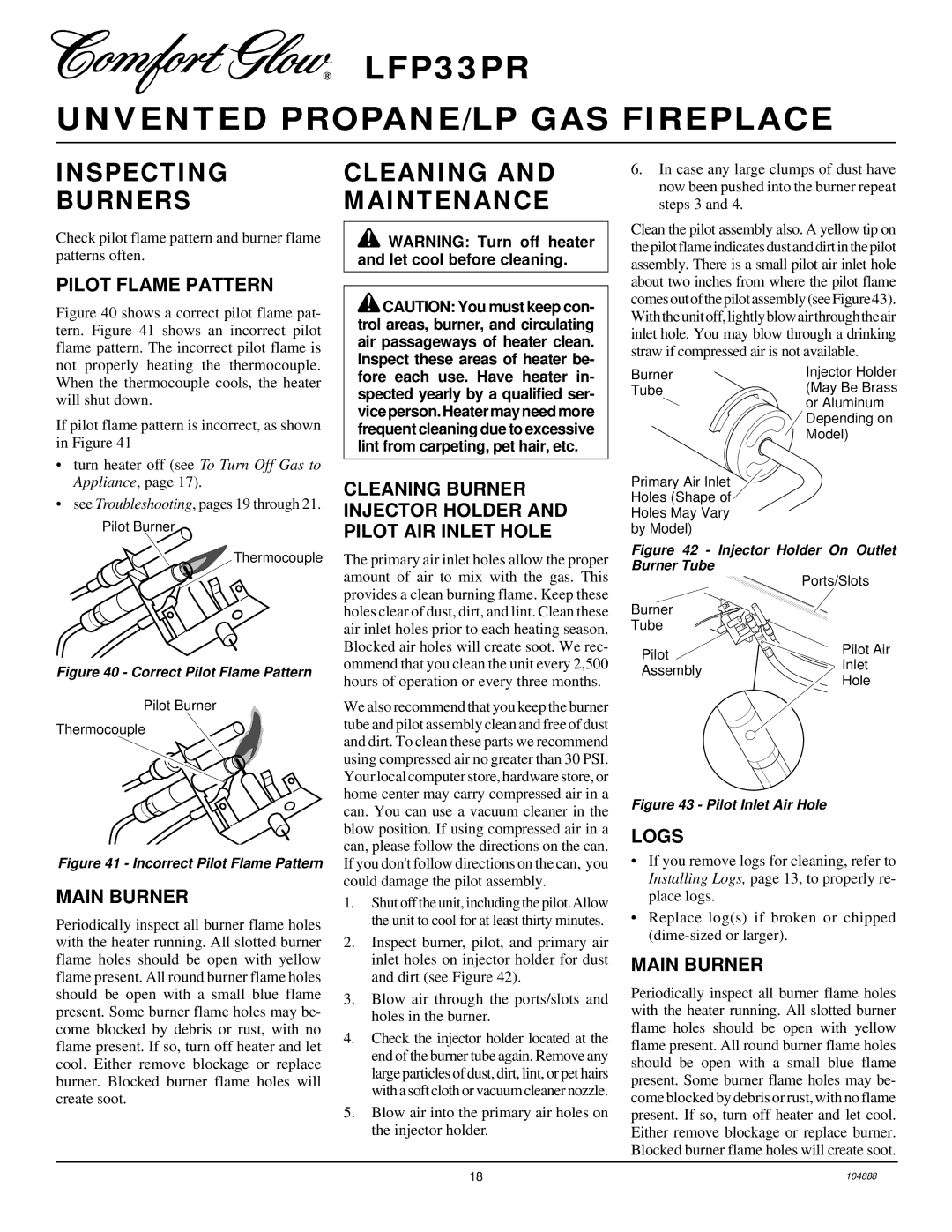

In terms of safety, the Desa LFP33PR incorporates multiple safety mechanisms. These include an automatic shut-off feature that activates when overheating is detected. Additionally, it comes with a built-in flame sensor and a robust housing design that prevents any risk of accidental burns. This focus on safety ensures peace of mind for users, whether in a family home, office environment, or industrial setting.

The LFP33PR also boasts a compact and portable design, making it easy to move from room to room or to different areas within a facility. This portability does not compromise its durability; the unit is constructed with high-quality materials designed to withstand regular use.

Furthermore, the technology integrated into the Desa LFP33PR elevates user experience significantly. It features an intuitive control panel that allows for easy temperature adjustments and timer settings. Users can also benefit from remote control functionality, enabling them to regulate the heating system from a distance.

The aesthetic design of the LFP33PR is another appealing characteristic. Its sleek exterior is available in various colors and can blend seamlessly with different interior styles. This attention to aesthetic detail not only enhances functionality but also ensures that the device adds an element of style to any space.

Maintenance of the Desa LFP33PR is straightforward, with features that allow easy access for cleaning and servicing. The design also minimizes dust accumulation, ensuring optimal performance over time.

In summary, the Desa LFP33PR is a state-of-the-art heating solution, characterized by its efficiency, safety, portability, user-friendly technology, and appealing aesthetics. Its thoughtful design and advanced features make it an excellent choice for those seeking both comfort and reliability in their heating appliances.