DOWNROD

SETSCREW

MOTOR

Figure 19

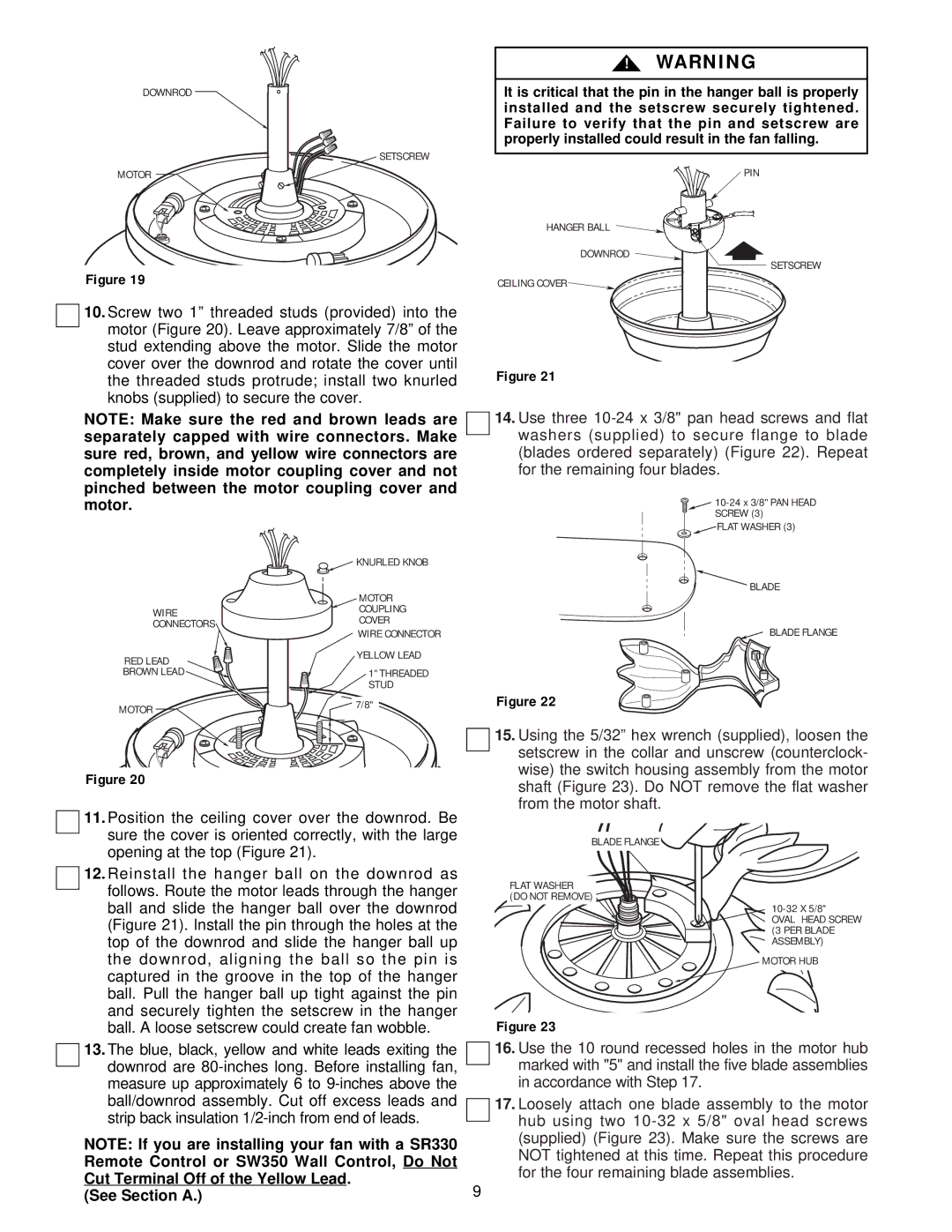

10.Screw two 1” threaded studs (provided) into the motor (Figure 20). Leave approximately 7/8” of the stud extending above the motor. Slide the motor cover over the downrod and rotate the cover until the threaded studs protrude; install two knurled knobs (supplied) to secure the cover.

NOTE: Make sure the red and brown leads are separately capped with wire connectors. Make sure red, brown, and yellow wire connectors are completely inside motor coupling cover and not pinched between the motor coupling cover and motor.

!WARNING

It is critical that the pin in the hanger ball is properly installed and the setscrew securely tightened. Failure to verify that the pin and setscrew are properly installed could result in the fan falling.

PIN

PIN

HANGER BALL

DOWNROD

SETSCREW

CEILING COVER ![]()

Figure 21

14.Use three

![]()

![]()

SCREW (3)

![]() FLAT WASHER (3)

FLAT WASHER (3)

WIRE

CONNECTORS

RED LEAD

BROWN LEAD

MOTOR

![]() KNURLED KNOB

KNURLED KNOB

MOTOR

COUPLING

COVER

WIRE CONNECTOR

YELLOW LEAD

1" THREADED STUD

![]() 7/8"

7/8"

BLADE

BLADE FLANGE

Figure 22

Figure 20

11.Position the ceiling cover over the downrod. Be sure the cover is oriented correctly, with the large opening at the top (Figure 21).

12.Reinstall the hanger ball on the downrod as follows. Route the motor leads through the hanger ball and slide the hanger ball over the downrod (Figure 21). Install the pin through the holes at the top of the downrod and slide the hanger ball up the downrod, aligning the ball so the pin is captured in the groove in the top of the hanger ball. Pull the hanger ball up tight against the pin and securely tighten the setscrew in the hanger ball. A loose setscrew could create fan wobble.

13.The blue, black, yellow and white leads exiting the downrod are

NOTE: If you are installing your fan with a SR330 Remote Control or SW350 Wall Control, Do Not Cut Terminal Off of the Yellow Lead.

(See Section A.)

15.Using the 5/32” hex wrench (supplied), loosen the setscrew in the collar and unscrew (counterclock- wise) the switch housing assembly from the motor shaft (Figure 23). Do NOT remove the flat washer from the motor shaft.

BLADE FLANGE

FLAT WASHER (DO NOT REMOVE)

OVAL HEAD SCREW (3 PER BLADE ASSEMBLY)

MOTOR HUB

Figure 23

16.Use the 10 round recessed holes in the motor hub marked with "5" and install the five blade assemblies in accordance with Step 17.

17.Loosely attach one blade assembly to the motor hub using two

9