TROUBLESHOOTING

Continued

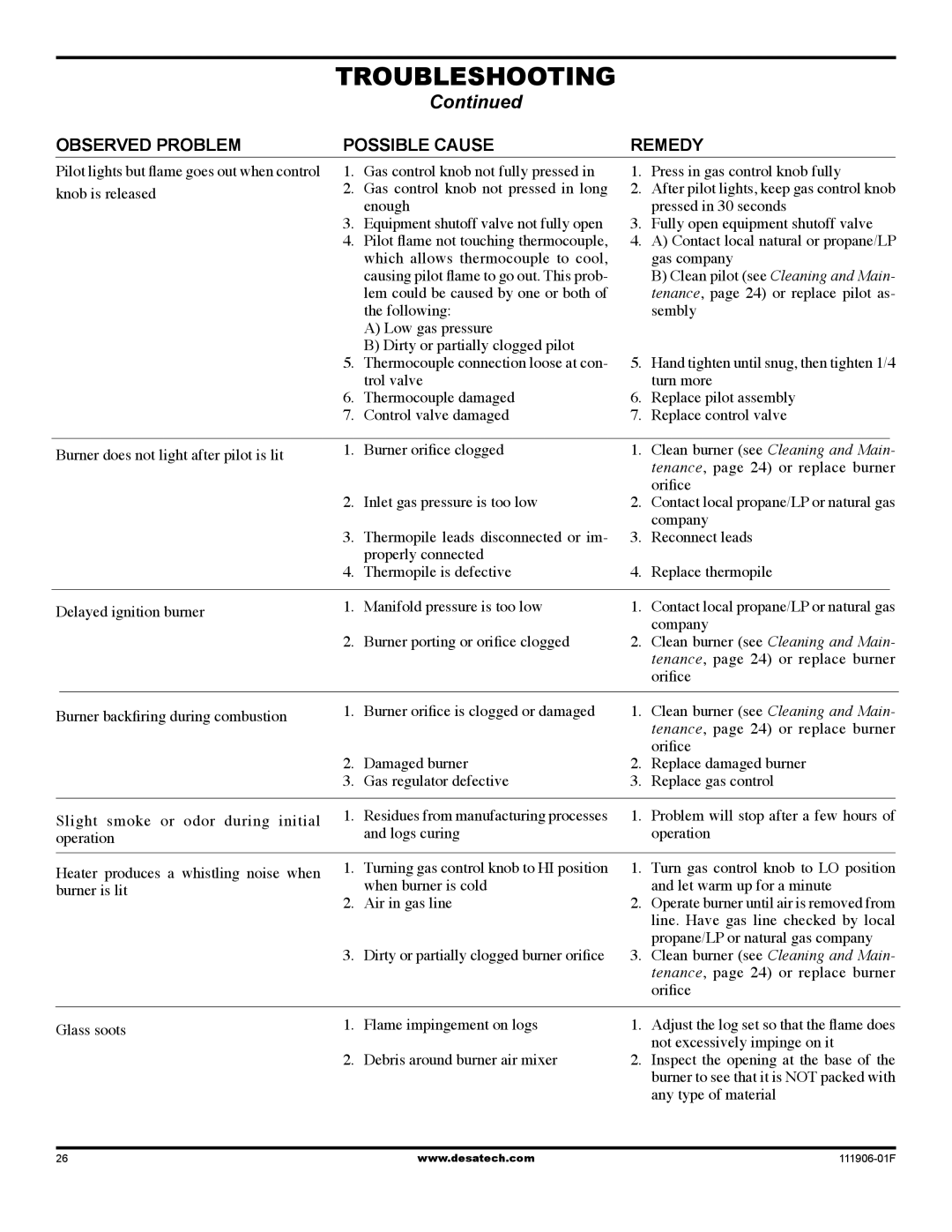

| OBSERVED PROBLEM | POSSIBLE CAUSE | REMEDY |

| |||||

|

|

|

|

|

|

|

|

|

|

| Pilot lights but flame goes out when control | 1. | Gas control knob not fully pressed in | 1. | Press in gas control knob fully |

| |||

| knob is released | 2. | Gas control knob not pressed in long | 2. | After pilot lights, keep gas control knob |

| |||

|

|

| 3. | enough | 3. | pressed in 30 seconds |

| ||

|

|

| Equipment shutoff valve not fully open | Fully open equipment shutoff valve |

| ||||

|

|

| 4. | Pilot flame not touching thermocouple, | 4. | A) Contact local natural or propane/LP |

| ||

|

|

|

| which allows thermocouple to cool, |

| gas company |

| ||

|

|

|

| causing pilot flame to go out. This prob- |

| B) Clean pilot (see Cleaning and Main- |

| ||

|

|

|

| lem could be caused by one or both of |

| tenance, page 24) or replace pilot as- |

| ||

|

|

|

| the following: |

| sembly |

| ||

|

|

|

| A) Low gas pressure |

|

|

|

|

|

|

|

| 5. | B) Dirty or partially clogged pilot | 5. | Hand tighten until snug, then tighten 1/4 |

| ||

|

|

| Thermocouple connection loose at con- |

| |||||

|

|

| 6. | trol valve | 6. | turn more |

| ||

|

|

| Thermocouple damaged | Replace pilot assembly |

| ||||

|

|

| 7. | Control valve damaged | 7. | Replace control valve |

| ||

|

|

|

|

|

| - |

| ||

| Burner does not light after pilot is lit | 1. | Burner orifice clogged | 1. | Clean burner (see Cleaning and Main |

| |||

|

|

|

|

|

| tenance, page 24) or replace burner |

| ||

|

|

| 2. | Inlet gas pressure is too low | 2. | orifice |

| ||

|

|

| Contact local propane/LP or natural gas |

| |||||

|

|

| 3. | Thermopile leads disconnected or im- | 3. | company |

| ||

|

|

| Reconnect leads |

| |||||

|

|

| 4. | properly connected | 4. | Replace thermopile |

|

| |

|

|

| Thermopile is defective |

| |||||

| Delayed ignition burner | 1. | Manifold pressure is too low | 1. | Contact local propane/LP or natural gas |

| |||

|

|

| 2. | Burner porting or orifice clogged | 2. | company |

| ||

|

|

| Clean burner (see Cleaning and Main- |

| |||||

|

|

|

|

|

| tenance, page 24) or replace burner |

| ||

|

|

|

|

|

| orifice |

| ||

| Burner backfiring during combustion | 1. | Burner orifice is clogged or damaged | 1. | Clean burner (see Cleaning and Main- |

| |||

|

|

|

|

|

| tenance, page 24) or replace burner |

| ||

|

|

| 2. | Damaged burner | 2. | orifice |

| ||

|

|

| Replace damaged burner |

| |||||

|

|

| 3. | Gas regulator defective | 3. | Replace gas control |

|

| |

| Slight smoke or odor during initial | 1. | Residues from manufacturing processes | 1. | Problem will stop after a few hours of |

| |||

| operation |

| and logs curing |

| operation |

|

| ||

| Heater produces a whistling noise when | 1. | Turning gas control knob to HI position | 1. | Turn gas control knob to LO position |

| |||

| burner is lit | 2. | when burner is cold | 2. | and let warm up for a minute |

| |||

|

|

| Air in gas line | Operate burner until air is removed from |

| ||||

|

|

|

|

|

| line. Have gas line checked by local |

| ||

|

|

| 3. | Dirty or partially clogged burner orifice | 3. | propane/LP or natural gas company |

| ||

|

|

| Clean burner (see Cleaning and Main- |

| |||||

|

|

|

|

|

| tenance, page 24) or replace burner |

| ||

|

|

|

|

|

| orifice |

| ||

| Glass soots | 1. | Flame impingement on logs | 1. | Adjust the log set so that the flame does |

| |||

|

|

| 2. | Debris around burner air mixer | 2. | not excessively impinge on it |

| ||

|

|

| Inspect the opening at the base of the |

| |||||

|

|

|

|

|

| burner to see that it is NOT packed with |

| ||

|

|

|

|

|

| any type of material |

| ||

26 | www.desatech.com |