DWE7490, DWE7491 specifications

The DeWalt DWE7491 and DWE7490 are two highly regarded table saws in the woodworking community, revered for their performance, versatility, and advanced features. These saws are designed to cater to both professional woodworkers and DIY enthusiasts, making them ideal for a variety of applications.One of the standout features of the DeWalt DWE7491 is its innovative Rack and Pinion telescoping fence system. This system allows users to easily make accurate adjustments for precise cuts and ensures that the fence remains parallel to the blade. The fence can extend up to 32 inches, providing ample support for larger materials. This is especially useful when working with sheet goods or larger workpieces, making it a valuable tool on the job site.

The DWE7491 also boasts a powerful 2,000-watt motor that delivers a no-load speed of 4,800 RPM. This high speed allows for smooth, clean cuts through various materials, including hardwood and softwood. The saw's 10-inch blade is capable of cutting through thick materials with ease, while a blade guard and anti-kickback pawls enhance safety during operation.

Equipped with a portable design, the DWE7491 and DWE7490 feature onboard storage for accessories, which helps keep the workspace organized. Both models come with heavy-duty wheels for easy transportation, making them practical for job sites where mobility is essential.

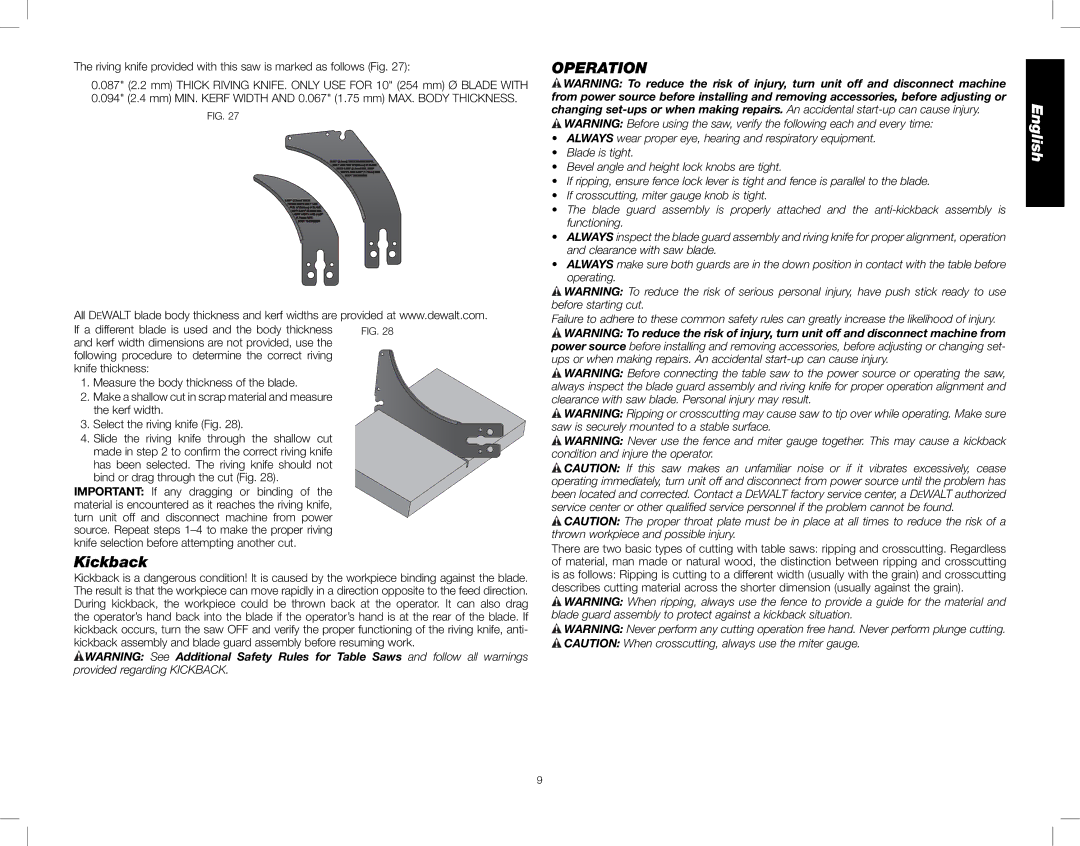

In terms of technology, the DWE7490 model includes a patented Site-Pro Modular Guarding System, which provides the flexibility to adapt to different cutting applications. This system allows users to make quick adjustments to the guard and the riving knife, enhancing user safety while maintaining cutting performance.

Both models offer solid stability due to their durable construction and integrated stand, reducing vibrations and ensuring accurate cuts. The DWE7491 and DWE7490 also feature a large, sturdy surface area, providing ample workspace for materials while enhancing overall safety during operation.

With their advanced features, powerful motors, and portability, the DeWalt DWE7491 and DWE7490 have made a significant impact in the woodworking industry. They cater to various cutting needs, making them valuable investments for anyone looking to enhance their woodworking capabilities.