Electrical noise from the engine's wiring, bilge pumps, VHF radio wires and cables, and aerators can be picked up by the sonar. Use caution when routing the transducer cable around these wires.

WARNING:

Clamp the transducer cable to the transom close to the transducer. This can prevent the transducer from enter- ing the boat if it is knocked off at high speed.

If you need to drill a hole in the transom to pass the connector through, the required hole size is 5/8".

Caution:

If you drill a hole in the transom for the cable, make sure it is located above the waterline. After installation, be sure to seal the hole with the same marine grade above- or

7.Make a test run to determine the results. If the bottom is lost at high speed, or if noise appears on the display, try sliding the trans- ducer bracket down. This puts the transducer deeper into the water, hopefully below the turbulence causing the noise. Don't allow the transducer bracket to go below the bottom of the hull.

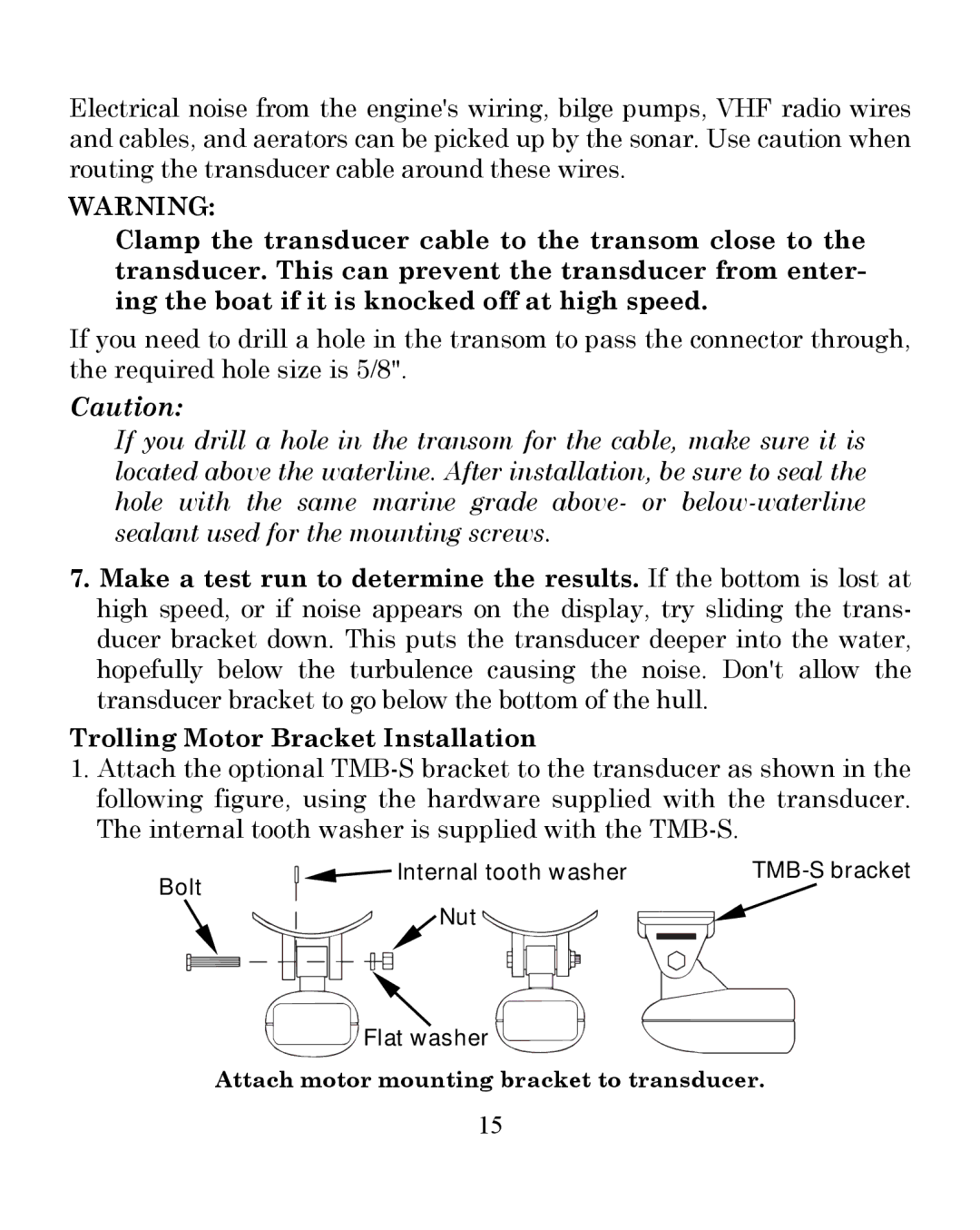

Trolling Motor Bracket Installation

1.Attach the optional

Bolt | Internal tooth washer | |

|

|

![]() Nut

Nut ![]()

![]() Flat washer

Flat washer ![]()

Attach motor mounting bracket to transducer.

15