OUTBOARD TURNING

For workpieces that require additional space for turning, or for the turning of bowls, etc., outboard turning is the answer. To make outboard turnings:

1.Remove the tool rest base and the tailstock from the lathe bed.

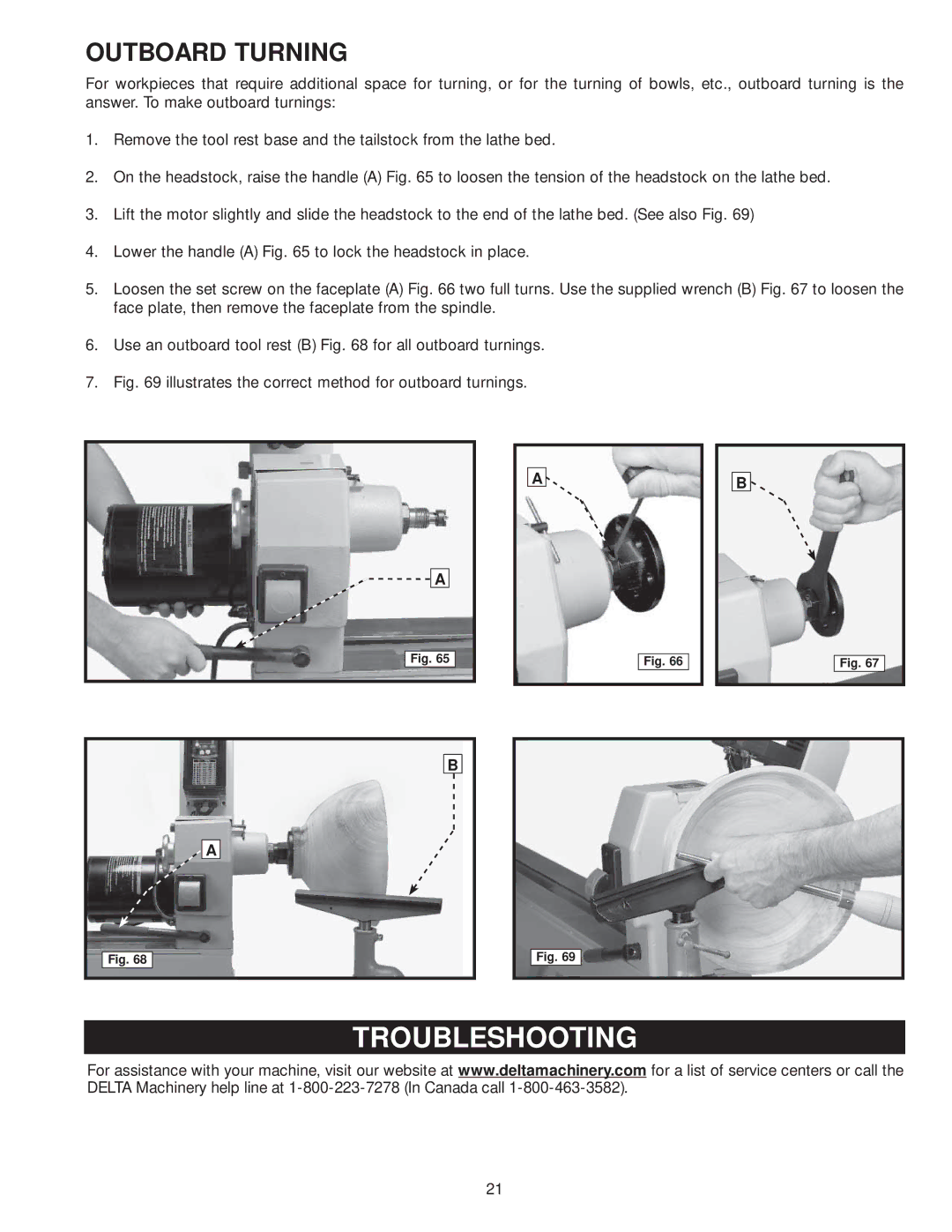

2.On the headstock, raise the handle (A) Fig. 65 to loosen the tension of the headstock on the lathe bed.

3.Lift the motor slightly and slide the headstock to the end of the lathe bed. (See also Fig. 69)

4.Lower the handle (A) Fig. 65 to lock the headstock in place.

5.Loosen the set screw on the faceplate (A) Fig. 66 two full turns. Use the supplied wrench (B) Fig. 67 to loosen the face plate, then remove the faceplate from the spindle.

6.Use an outboard tool rest (B) Fig. 68 for all outboard turnings.

7.Fig. 69 illustrates the correct method for outboard turnings.

![]()

![]() A

A

Fig. 65

B

A

A ![]()

Fig. 66

B ![]()

![]()

Fig. 67

Fig. 68

Fig. 69

TROUBLESHOOTING

For assistance with your machine, visit our website at www.deltamachinery.com for a list of service centers or call the DELTA Machinery help line at

21