■ Electrical Parts List | |

| |

|

|

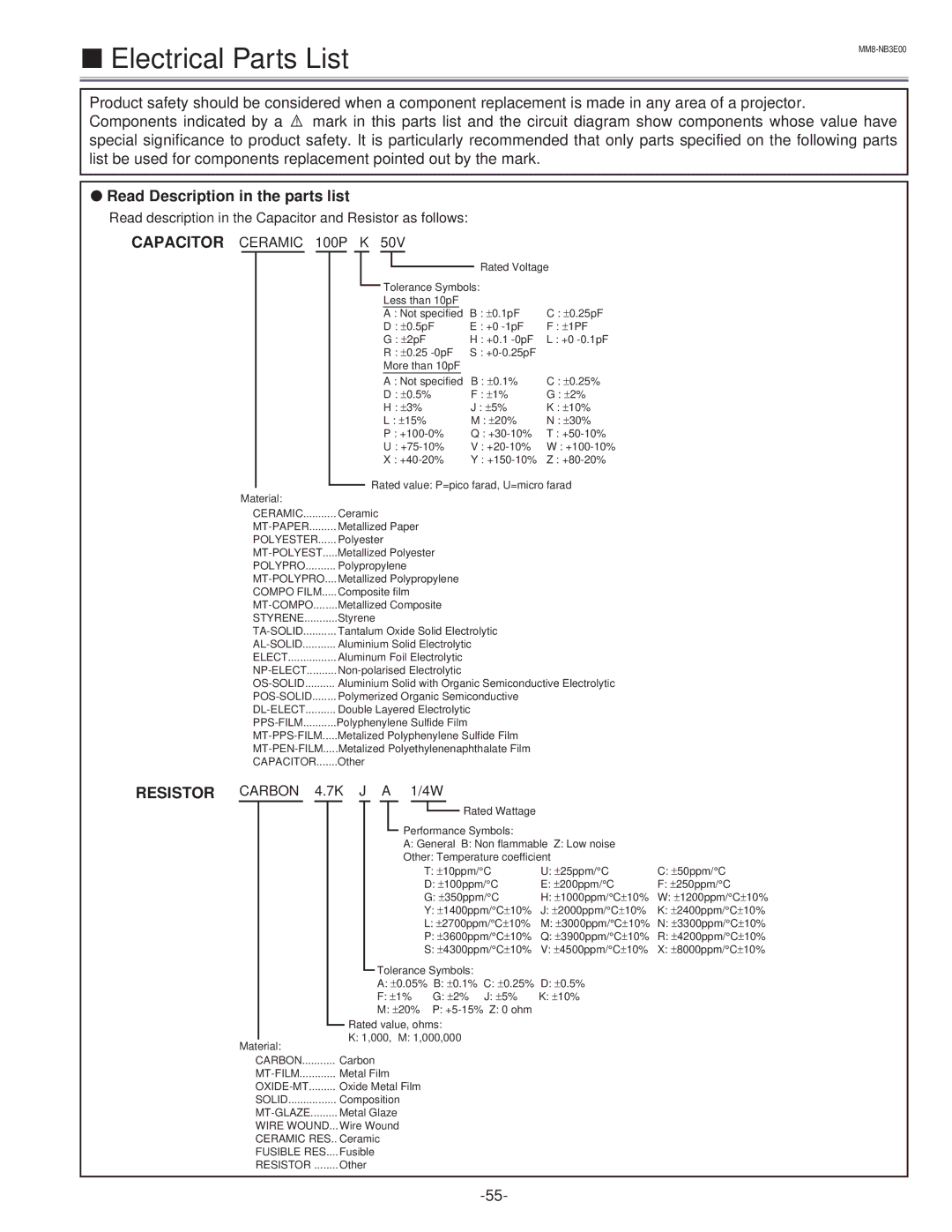

Product safety should be considered when a component replacement is made in any area of a projector. Components indicated by a ! mark in this parts list and the circuit diagram show components whose value have special significance to product safety. It is particularly recommended that only parts specified on the following parts list be used for components replacement pointed out by the mark.

●Read Description in the parts list

Read description in the Capacitor and Resistor as follows:

CAPACITOR CERAMIC 100P K 50V

|

|

|

|

|

|

|

|

|

|

|

|

| Rated Voltage | |

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

| Tolerance Symbols: |

| |||||

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

| Less than 10pF | B : ±0.1pF | C : ±0.25pF | ||||

|

|

|

|

|

|

|

| A : Not specified | ||||||

|

|

|

|

|

|

|

| D : ±0.5pF | E : +0 | F : ±1PF | ||||

|

|

|

|

|

|

|

| G : ±2pF | H : +0.1 | L : +0 | ||||

|

|

|

|

|

|

|

| R : ±0.25 |

| |||||

|

|

|

|

|

|

|

| More than 10pF |

|

|

|

| ||

|

|

|

|

|

|

|

| A : Not specified | B : ±0.1% | C : ±0.25% | ||||

|

|

|

|

|

|

|

| D : ±0.5% | F : ±1% | G : ±2% | ||||

|

|

|

|

|

|

|

| H : ±3% | J : ±5% | K : ±10% | ||||

|

|

|

|

|

|

|

| L : ±15% | M : ±20% | N : ±30% | ||||

|

|

|

|

|

|

|

| P : | Q : | T : | ||||

|

|

|

|

|

|

|

| U : | V : | W : | ||||

|

|

|

|

|

|

|

| X : | Y : | Z : | ||||

|

|

|

|

|

| Rated value: P=pico farad, U=micro farad | ||||||||

Material: |

|

|

| |||||||||||

|

|

|

|

|

|

|

|

|

|

|

| |||

CERAMIC | Ceramic |

|

|

| ||||||||||

Metallized Paper |

|

|

| |||||||||||

POLYESTER | Polyester |

|

|

| ||||||||||

Metallized Polyester |

|

|

| |||||||||||

POLYPRO | Polypropylene |

|

|

| ||||||||||

Metallized Polypropylene |

|

|

| |||||||||||

COMPO FILM | Composite film |

|

|

| ||||||||||

Metallized Composite |

|

|

| |||||||||||

STYRENE | Styrene |

|

|

| ||||||||||

Tantalum Oxide Solid Electrolytic |

| |||||||||||||

Aluminium Solid Electrolytic |

| |||||||||||||

ELECT | Aluminum Foil Electrolytic |

|

|

| ||||||||||

|

|

| ||||||||||||

Aluminium Solid with Organic Semiconductive Electrolytic | ||||||||||||||

Polymerized Organic Semiconductive |

| |||||||||||||

Double Layered Electrolytic |

| |||||||||||||

Polyphenylene Sulfide Film |

|

|

| |||||||||||

Metalized Polyphenylene Sulfide Film |

| |||||||||||||

Metalized Polyethylenenaphthalate Film |

| |||||||||||||

CAPACITOR | Other |

|

|

| ||||||||||

RESISTOR CARBON 4.7K J A 1/4W

![]() Rated Wattage

Rated Wattage

Performance Symbols:

A:General B: Non flammable Z: Low noise Other: Temperature coefficient

T: ±10ppm/°C | U: ±25ppm/°C | C: ±50ppm/°C |

D: ±100ppm/°C | E: ±200ppm/°C | F: ±250ppm/°C |

G: ±350ppm/°C | H: ±1000ppm/°C±10% | W: ±1200ppm/°C±10% |

Y:±1400ppm/°C±10% J: ±2000ppm/°C±10% K: ±2400ppm/°C±10%

L:±2700ppm/°C±10% M: ±3000ppm/°C±10% N: ±3300ppm/°C±10%

P:±3600ppm/°C±10% Q: ±3900ppm/°C±10% R: ±4200ppm/°C±10%

S:±4300ppm/°C±10% V: ±4500ppm/°C±10% X: ±8000ppm/°C±10%

|

|

|

|

| Tolerance Symbols: | |

|

|

|

|

| ||

|

|

|

|

| A: ±0.05% B: ±0.1% C: ±0.25% D: ±0.5% | |

|

|

|

|

| F: ±1% | G: ±2% J: ±5% K: ±10% |

|

|

|

|

| M: ±20% | P: |

|

|

| Rated value, ohms: | |||

|

|

| ||||

Material: |

| K: 1,000, M: 1,000,000 | ||||

|

|

|

|

| ||

CARBON | Carbon |

| ||||

Metal Film |

| |||||

Oxide Metal Film |

| |||||

SOLID | Composition |

| ||||

Metal Glaze |

| |||||

WIRE WOUND... | Wire Wound |

| ||||

CERAMIC RES.. Ceramic |

| |||||

FUSIBLE RES.... | Fusible |

| ||||

RESISTOR | Other |

| ||||