8

VENTING INSTALLATION INSTRUCTIONS

Installation Planning

VENTING INSTALLATION INSTRUCTIONS

Continued

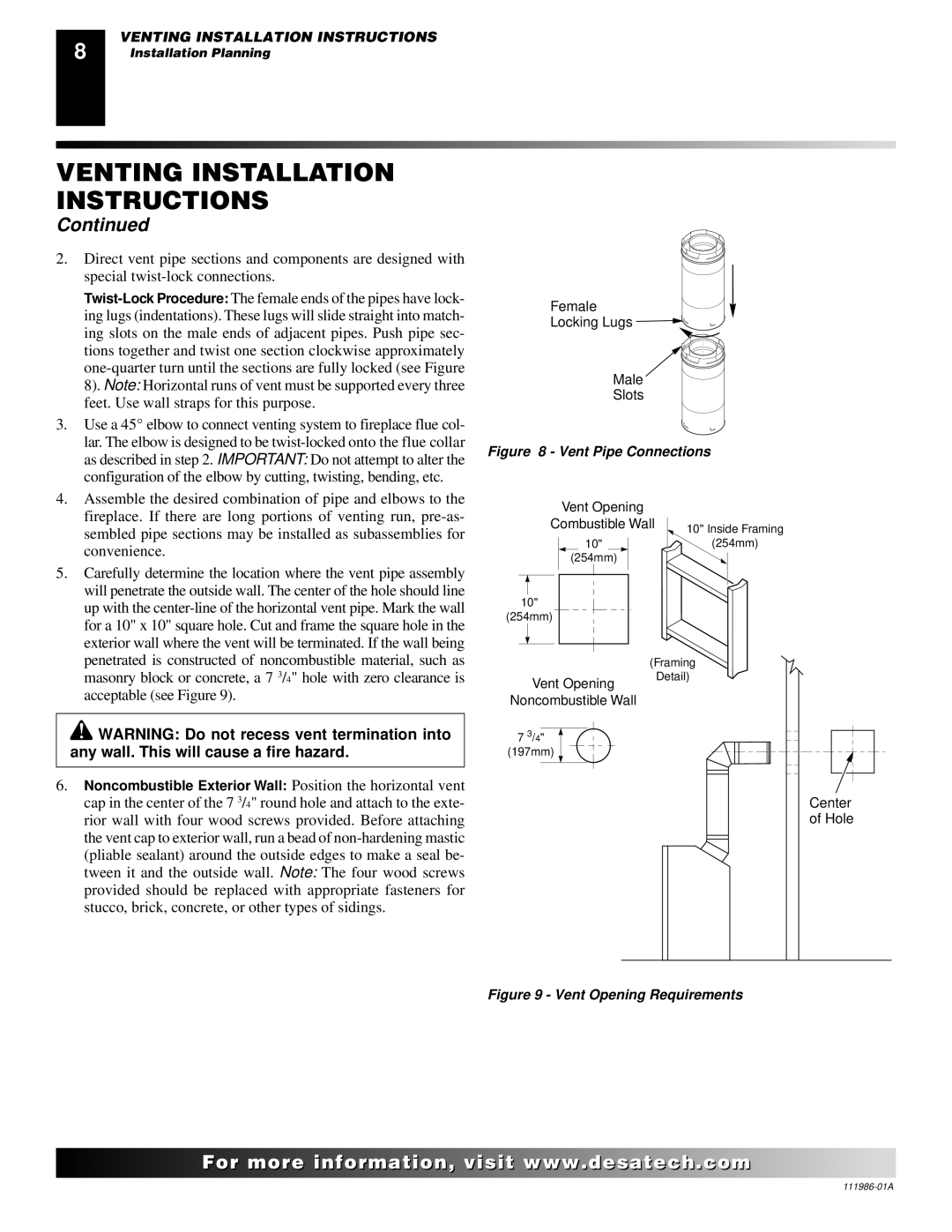

2.Direct vent pipe sections and components are designed with special

3.Use a 45° elbow to connect venting system to fireplace flue col- lar. The elbow is designed to be

4.Assemble the desired combination of pipe and elbows to the fireplace. If there are long portions of venting run,

5.Carefully determine the location where the vent pipe assembly will penetrate the outside wall. The center of the hole should line up with the

![]() WARNING: Do not recess vent termination into any wall. This will cause a fire hazard.

WARNING: Do not recess vent termination into any wall. This will cause a fire hazard.

6.Noncombustible Exterior Wall: Position the horizontal vent cap in the center of the 7 3/4" round hole and attach to the exte- rior wall with four wood screws provided. Before attaching the vent cap to exterior wall, run a bead of

Female

Locking Lugs

Male

Slots

Figure 8 - Vent Pipe Connections

Vent Opening |

|

|

Combustible Wall | 10" Inside Framing | |

|

| |

10" |

| (254mm) |

(254mm) |

|

|

10" |

|

|

(254mm) |

|

|

| (Framing | |

Vent Opening |

| Detail) |

|

| |

Noncombustible Wall |

|

|

7 3/4" |

|

|

(197mm) |

|

|

|

| Center |

|

| of Hole |

Figure 9 - Vent Opening Requirements

![]()

![]()

![]()

![]()

![]() For

For![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() .

.![]()

![]()

![]()

![]() .com

.com![]()

![]()

![]()

![]()

![]()