English

Drilling

![]() WARNING: To reduce the risk of personal injury, ALWAYS ensure workpiece is anchored or clamped firmly. If drilling thin material, use a wood

WARNING: To reduce the risk of personal injury, ALWAYS ensure workpiece is anchored or clamped firmly. If drilling thin material, use a wood

1.Use sharp drill bits only. For WOOD, use twist drill bits, spade bits, power auger bits, or hole saws. For METAL, use steel twist drill bits or hole saws.

2.Always apply pressure in a straight line with the bit. Use enough pressure to keep drill biting, but do not push hard enough to stall the motor or deflect the bit.

3.Hold tool firmly with both hands to control the twisting action of the drill.

4.IF DRILL STALLS, it is usually because it is being overloaded or improperly used. RELEASE TRIGGER IMMEDIATELY, remove drill bit from work, and determine cause of stalling. DO NOT

CLICK TRIGGER ON AND OFF IN AN ATTEMPT TO START A STALLED DRILL — THIS CAN DAMAGE THE DRILL.

5.To minimize stalling or breaking through the material, reduce pressure on drill and ease the bit through the last fractional part of the hole.

6.Keep the motor running when pulling the bit back out of a drilled hole. This will help prevent jamming.

7.With variable speed drills there is no need to center punch the point to be drilled. Use a slow speed to start the hole and accelerate by squeezing the trigger harder when the hole is deep enough to drill without the bit skipping out.

DRILLING IN METAL

Start drilling with slow speed and increase to full power while applying firm pressure on the tool. A smooth even flow of metal chips indicates the proper drilling rate. Use a cutting lubricant when drilling metals. The exceptions are cast iron and brass which should be drilled dry.

NOTE: Large [5/16" (8 mm) to 1/2" (13 mm)] holes in steel can be made easier if a pilot hole [5/32" (4 mm) to 3/16" (5 mm)] is drilled first.

DRILLING IN WOOD

Start drilling with slow speed and increase to full power while applying firm pressure on the tool. Holes in wood can be made with the same twist drills used for metal. These bits may overheat unless pulled out frequently to clear chips from the flutes. Work that is apt to splinter should be backed up with a block of wood.

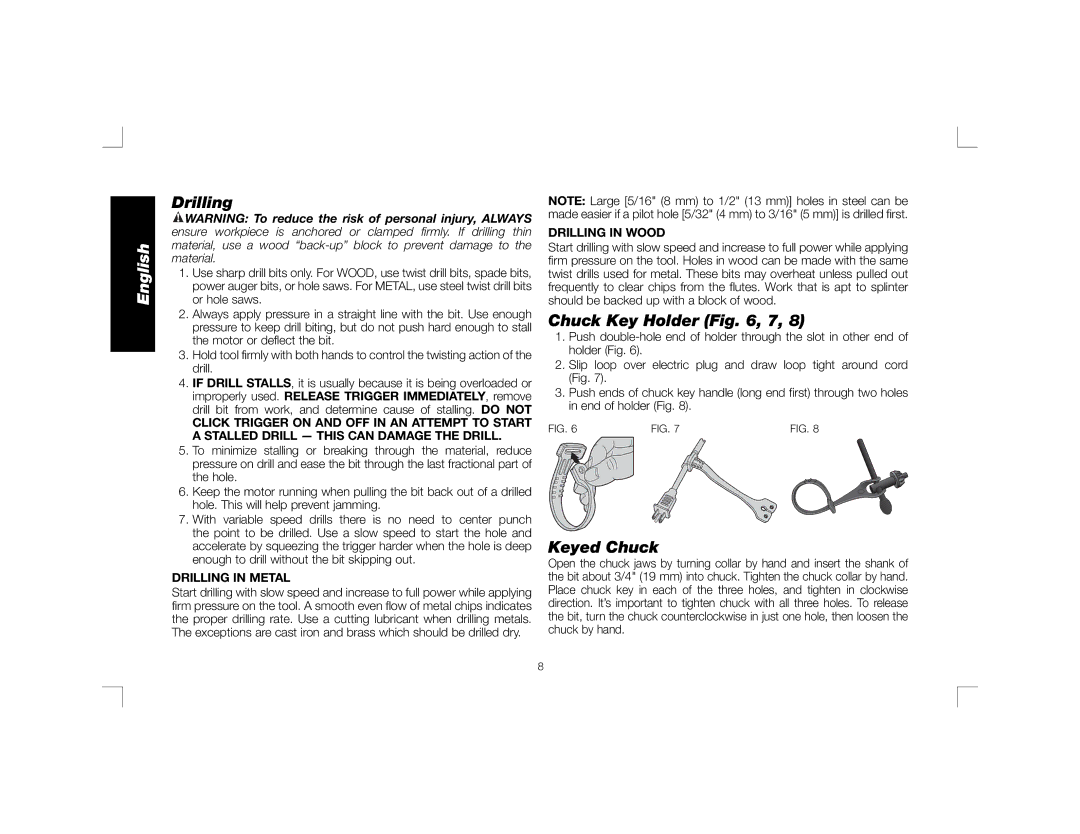

Chuck Key Holder (Fig. 6, 7, 8)

1.Push

2.Slip loop over electric plug and draw loop tight around cord (Fig. 7).

3.Push ends of chuck key handle (long end first) through two holes in end of holder (Fig. 8).

FIG. 6 | FIG. 7 | FIG. 8 |

Keyed Chuck

Open the chuck jaws by turning collar by hand and insert the shank of the bit about 3/4" (19 mm) into chuck. Tighten the chuck collar by hand. Place chuck key in each of the three holes, and tighten in clockwise direction. It’s important to tighten chuck with all three holes. To release the bit, turn the chuck counterclockwise in just one hole, then loosen the chuck by hand.

8