Preparation

4.0PREPARATION

These installation instructions provide all the information needed for positioning the Nfinity Mainte- nance Bypass Cabinet (including environmental requirements) and for connecting the input and out- put power cables.

4.1Inspection

Upon receiving the Nfinity Maintenance Bypass Cabinet, examine the packaging for any signs of mis- handling or damage. If any damage is noted, contact your local dealer or Liebert representative and notify your carrier.

4.2Environment

The Maintenance Bypass Cabinet environment must be free of conductive contaminants and exces- sive moisture (water condensation), flammable vapors, chemical fumes, or corrosive gases and liquids.

4.3Required Setup Equipment

The tools below are required in order to properly setup your maintenance bypass cabinet:

•pallet jack

•1/2" (13 mm) wrench

•torque wrench

•

•#2 Phillips screwdriver

•3/16" (5 mm) Allen wrench

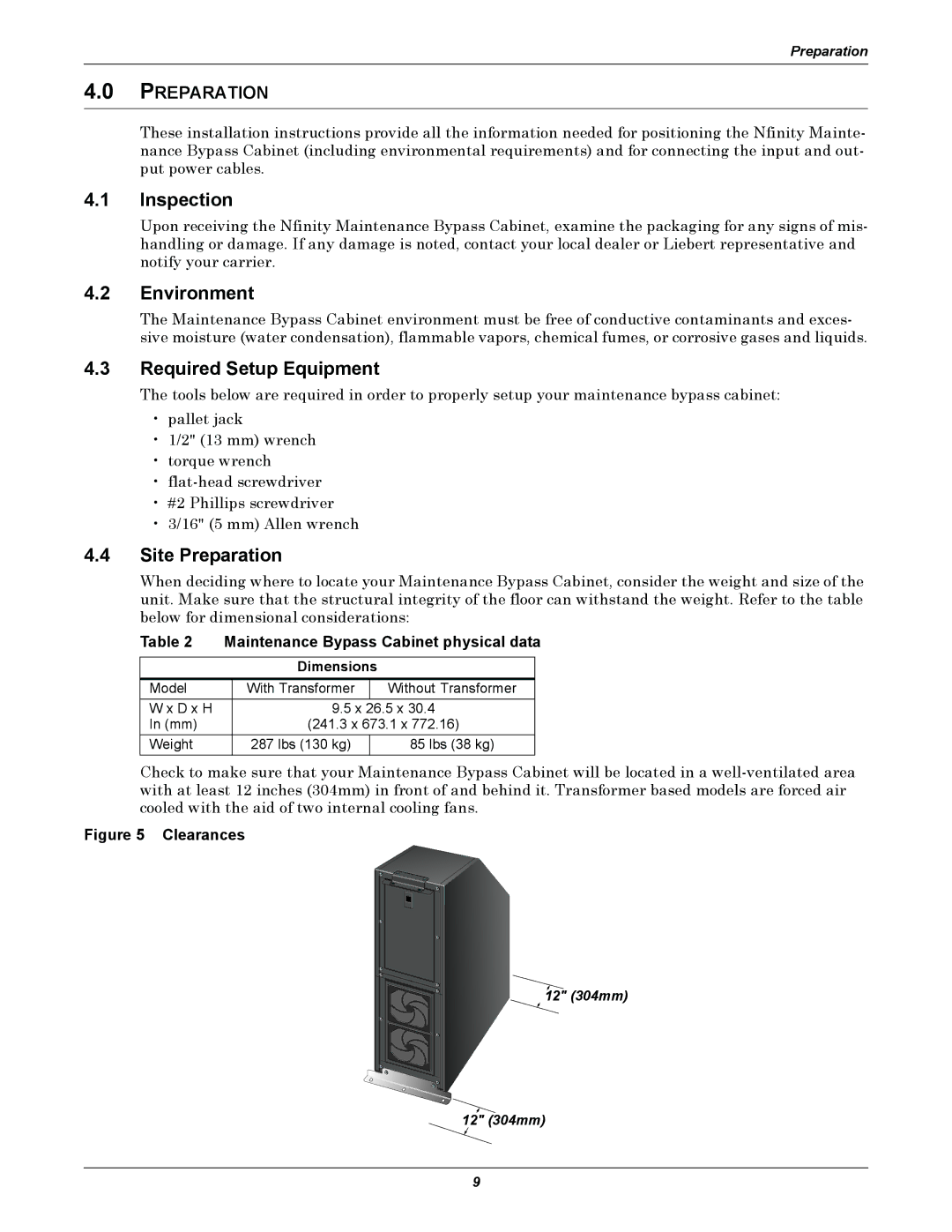

4.4Site Preparation

When deciding where to locate your Maintenance Bypass Cabinet, consider the weight and size of the unit. Make sure that the structural integrity of the floor can withstand the weight. Refer to the table below for dimensional considerations:

Table 2 | Maintenance Bypass Cabinet physical data | ||||

|

|

|

|

|

|

|

| Dimensions |

|

| |

Model |

| With Transformer |

| Without Transformer |

|

W x D x H |

| 9.5 x | 26.5 x 30.4 |

| |

In (mm) |

| (241.3 x 673.1 x 772.16) |

| ||

Weight |

| 287 lbs (130 kg) |

| 85 lbs (38 kg) |

|

Check to make sure that your Maintenance Bypass Cabinet will be located in a

Figure 5 Clearances

12" (304mm)

12" (304mm)

9