Operation |

3.0Operation

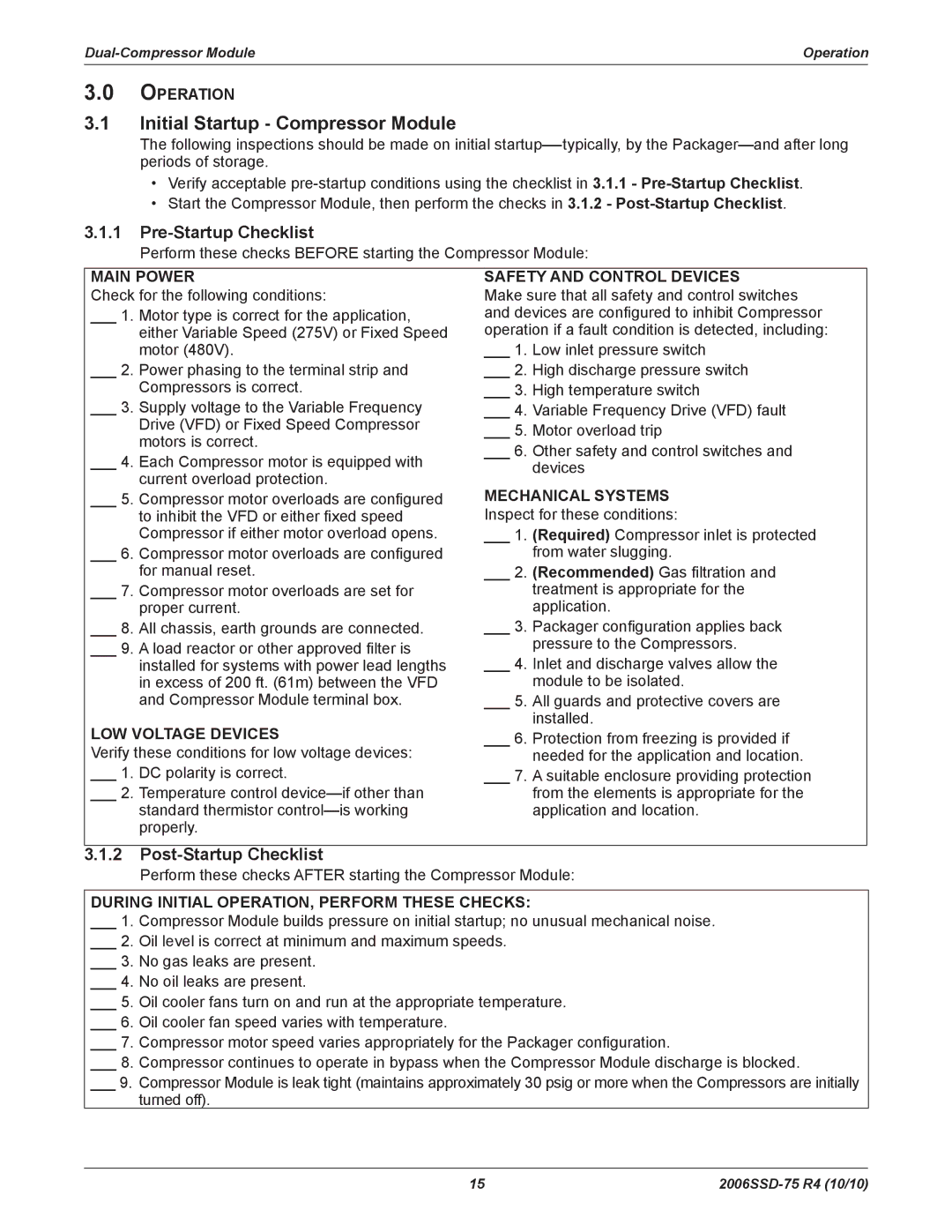

3.1Initial Startup - Compressor Module

The following inspections should be made on initial

•Verify acceptable

•Start the Compressor Module, then perform the checks in 3.1.2 -

3.1.1Pre-Startup Checklist

Perform these checks BEFORE starting the Compressor Module:

MAIN POWER

Check for the following conditions:

___ 1. Motor type is correct for the application, either Variable Speed (275V) or Fixed Speed motor (480V).

___ 2. Power phasing to the terminal strip and Compressors is correct.

___ 3. Supply voltage to the Variable Frequency Drive (VFD) or Fixed Speed Compressor motors is correct.

___ 4. Each Compressor motor is equipped with current overload protection.

___ 5. Compressor motor overloads are configured to inhibit the VFD or either fixed speed Compressor if either motor overload opens.

___ 6. Compressor motor overloads are configured for manual reset.

___ 7. Compressor motor overloads are set for proper current.

___ 8. All chassis, earth grounds are connected.

___ 9. A load reactor or other approved filter is installed for systems with power lead lengths in excess of 200 ft. (61m) between the VFD and Compressor Module terminal box.

LOW VOLTAGE DEVICES

Verify these conditions for low voltage devices:

___ 1. DC polarity is correct.

___ 2. Temperature control

SAFETY AND CONTROL DEVICES

Make sure that all safety and control switches and devices are configured to inhibit Compressor operation if a fault condition is detected, including:

___ 1. Low inlet pressure switch

___ 2. High discharge pressure switch

___ 3. High temperature switch

___ 4. Variable Frequency Drive (VFD) fault

___ 5. Motor overload trip

___ 6. Other safety and control switches and devices

MECHANICAL SYSTEMS

Inspect for these conditions:

___ 1. (Required) Compressor inlet is protected from water slugging.

___ 2. (Recommended) Gas filtration and treatment is appropriate for the application.

___ 3. Packager configuration applies back pressure to the Compressors.

___ 4. Inlet and discharge valves allow the module to be isolated.

___ 5. All guards and protective covers are installed.

___ 6. Protection from freezing is provided if needed for the application and location.

___ 7. A suitable enclosure providing protection from the elements is appropriate for the application and location.

3.1.2Post-Startup Checklist

Perform these checks AFTER starting the Compressor Module:

DURING INITIAL OPERATION, PERFORM THESE CHECKS:

___ 1. Compressor Module builds pressure on initial startup; no unusual mechanical noise.

___ 2. Oil level is correct at minimum and maximum speeds.

___ 3. No gas leaks are present.

___ 4. No oil leaks are present.

___ 5. Oil cooler fans turn on and run at the appropriate temperature.

___ 6. Oil cooler fan speed varies with temperature.

___ 7. Compressor motor speed varies appropriately for the Packager configuration.

___ 8. Compressor continues to operate in bypass when the Compressor Module discharge is blocked.

___ 9. Compressor Module is leak tight (maintains approximately 30 psig or more when the Compressors are initially turned off).

15 |