Cutting Base Molding up to

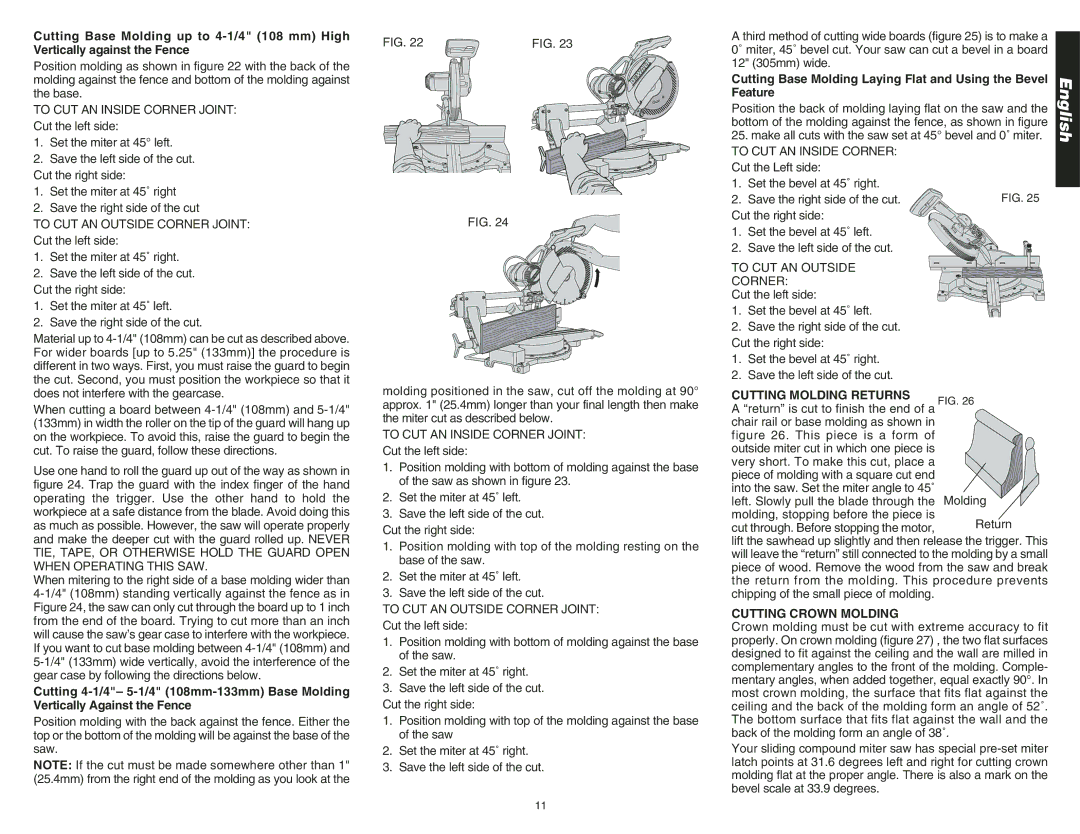

Position molding as shown in figure 22 with the back of the molding against the fence and bottom of the molding against the base.

TO CUT AN INSIDE CORNER JOINT: Cut the left side:

1.Set the miter at 45° left.

2.Save the left side of the cut. Cut the right side:

1.Set the miter at 45˚ right

2.Save the right side of the cut

TO CUT AN OUTSIDE CORNER JOINT: Cut the left side:

1.Set the miter at 45˚ right.

2.Save the left side of the cut. Cut the right side:

1.Set the miter at 45˚ left.

2.Save the right side of the cut.

Material up to

When cutting a board between

Use one hand to roll the guard up out of the way as shown in figure 24. Trap the guard with the index finger of the hand operating the trigger. Use the other hand to hold the workpiece at a safe distance from the blade. Avoid doing this as much as possible. However, the saw will operate properly and make the deeper cut with the guard rolled up. NEVER TIE, TAPE, OR OTHERWISE HOLD THE GUARD OPEN WHEN OPERATING THIS SAW.

When mitering to the right side of a base molding wider than

Cutting

Position molding with the back against the fence. Either the top or the bottom of the molding will be against the base of the saw.

NOTE: If the cut must be made somewhere other than 1" (25.4mm) from the right end of the molding as you look at the

FIG. 22 | FIG. 23 |

FIG. 24

molding positioned in the saw, cut off the molding at 90° approx. 1" (25.4mm) longer than your final length then make the miter cut as described below.

TO CUT AN INSIDE CORNER JOINT: Cut the left side:

1.Position molding with bottom of molding against the base of the saw as shown in figure 23.

2.Set the miter at 45˚ left.

3.Save the left side of the cut.

Cut the right side:

1.Position molding with top of the molding resting on the base of the saw.

2.Set the miter at 45˚ left.

3.Save the left side of the cut.

TO CUT AN OUTSIDE CORNER JOINT:

Cut the left side:

1.Position molding with bottom of molding against the base of the saw.

2.Set the miter at 45˚ right.

3.Save the left side of the cut.

Cut the right side:

1.Position molding with top of the molding against the base of the saw

2.Set the miter at 45˚ right.

3.Save the left side of the cut.

A third method of cutting wide boards (figure 25) is to make a 0˚ miter, 45˚ bevel cut. Your saw can cut a bevel in a board 12" (305mm) wide.

Cutting Base Molding Laying Flat and Using the Bevel Feature

Position the back of molding laying flat on the saw and the bottom of the molding against the fence, as shown in figure

25.make all cuts with the saw set at 45° bevel and 0˚ miter.

TO CUT AN INSIDE CORNER: Cut the Left side:

1.Set the bevel at 45˚ right.

2. Save the right side of the cut. | FIG. 25 |

Cut the right side:

1. Set the bevel at 45˚ left.

2. Save the left side of the cut.

TO CUT AN OUTSIDE

CORNER:

Cut the left side:

1.Set the bevel at 45˚ left.

2.Save the right side of the cut. Cut the right side:

1.Set the bevel at 45˚ right.

2.Save the left side of the cut.

CUTTING MOLDING RETURNS | FIG. 26 |

A “return” is cut to finish the end of a | |

chair rail or base molding as shown in |

|

figure 26. This piece is a form of |

|

outside miter cut in which one piece is |

|

very short. To make this cut, place a |

|

piece of molding with a square cut end |

|

into the saw. Set the miter angle to 45˚ | Molding |

left. Slowly pull the blade through the | |

molding, stopping before the piece is | Return |

cut through. Before stopping the motor, |

lift the sawhead up slightly and then release the trigger. This will leave the “return” still connected to the molding by a small piece of wood. Remove the wood from the saw and break the return from the molding. This procedure prevents chipping of the small piece of molding.

CUTTING CROWN MOLDING

Crown molding must be cut with extreme accuracy to fit properly. On crown molding (figure 27) , the two flat surfaces designed to fit against the ceiling and the wall are milled in complementary angles to the front of the molding. Comple- mentary angles, when added together, equal exactly 90°. In most crown molding, the surface that fits flat against the ceiling and the back of the molding form an angle of 52˚. The bottom surface that fits flat against the wall and the back of the molding form an angle of 38˚.

Your sliding compound miter saw has special

English

11