DM 2610935540

Maintenance Information

| Service |

| Preventive maintenance performed |

! WARNING | |

| by unauthorized personnel may |

|

result in misplacing of internal wires and components which could cause serious hazard. We recommend that all tool service be performed by a Dremel Service Facility.

CARBON BRUSHES

The brushes and commutator in your tool have been engineered for many hours of dependable service. In order to prepare your brushes for use, run your tool at full speed for 5 minutes under no load. This will properly “seat” your brushes, which extends the life of both your brushes and your tool. To maintain peak efficiency of the motor, we recommend every 50 - 60 hours the brushes be examined. Only genuine Dremel replacement brushes specially designed for your tool should be used.

MAINTENANCE OF REPLACEABLE BRUSHES ON MODEL F013039519

The brushes should be inspected frequently when tools are used continuously. If your tool runs sporadically, loses power, makes unusual noises or runs at a reduced speed, check the brushes. To continue using the tool in this condition will permanently damage your tool.

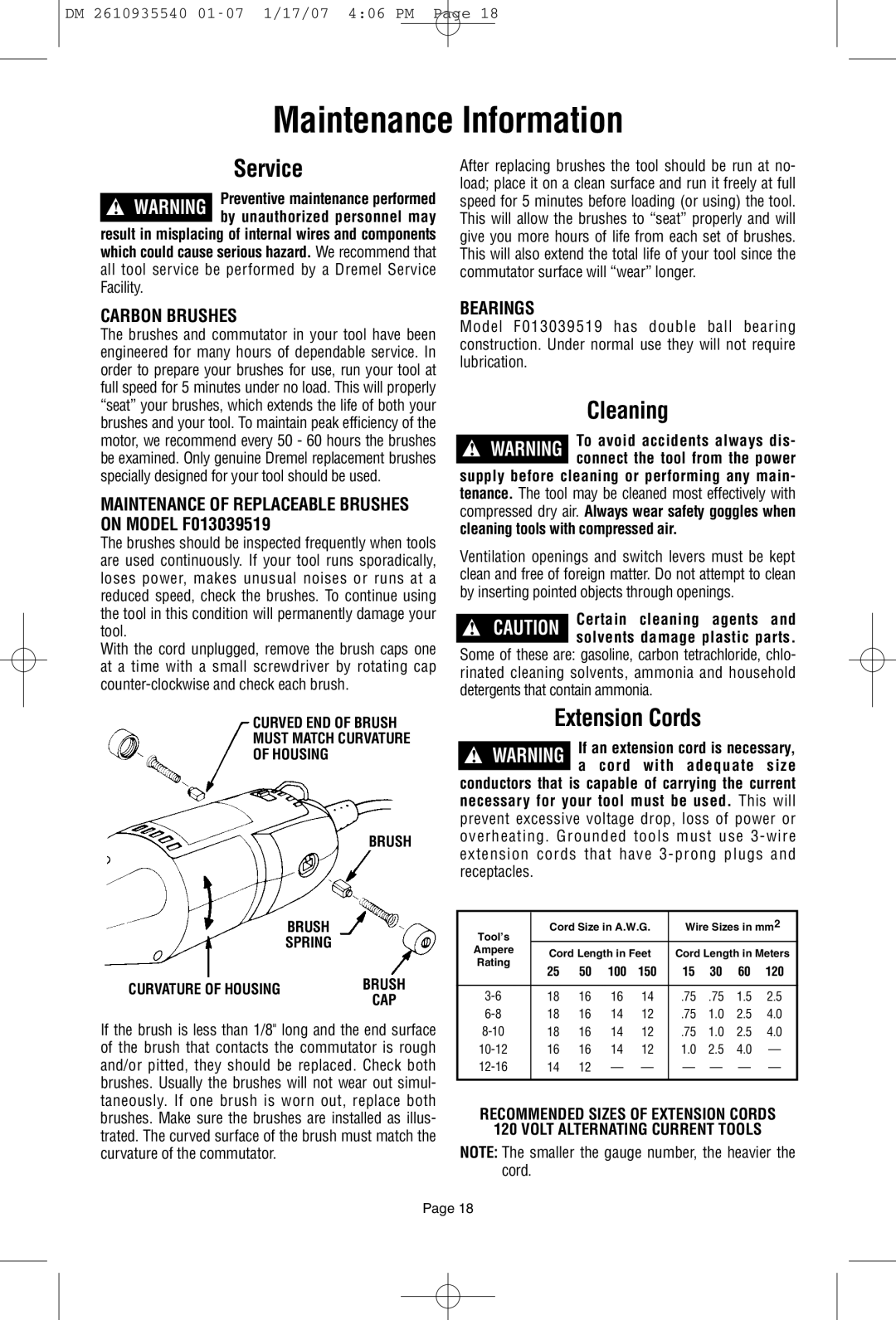

With the cord unplugged, remove the brush caps one at a time with a small screwdriver by rotating cap

CURVED END OF BRUSH

MUST MATCH CURVATURE

OF HOUSING

BRUSH

BRUSH

SPRING

| BRUSH | |

CURVATURE OF HOUSING | ||

CAP | ||

|

If the brush is less than 1/8" long and the end surface of the brush that contacts the commutator is rough and/or pitted, they should be replaced. Check both brushes. Usually the brushes will not wear out simul- taneously. If one brush is worn out, replace both brushes. Make sure the brushes are installed as illus- trated. The curved surface of the brush must match the curvature of the commutator.

After replacing brushes the tool should be run at no- load; place it on a clean surface and run it freely at full speed for 5 minutes before loading (or using) the tool. This will allow the brushes to “seat” properly and will give you more hours of life from each set of brushes. This will also extend the total life of your tool since the commutator surface will “wear” longer.

BEARINGS

Model F013039519 has double ball bearing construction. Under normal use they will not require lubrication.

Cleaning

!To avoid accidents always dis- WARNING connect the tool from the power

supply before cleaning or performing any main- tenance. The tool may be cleaned most effectively with compressed dry air. Always wear safety goggles when cleaning tools with compressed air.

Ventilation openings and switch levers must be kept clean and free of foreign matter. Do not attempt to clean by inserting pointed objects through openings.

!Certain cleaning agents and CAUTION solvents damage plastic parts.

Some of these are: gasoline, carbon tetrachloride, chlo- rinated cleaning solvents, ammonia and household detergents that contain ammonia.

Extension Cords

! WARNING | If an extension cord is necessary, |

| a cord with adequate size |

|

conductors that is capable of carrying the current necessary for your tool must be used. This will prevent excessive voltage drop, loss of power or overheating. Grounded tools must use

Tool’s | Cord Size in A.W.G. | Wire Sizes in mm2 | |||||||

Ampere | Cord Length in Feet | Cord Length in Meters | |||||||

Rating | |||||||||

25 | 50 | 100 | 150 | 15 | 30 | 60 | 120 | ||

| |||||||||

|

|

|

|

|

|

|

|

| |

18 | 16 | 16 | 14 | .75 | .75 | 1.5 | 2.5 | ||

18 | 16 | 14 | 12 | .75 | 1.0 | 2.5 | 4.0 | ||

18 | 16 | 14 | 12 | .75 | 1.0 | 2.5 | 4.0 | ||

16 | 16 | 14 | 12 | 1.0 | 2.5 | 4.0 | — | ||

14 | 12 | — | — | — | — | — | — | ||

|

|

|

|

|

|

|

|

| |

RECOMMENDED SIZES OF EXTENSION CORDS 120 VOLT ALTERNATING CURRENT TOOLS

NOTE: The smaller the gauge number, the heavier the cord.

Page 18