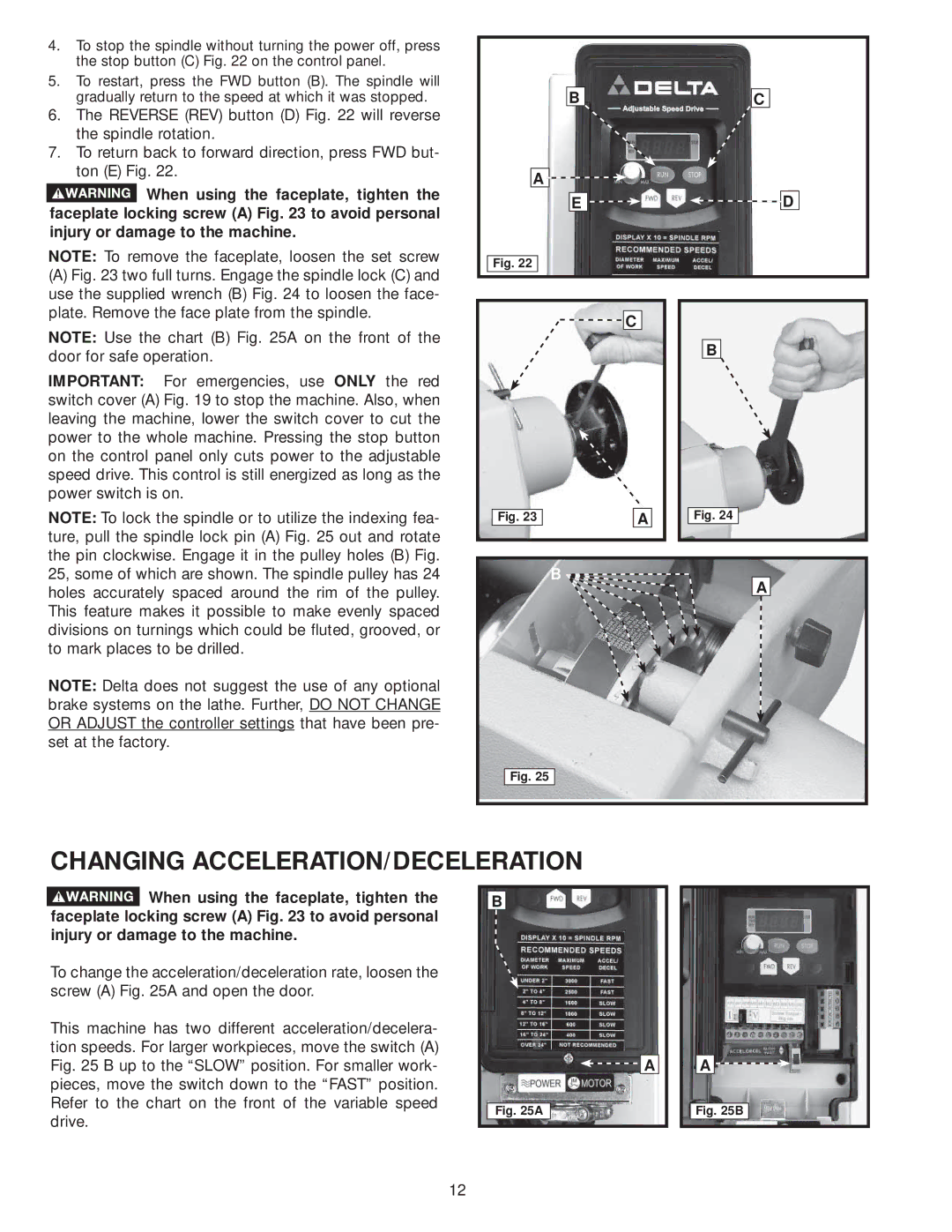

4.To stop the spindle without turning the power off, press the stop button (C) Fig. 22 on the control panel.

5.To restart, press the FWD button (B). The spindle will gradually return to the speed at which it was stopped.

6.The REVERSE (REV) button (D) Fig. 22 will reverse the spindle rotation.

7.To return back to forward direction, press FWD but- ton (E) Fig. 22.

![]() When using the faceplate, tighten the faceplate locking screw (A) Fig. 23 to avoid personal injury or damage to the machine.

When using the faceplate, tighten the faceplate locking screw (A) Fig. 23 to avoid personal injury or damage to the machine.

NOTE: To remove the faceplate, loosen the set screw

(A)Fig. 23 two full turns. Engage the spindle lock (C) and use the supplied wrench (B) Fig. 24 to loosen the face- plate. Remove the face plate from the spindle.

NOTE: Use the chart (B) Fig. 25A on the front of the door for safe operation.

IMPORTANT: For emergencies, use ONLY the red switch cover (A) Fig. 19 to stop the machine. Also, when leaving the machine, lower the switch cover to cut the power to the whole machine. Pressing the stop button on the control panel only cuts power to the adjustable speed drive. This control is still energized as long as the power switch is on.

NOTE: To lock the spindle or to utilize the indexing fea- ture, pull the spindle lock pin (A) Fig. 25 out and rotate the pin clockwise. Engage it in the pulley holes (B) Fig. 25, some of which are shown. The spindle pulley has 24 holes accurately spaced around the rim of the pulley. This feature makes it possible to make evenly spaced divisions on turnings which could be fluted, grooved, or to mark places to be drilled.

NOTE: Delta does not suggest the use of any optional brake systems on the lathe. Further, DO NOT CHANGE OR ADJUST the controller settings that have been pre- set at the factory.

B |

| C |

|

|

|

A

E | D |

Fig. 22

![]()

![]() C

C

B

Fig. 23 |

| A |

| Fig. 24 |

|

|

|

| |

|

|

|

|

|

B

A

Fig. 25

CHANGING ACCELERATION/DECELERATION

![]() When using the faceplate, tighten the faceplate locking screw (A) Fig. 23 to avoid personal injury or damage to the machine.

When using the faceplate, tighten the faceplate locking screw (A) Fig. 23 to avoid personal injury or damage to the machine.

To change the acceleration/deceleration rate, loosen the screw (A) Fig. 25A and open the door.

This machine has two different acceleration/decelera- tion speeds. For larger workpieces, move the switch (A) Fig. 25 B up to the “SLOW” position. For smaller work- pieces, move the switch down to the “FAST” position. Refer to the chart on the front of the variable speed drive.

B

![]()

![]() A

A

Fig. 25A

A ![]()

![]()

Fig. 25B

12