A |

B |

Fig. 76 |

A ![]()

B ![]()

![]()

Fig. 78

A

Fig. 77

B |

A |

Fig. 79 |

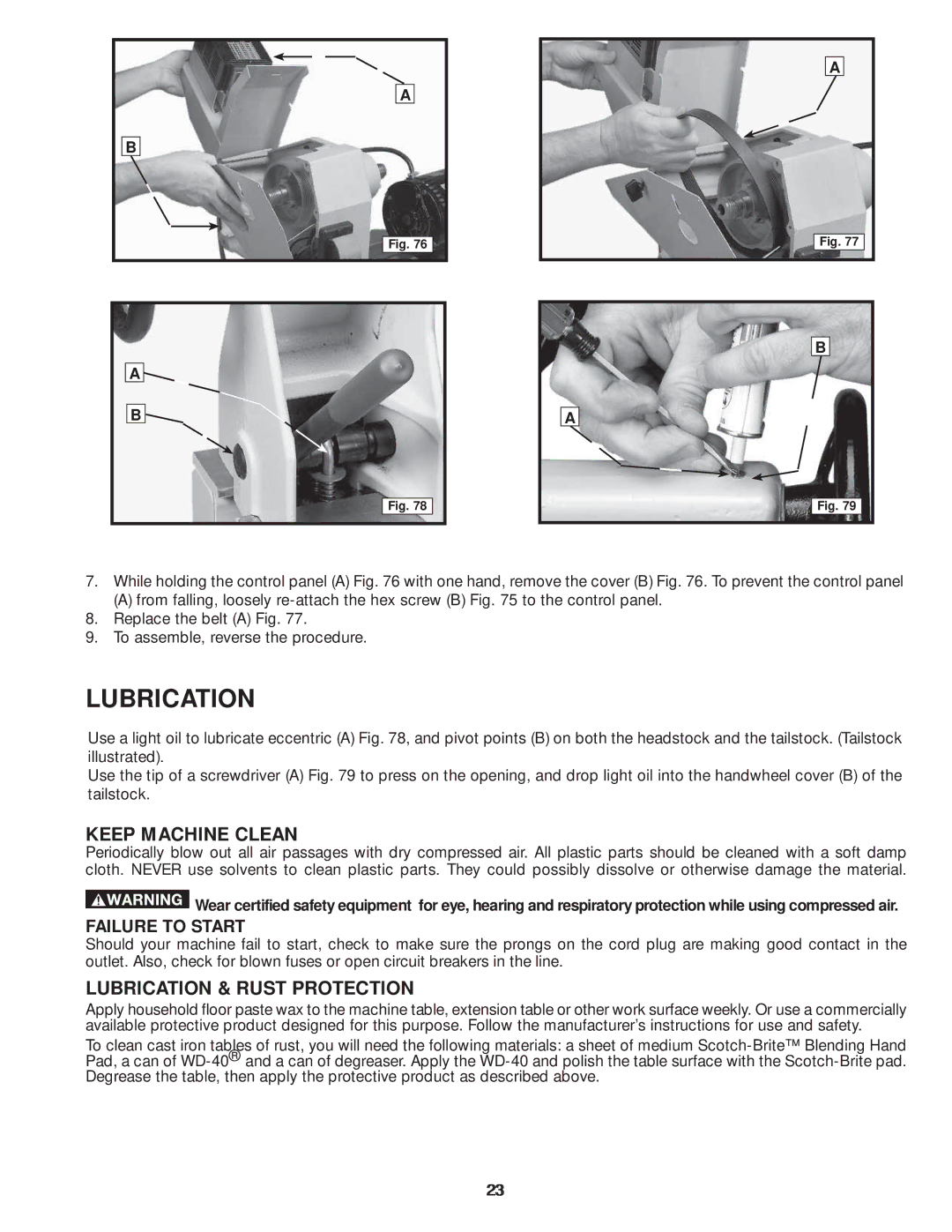

7.While holding the control panel (A) Fig. 76 with one hand, remove the cover (B) Fig. 76. To prevent the control panel

(A) from falling, loosely

8.Replace the belt (A) Fig. 77.

9.To assemble, reverse the procedure.

LUBRICATION

Use a light oil to lubricate eccentric (A) Fig. 78, and pivot points (B) on both the headstock and the tailstock. (Tailstock illustrated).

Use the tip of a screwdriver (A) Fig. 79 to press on the opening, and drop light oil into the handwheel cover (B) of the tailstock.

KEEP MACHINE CLEAN

Periodically blow out all air passages with dry compressed air. All plastic parts should be cleaned with a soft damp cloth. NEVER use solvents to clean plastic parts. They could possibly dissolve or otherwise damage the material.

![]() Wear certified safety equipment for eye, hearing and respiratory protection while using compressed air.

Wear certified safety equipment for eye, hearing and respiratory protection while using compressed air.

FAILURE TO START

Should your machine fail to start, check to make sure the prongs on the cord plug are making good contact in the outlet. Also, check for blown fuses or open circuit breakers in the line.

LUBRICATION & RUST PROTECTION

Apply household floor paste wax to the machine table, extension table or other work surface weekly. Or use a commercially available protective product designed for this purpose. Follow the manufacturer’s instructions for use and safety.

To clean cast iron tables of rust, you will need the following materials: a sheet of medium

23