DM 2610935540

chuck it may loosen and fly out during use possibly striking you or bystanders.

To replace or attach the keyless chuck accessory to your MultiPro rotary tool, unplug the tool and engage the shaft lock button then remove the collet and collet nut. Thread the keyless chuck on the end of the shaft. Engage the shaft lock button again, insert the accessory shank into the chuck and finger tighten until the shank is secure.

For small size drill bits, close the chuck to the point where the bit will just fit in; then tighten securely. This helps center the bit in the keyless chuck correctly. In some high force applications such as removing metal, tile cutting or routing, the bit (tungsten carbide cutters, high speed cutters, router bits or tile cutters) and chuck will become hot if overloaded for extended

periods of time. Overloading the chuck may cause the bit to loosen and slip. It is recommended that in these types of applications that the bit be secured in the chuck with the supplied wrench and work in intervals to allow cooling of the bit and chuck. If the bit slips the tool will begin to vibrate excessively, this is an indication that you should shut the tool off, re- position and tighten the bit then allow the tool to run

The chuck should be cleaned occasionally to keep it functioning properly. Simply remove the chuck from the tool and gently tap the tip of the chuck on a fat surface to remove any loose debris. In some applications the keyless chuck may tighten up during use. If this occurs, gently loosen using the wrench included in your rotary tool kit.

Operating Instructions

The Rotary Tool is a handful of

The Rotary Tool has a small, powerful electric universal motor, is comfortable in the hand, and is made to accept a large variety of accessories including abrasive wheels, drill bits, wire brushes, polishers, engraving cutters, router bits, cutting wheels and attachments. Accessories come in a variety of shapes and permit you to do a number of different jobs. As you become familiar with the range of accessories and their uses, you will learn just how versatile the Rotary Tool is. You’ll see dozens of uses you hadn’t thought of before.

The real secret of the Rotary Tool is its speed. To understand the advantages of its high speed, you have to know that the standard portable electric drill runs at speeds up to 2,800 revolutions per minute. The Rotary Tool operates at speeds up to 35,000 revolutions per minute. The typical electric drill is a

It is this high speed, along with its compact size and wide variety of special accessories and attachments, that makes the Rotary Tool different from other tools. The speed enables it to do jobs low speed tools cannot do, such as cutting hardened steel, engraving glass, etc.

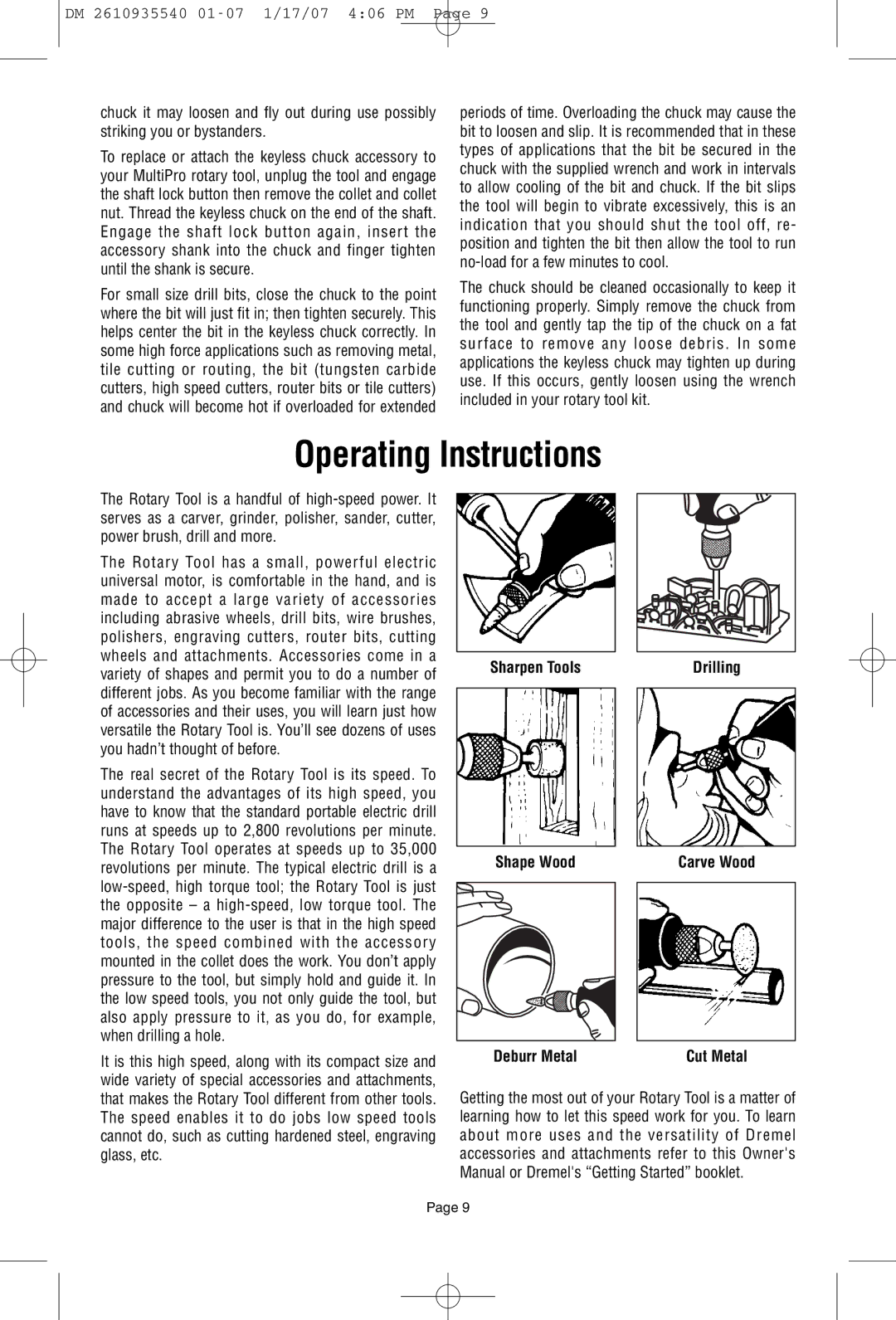

Sharpen Tools | Drilling |

Shape Wood |

| Carve Wood |

|

|

|

|

|

|

Deburr Metal | Cut |

Getting the most out of your Rotary Tool is a matter of learning how to let this speed work for you. To learn about more uses and the versatility of Dremel accessories and attachments refer to this Owner's Manual or Dremel's “Getting Started” booklet.

Page 9